Are you familiar with the term PWM connector? If not, don’t worry – you’re not alone! The world of mobile accessories can be quite vast and complex, with a plethora of terms and jargon that can be overwhelming to newcomers.

So, what exactly is a PWM connector? PWM stands for “Pulse Width Modulation,” which is a technique used to control the power output of electronic devices. In the context of mobile accessories, a PWM connector refers to a specific type of connector used in devices like power banks, wireless chargers, and other accessories.

In this article, we will delve deeper into the world of PWM connectors, exploring their purpose, functionality, and the benefits they offer. From understanding the basics to unraveling their significance in the mobile accessory industry, we will provide you with a comprehensive guide that will demystify the concept of PWM connectors.

Inside This Article

- PWM Connector: An Overview

- Understanding PWM (Pulse Width Modulation)

- Importance of PWM Connectors in Electronics

- How PWM Connectors Function in Different Devices

- Conclusion

- FAQs

PWM Connector: An Overview

A PWM connector, also known as a Pulse Width Modulation connector, is a type of electrical connection used in computer systems. It is specifically designed to control the speed of fans and other cooling devices. PWM connectors are commonly found on computer motherboards and fan controllers. They play a crucial role in maintaining optimal temperatures and preventing overheating.

The purpose of a PWM connector is to regulate the power supplied to the connected device, such as a fan. It achieves this by rapidly switching the power on and off at varying duty cycles. The duty cycle of a PWM signal determines the percentage of time the power is on during each cycle. By adjusting the duty cycle, the connector can effectively control the speed of the fan or the intensity of other connected devices.

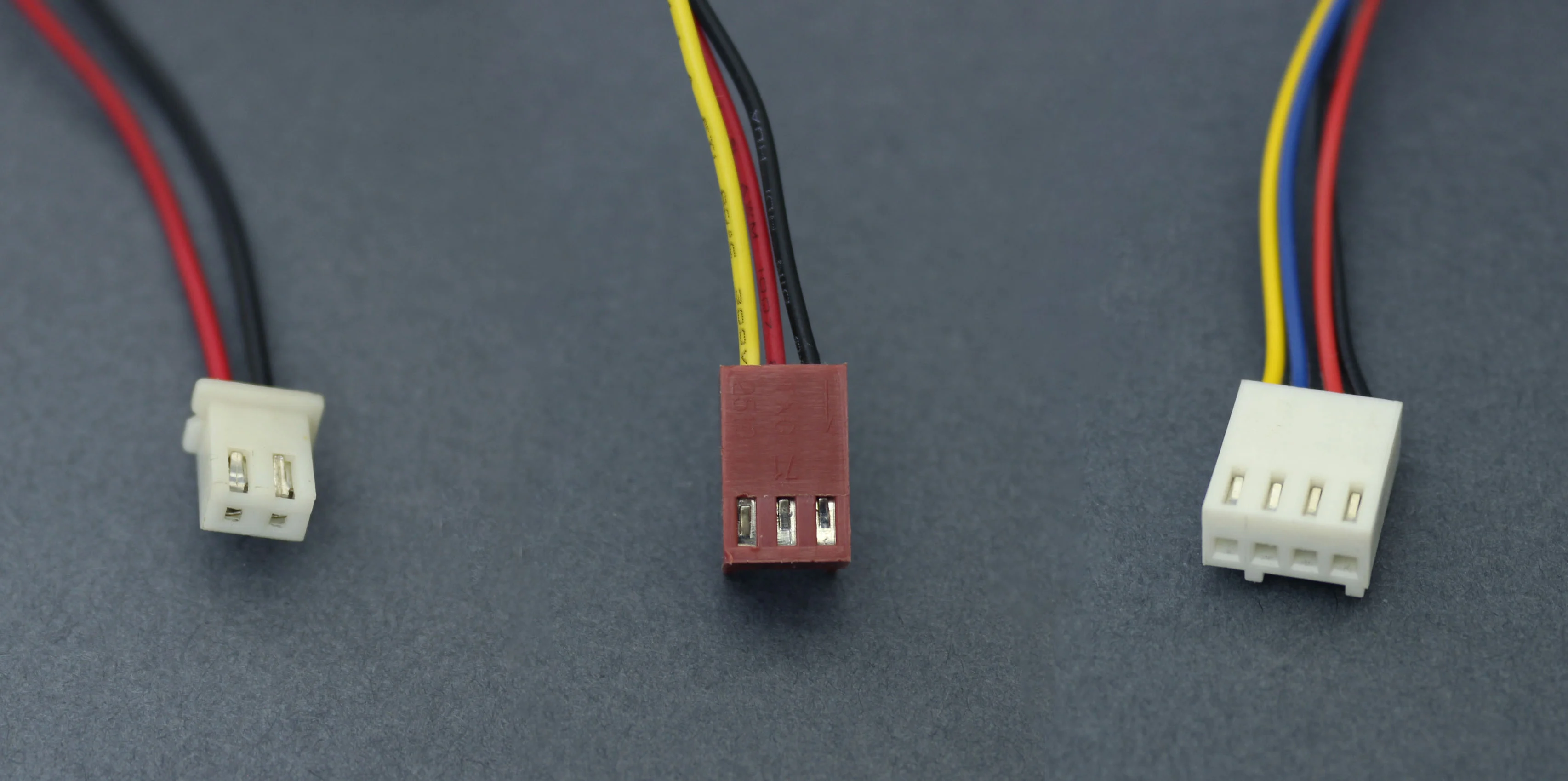

A PWM connector consists of several pins or leads that transmit power and signals between the motherboard and the connected device. The number of pins may vary depending on the specific connector type and manufacturer. Generally, a PWM connector includes at least three pins: power, ground, and control. Some connectors may also have additional pins for tachometer readings and sensor inputs.

The power pin of a PWM connector supplies the necessary voltage to operate the connected device. The ground pin provides the return path for the electrical current. The control pin carries the PWM signal from the motherboard or fan controller to regulate the speed or intensity. In some cases, the control pin may be labeled as a PWM pin or simply marked with a fan symbol.

PWM connectors are generally compatible with PWM-enabled fans and devices. However, it is important to ensure compatibility between the connector and the device before making a connection. It is recommended to check the motherboard or fan controller’s specifications and the device’s user manual for proper compatibility.

Understanding PWM (Pulse Width Modulation)

Pulse Width Modulation (PWM) is a widely used technique in electronics and electrical engineering. It involves varying the width of a digital signal to control the amount of power delivered to a device or component. PWM signals are commonly used in applications such as motor speed control, LED dimming, and audio amplification.

The basic concept behind PWM is to create a square wave signal with a fixed frequency, where the duty cycle (the ratio of pulse width to period) determines the effective voltage or power level. By adjusting the duty cycle, the average power delivered to the device can be controlled, allowing for precise regulation of its operation.

One of the key advantages of PWM is its efficiency. By rapidly switching the power on and off at a high frequency, the average power delivered can be adjusted without dissipating excess energy as heat. This makes PWM an ideal method for controlling power-hungry devices while minimizing energy wastage.

In PWM systems, a PWM controller generates the square wave signal and adjusts the duty cycle based on the desired output. This controller can be a microcontroller, a dedicated PWM IC, or a part of a larger system, depending on the application. The PWM signal is then sent through a PWM connector to the device or component that needs to be controlled.

A PWM connector is a specialized type of connector that allows for the transfer of the PWM signal between the PWM controller and the target device. It typically consists of multiple pins or terminals, each dedicated to transmitting a specific part of the PWM signal, such as the positive voltage, ground, and control signal.

One of the key components of a PWM connector is the PWM pin, which carries the PWM signal generated by the controller. This pin is usually marked with a specific label, such as “PWM” or “PWM Out,” to indicate its purpose. Other pins may include the positive voltage (VCC), the ground (GND), and additional control signals, depending on the specific requirements of the system.

When connecting a device or component to a PWM connector, it is essential to ensure compatibility between the connector and the target device. This includes matching the pin configuration, voltage levels, and signal requirements. Mismatched connectors can result in improper signaling, potential damage to the connected devices, or even system failure.

Importance of PWM Connectors in Electronics

Pulse Width Modulation (PWM) connectors play a crucial role in modern electronics, offering precise control over the power and speed of various devices. These connectors are specifically designed to regulate the amount of electricity delivered to components, allowing for efficient operation and optimal performance.

One of the primary reasons for the importance of PWM connectors is their ability to provide variable voltage or current signals. By adjusting the duty cycle, or the proportion of on-time to off-time, these connectors can deliver a wide range of power outputs. This flexibility is particularly valuable in applications where precise control over speed, brightness, or intensity is required.

Another key aspect of PWM connectors is their compatibility with various devices and systems. Whether used in computer cooling fans, LED lighting systems, or motor control units, these connectors ensure seamless integration and reliable performance. Their versatility makes them a vital component in countless electronic applications, enabling smooth functionality across different devices and sectors.

Efficiency is another critical factor when it comes to PWM connectors. By regulating the power delivered to a device, these connectors help reduce energy consumption and heat generation. This is especially beneficial in battery-powered devices and environments where heat dissipation is a concern. By optimizing power delivery, PWM connectors contribute to longer battery life and overall system efficiency.

The importance of PWM connectors in electronics is further highlighted in their role in noise reduction. By controlling the power provided to certain components, these connectors can minimize electrical noise and interference, ensuring clean and stable signal transmission. This is especially critical in sensitive applications like audio systems or data communication, where even small disruptions can degrade performance.

How PWM Connectors Function in Different Devices

Pulse Width Modulation (PWM) connectors are essential components that play a crucial role in the functioning of various electronic devices. These connectors are widely used in devices where precise control of power delivery is required, such as computer fans, LED lights, motor controllers, and more. In this article, we will explore how PWM connectors function in different devices and their significance in ensuring optimal performance.

At its core, a PWM connector works by rapidly switching the power supply on and off at varying pulse widths. This modulation of the power signal allows for precise control over the amount of power delivered to the connected device. By adjusting the width of the pulses, the amount of power can be regulated, resulting in different levels of output.

One of the primary applications of PWM connectors is in computer fans. These connectors are used to control the fan speed based on the temperature of the system. By adjusting the pulse width, the fan speed can be increased or decreased, effectively managing the system’s cooling requirements. This feature not only helps maintain optimal operating temperatures but also reduces noise levels as the fan speed adjusts according to the workload.

Similarly, PWM connectors are commonly found in LED lights. LED brightness can be controlled by adjusting the amount of current flowing through them. PWM connectors enable dimming or brightening of LED lights by varying the pulse width. This capability allows users to customize the lighting ambiance as per their preferences, making them highly desirable for home and commercial lighting applications.

Motor controllers in various devices, such as robotics and industrial machinery, also rely on PWM connectors. These connectors enable precise control over the motor’s speed and direction. By adjusting the pulse width, the voltage delivered to the motor can be modified, resulting in a change in speed or movement. This fine-grained control is essential for tasks that require accurate and variable motor performance.

Compatibility is a crucial aspect to consider when it comes to PWM connectors. These connectors typically have a 4-pin configuration with specific voltage and ground pins, along with a PWM pin. However, it’s important to note that different devices may have variations in their connector designs or pin configurations. It is vital to ensure that the PWM connector being used is compatible with the device to avoid any potential damage or malfunction.

Conclusion

In conclusion, the PWM connector is an essential component in modern electronics, particularly in the field of computer cooling systems. Its ability to regulate fan speeds based on temperature variations ensures optimal performance and prevents overheating. Understanding the function and compatibility of the PWM connector is crucial for anyone involved in computer building, troubleshooting, or upgrading.

By providing a means to control fan speeds efficiently, the PWM connector offers a more reliable and quieter cooling solution. It enables the customization of cooling profiles, allowing users to strike the perfect balance between performance and noise levels. Whether you are a hardcore gamer, a video editor, or simply a casual computer user, the PWM connector plays a vital role in maintaining the longevity and stability of your system.

As technology advances, the importance of PWM connectors in various devices is only bound to increase. Keeping up to date with the latest developments and understanding how to harness the power of these connectors will undoubtedly benefit any tech enthusiast or professional in the field of electronics.

FAQs

1. What is a PWM connector?

A PWM connector, also known as a Pulse Width Modulation connector, is a type of connector used in electronic systems to control the speed of devices such as fans and pumps. It allows for precise adjustments in the voltage supplied to the device, resulting in variable speed control.

2. How does a PWM connector work?

A PWM connector works by rapidly cycling the power on and off to the connected device. The speed of the device is controlled by adjusting the ratio of on-time to off-time. By increasing or decreasing the duty cycle, which is the percentage of time the power is on, the speed of the device can be adjusted accordingly.

3. What are the advantages of using a PWM connector?

Using a PWM connector provides several advantages. Firstly, it allows for precise control over the speed of devices, enabling optimal performance and energy efficiency. Additionally, the ability to vary the speed of devices like fans can help in maintaining a quieter operating environment. PWM connectors are widely used in computer cooling systems, where temperature regulation is crucial.

4. Can I use a PWM connector with any device?

PWM connectors are mainly used with devices that require variable speed control, such as fans and pumps. However, it’s important to note that not all devices are compatible with PWM connectors. Before using a PWM connector, it’s advisable to check the device specifications and ensure compatibility.

5. Are PWM connectors compatible with all motherboards?

Most modern motherboards come with PWM fan headers that support PWM connectors. However, it’s always recommended to check the motherboard manual or specifications to confirm compatibility. In some cases, older motherboards or budget-friendly models may only have headers for traditional 3-pin connectors, which are not compatible with PWM connectors.