Are you familiar with FPC connectors? If not, you’re in the right place. FPC connectors, also known as Flexible Printed Circuit connectors, play a crucial role in the world of mobile accessories. These connectors provide a reliable and efficient means of connecting electronic components in devices such as smartphones, tablets, and wearable gadgets.

In this article, we will dive deep into the world of FPC connectors, exploring what they are, how they work, and why they are essential in the realm of mobile accessories. Whether you’re a tech enthusiast or someone looking to gain a better understanding of the inner workings of your favorite gadgets, this article will provide you with valuable insights into the significance of FPC connectors in the world of mobile technology.

So, let’s unravel the mysteries behind FPC connectors and discover their importance in our modern, interconnected world.

Inside This Article

- FPC Connector Basics

- Types of FPC Connectors

- Advantages of FPC Connectors

- Common Applications of FPC Connectors

- Conclusion

- FAQs

FPC Connector Basics

An FPC (Flexible Printed Circuit) connector, also known as a flex connector or ribbon connector, is a type of electrical connector that is specifically designed for use with flexible circuits. It provides a reliable and secure connection between a flexible circuit board and another electrical device or circuit. FPC connectors are widely used in various electronic devices to facilitate the transmission of signals and power.

FPC connectors are composed of two main components: the connector housing and the contact terminals. The connector housing is usually made of plastic and serves as the protective shell for the contact terminals. The contact terminals are metallic components that establish the electrical and mechanical connections between the flexible circuit and the mating device.

One of the distinguishing features of FPC connectors is their flat, thin, and flexible shape. This design allows them to be easily integrated into space-constrained electronic devices, where traditional connectors would be impractical or impossible to use. The flexibility of FPC connectors also enables them to withstand repeated bending and flexing, making them ideal for applications that require frequent movement or vibration.

FPC connectors come in various sizes, pitches, and configurations to accommodate different requirements. The pitch refers to the distance between each contact terminal, which determines the density of the connector and the number of conductors it can support. The most common pitches for FPC connectors range from 0.5mm to 2mm.

To ensure a reliable connection, FPC connectors typically feature a locking mechanism or a latching system to securely hold the flexible circuit in place. Some connectors may also have additional features, such as polarization keys or guides, to ensure proper alignment during mating.

In terms of electrical performance, FPC connectors are designed to provide low insertion loss and impedance matching, allowing for efficient signal transmission. They are also capable of handling high-speed data signals and high-frequency signals, making them suitable for applications in industries such as telecommunications, automotive, aerospace, and consumer electronics.

Overall, FPC connectors play a crucial role in the design and functionality of modern electronic devices. Their flexibility, compact size, and reliable performance make them a preferred choice for connecting flexible circuits and enabling the seamless integration of electronic components.

Types of FPC Connectors

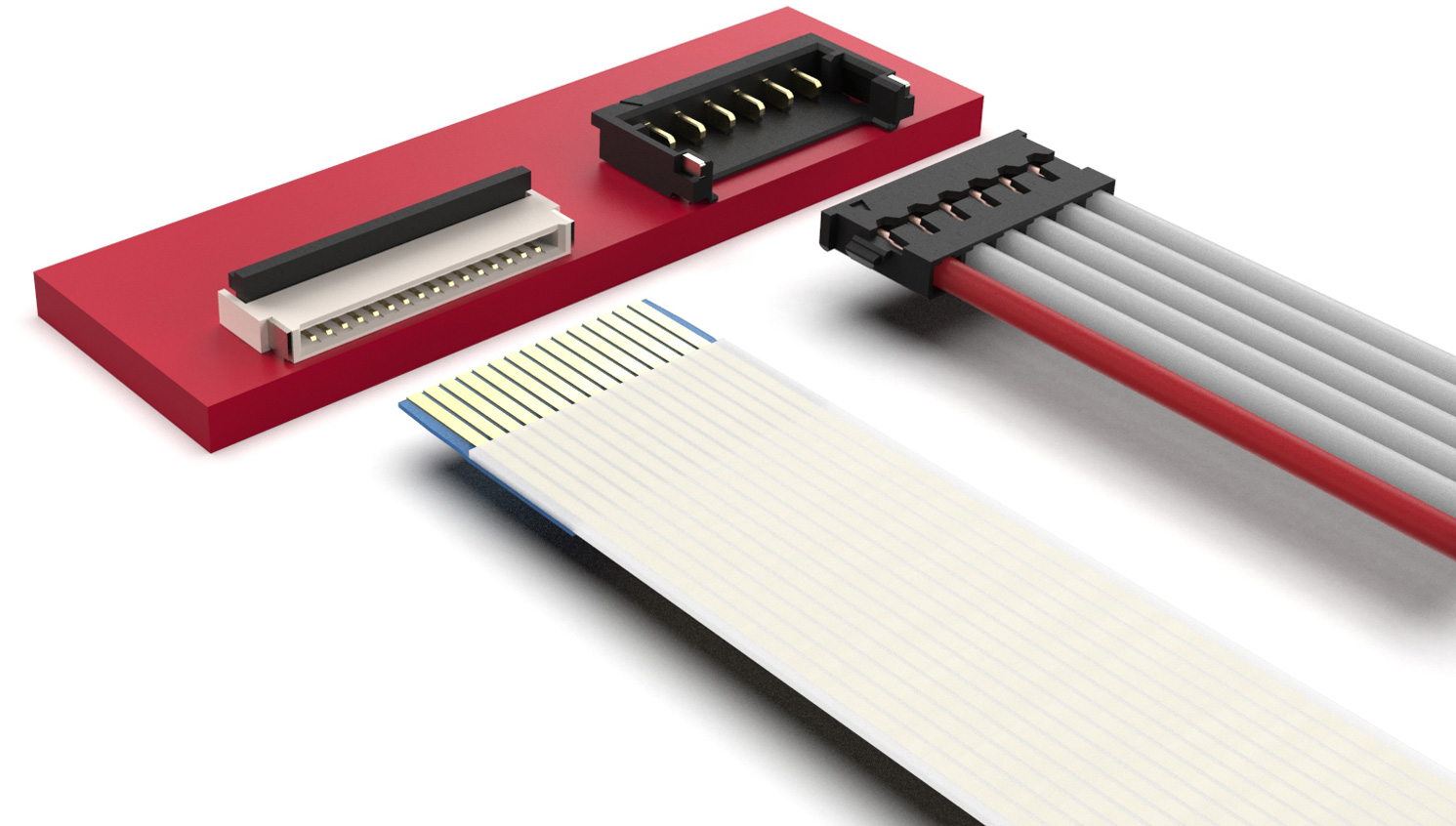

Flexible Printed Circuit (FPC) connectors are essential components in electronic devices, allowing for the secure connection between a flexible PCB and other electronic components. These connectors come in various types, each designed to meet different application requirements. Let’s take a closer look at some common types of FPC connectors:

- Board-to-Board Connectors: Board-to-board FPC connectors provide a reliable connection between two flexible printed circuit boards or between a flexible printed circuit board and a rigid PCB. These connectors are widely used in applications that require the transmission of signals or power between two PCBs.

- Board-to-FPC Connectors: As the name suggests, board-to-FPC connectors are used to connect a flexible printed circuit board to a rigid PCB. These connectors are designed to ensure a secure and stable connection, allowing for the transmission of signals or power between the two boards.

- Cable-to-Board Connectors: Cable-to-board FPC connectors are commonly used in applications that require the connection between a flexible printed circuit and an external cable. These connectors provide a reliable interface, allowing for the transmission of signals or power between the FPC and the cable.

- Wire-to-Board Connectors: Wire-to-board FPC connectors are used to connect a flexible printed circuit to wires. These connectors provide a secure connection, enabling the transmission of signals or power between the FPC and the wires. They are commonly used in applications such as LCD displays and other devices that require flexible interconnects.

- FFC Connectors: Flexible Flat Cable (FFC) connectors are another type of FPC connector that is widely used in the electronics industry. FFC connectors are primarily used to connect a flexible flat cable to a PCB, allowing for the transmission of signals or power.

These are just a few examples of the many types of FPC connectors available in the market. Each type is designed to meet specific application requirements and provide a reliable connection between flexible printed circuits and other components. Knowing the different types can help you choose the right FPC connector for your electronic devices.

Advantages of FPC Connectors

Flexible Printed Circuit (FPC) connectors are widely used in various electronic devices, and they offer several advantages over traditional connectors. These connectors are designed to provide a reliable and flexible connection between components, making them an ideal choice for applications where space and weight are constraints. Let’s explore some of the key advantages of FPC connectors:

- Space-saving design: One of the biggest advantages of FPC connectors is their compact and flexible design. Unlike bulky traditional connectors, FPC connectors are thin and flexible, allowing them to be easily routed and installed in tight spaces. This makes them ideal for compact electronic devices where space is limited.

- Lightweight: FPC connectors are made from lightweight materials such as polyimide or polyester film, which significantly reduces the overall weight of the electronic device. This is especially beneficial for portable devices such as smartphones, tablets, and wearable devices, where weight optimization is crucial.

- Versatile: FPC connectors offer versatility in terms of design and configuration. They can be customized to accommodate specific requirements, such as different pitches, contact layouts, and mounting options. This allows designers to create tailored solutions that meet the unique needs of their applications.

- High-speed data transmission: FPC connectors are capable of transmitting high-speed data signals, making them suitable for applications that require fast and reliable data transfer. The flat surface and short signal path of FPC connectors minimize signal loss and interference, ensuring high-quality signal transmission.

- Excellent reliability: FPC connectors are designed to withstand various environmental conditions, such as temperature variations, vibrations, and shock. Their solderless connection eliminates the risk of cold joints, ensuring a reliable and durable electrical connection. Additionally, FPC connectors have excellent resistance to corrosion, reducing the risk of signal degradation over time.

- Easy installation: FPC connectors are designed for easy installation and removal. They often come with features such as zero insertion force (ZIF) or low insertion force (LIF), allowing for effortless connection and disconnection. This makes them ideal for applications where frequent maintenance or replacement is required.

With their space-saving design, lightweight construction, versatility, high-speed data transmission capabilities, excellent reliability, and easy installation, FPC connectors have become a popular choice for many electronic devices. Whether it’s in consumer electronics, automotive systems, medical devices, or industrial equipment, FPC connectors offer numerous advantages that contribute to the efficient and reliable operation of electronic devices.

Common Applications of FPC Connectors

Flexible Printed Circuit (FPC) connectors have become an indispensable component in various industries due to their flexibility, reliability, and compact design. These connectors find their applications in a wide range of electronic devices and systems. Let’s explore some of the common applications where FPC connectors play a crucial role:

1. Mobile Phones and Tablets: FPC connectors are extensively used in mobile phones and tablets to provide a reliable and flexible connection between the main circuit board and various components such as the display, camera module, and touch screen. Their slim and compact design allows for easy integration into these handheld devices, ensuring seamless performance.

2. Consumer Electronics: FPC connectors are widely employed in various consumer electronic devices such as laptops, cameras, gaming consoles, and smartwatches. They facilitate the interconnection between different internal components, enabling efficient data transmission, power delivery, and signal integrity.

3. Automotive Systems: FPC connectors play a critical role in automotive applications. They are used in infotainment systems, dashboard displays, vehicle navigation systems, and control panels. These connectors are designed to withstand the harsh operating conditions of the automotive environment, including temperature variations, vibrations, and electromagnetic interference.

4. Medical Devices: FPC connectors find extensive use in medical devices and equipment, where space constraints and reliability are of utmost importance. They are employed in ultrasound machines, patient monitoring systems, medical imaging devices, and surgical equipment, providing a robust and flexible connection for critical data transmission and control signals.

5. Industrial Equipment: FPC connectors are widely utilized in industrial automation and machinery. They are found in robotics, control systems, sensors, and communication equipment. The flexible nature of FPC connectors allows for easy routing and installation in complex industrial environments, ensuring reliable data transfer and system performance.

6. LED Lighting: FPC connectors are used in LED lighting applications, including LED strips, backlighting modules, and LED displays. These connectors enable easy interconnection between the LED modules, providing flexibility and convenience during installation and maintenance.

7. Wearable Devices: FPC connectors play a vital role in wearable devices such as fitness trackers, smart glasses, and wearable health monitors. They allow for flexible and reliable connections between different components, ensuring seamless integration and user comfort.

8. Aerospace and Defense: FPC connectors find applications in the aerospace and defense industry where ruggedness, reliability, and miniaturization are critical factors. They are used in avionics systems, military communication devices, satellite systems, and navigation equipment.

9. Internet of Things (IoT) Devices: FPC connectors are essential components in IoT devices, connecting sensors, actuators, and communication modules. These connectors provide the necessary connectivity for data exchange and enable seamless integration of IoT devices into a connected ecosystem.

10. Audio and Video Equipment: FPC connectors are widely employed in audio and video equipment such as televisions, cameras, and audio systems. They enable the transmission of high-quality audio and video signals, ensuring a seamless viewing and listening experience for users.

FPC connectors have revolutionized the field of electronics with their versatility and reliability. Their use in a wide range of applications highlights the importance of these connectors in connecting and powering various electronic systems. As technology continues to advance, the demand for FPC connectors is expected to grow, further expanding their applications in different industries.

Conclusion

In conclusion, FPC connectors play a crucial role in the world of mobile accessories. These flexible and lightweight connectors are vital for connecting various electronic components in smartphones and other portable devices. Their compact size, high data transfer rates, and reliable performance make them an excellent choice for manufacturers and consumers alike.

By understanding the importance of FPC connectors and their functions, you can make informed decisions when buying mobile accessories. Whether you are looking for a new phone case, screen protector, or any other accessory, knowing about FPC connectors will help you choose the right product that is compatible with your device.

Moreover, with the continuous advancements in technology, it is essential to stay updated with the latest trends and developments in mobile accessories. As new features and innovations are introduced, FPC connectors will likely evolve to meet the demands of the industry.

Overall, FPC connectors are a crucial component that enables the seamless functioning of mobile accessories. Their flexibility, durability, and high-performance capabilities make them an indispensable part of the mobile industry, ensuring a seamless user experience for consumers.

FAQs

Q: What is an FPC connector?

An FPC connector, also known as a Flexible Printed Circuit connector, is a type of electrical connector specifically designed for connecting flexible printed circuit (FPC) cables. These connectors are used in a wide range of electronic devices, particularly in the mobile phone industry, where space-saving and flexibility are essential.

Q: How does an FPC connector work?

An FPC connector consists of two main parts – the contact area and the locking mechanism. The contact area is where the FPC cable makes contact with the connector, while the locking mechanism secures the cable in place. When the FPC cable is inserted into the connector, it makes a secure electrical connection with the contact area, allowing for the transfer of signals and power between different components of the electronic device.

Q: What are the advantages of using an FPC connector?

There are several advantages of using FPC connectors in mobile phone and other electronic devices. One of the main advantages is their flexibility. FPC connectors allow for the easy installation and removal of FPC cables, making them ideal for devices that require frequent assembly and disassembly. Additionally, FPC connectors are lightweight and compact, which helps to save space and reduce overall device size. They also offer good electrical performance, ensuring reliable signal transmission.

Q: Are FPC connectors compatible with all mobile phones?

FPC connectors come in various types and configurations, and not all connectors are compatible with all mobile phones. Different mobile phone models may require different types of connectors based on their specific design and electrical requirements. To ensure compatibility, it is important to consult the mobile phone’s specifications or seek the guidance of a professional when selecting or replacing an FPC connector.

Q: Can FPC connectors be repaired or replaced?

In most cases, FPC connectors can be repaired or replaced if they become damaged or faulty. However, the repair or replacement process requires specialized tools and technical expertise, especially since delicate FPC cables are involved. It is recommended to seek professional assistance or consult the device manufacturer if you encounter any issues with the FPC connector in your mobile phone or electronic device.