As the world makes a shift towards greener and more sustainable energy sources, electric vehicles (EVs) have gained significant popularity. One of the key components of an EV is the battery, which powers the vehicle and determines its range and performance. But have you ever wondered how much an EV battery costs? In this article, we’ll dive into the world of EV batteries and explore the factors that impact their cost. Whether you’re considering purchasing an electric vehicle or simply curious about the technology behind it, understanding the cost of EV batteries is essential. So, let’s dig in and unravel the mysteries behind the price tags of these crucial components.

Inside This Article

- Factors affecting EV battery costs

- Comparison of lithium-ion and solid-state EV batteries

- Average Cost of EV Batteries

- Strategies to reduce EV battery costs

- Conclusion

- FAQs

Factors affecting EV battery costs

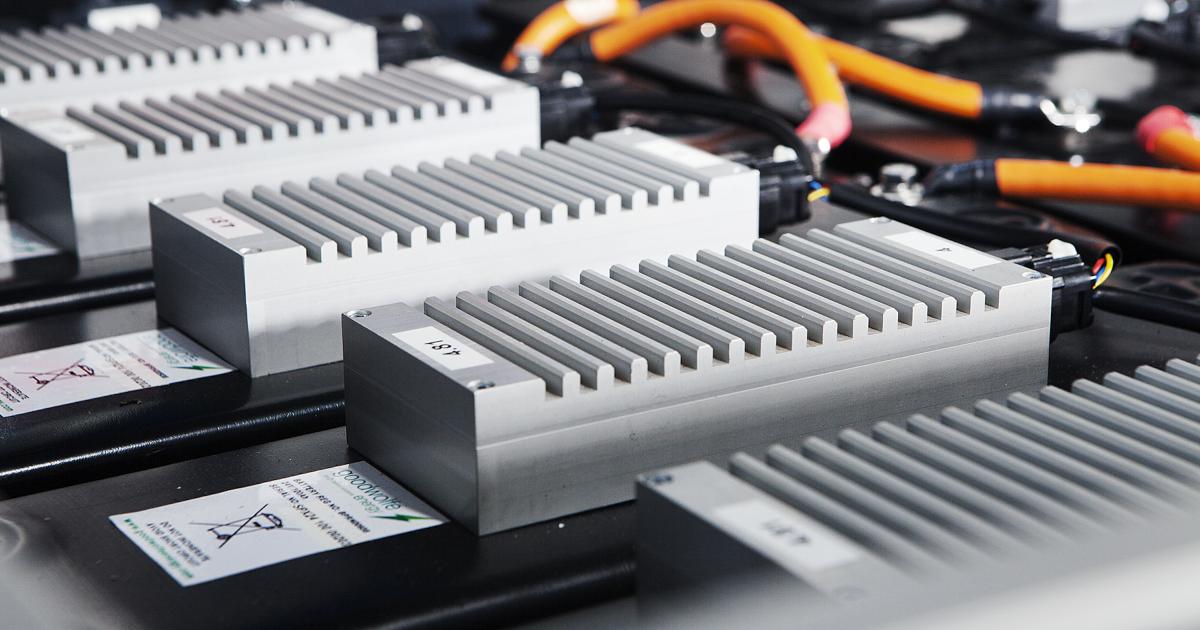

When it comes to electric vehicles (EVs), the cost of the battery plays a significant role in the overall price of the vehicle. Several factors influence the cost of EV batteries, including:

- Battery Chemistry: The chemistry of the battery used in an EV has a direct impact on its cost. Currently, lithium-ion batteries are the most common type used in EVs. However, emerging technologies like solid-state batteries have the potential to reduce costs in the future.

- Battery Capacity: The capacity or energy density of the battery affects its overall cost. Higher capacity batteries have more energy storage, but they also tend to be more expensive to produce.

- Economies of Scale: Like many products, the cost of EV batteries can decrease as production volumes increase. As automakers produce more EVs and battery manufacturers scale up their operations, economies of scale can help drive down costs.

- Raw Materials: The cost of raw materials used in battery production, such as lithium, cobalt, and nickel, can impact the overall cost of EV batteries. Market fluctuations and availability of these materials can influence battery costs.

- Manufacturing Techniques: The manufacturing process for EV batteries can have an impact on costs. Innovations in battery production, such as advanced manufacturing techniques and automation, can help reduce costs and improve efficiency.

- Research and Development: The level of investment in research and development (R&D) for EV batteries can impact their cost. Continued advancements in battery technology through R&D can lead to cost reductions and improved performance.

By understanding the factors that affect EV battery costs, manufacturers and researchers can work towards developing more cost-effective and efficient battery technologies. This, in turn, can help make electric vehicles more accessible to a wider consumer base and accelerate the transition to a greener and sustainable transportation system.

Comparison of lithium-ion and solid-state EV batteries

Lithium-ion batteries have dominated the electric vehicle (EV) market for many years, offering a good balance between energy capacity, weight, and cost. However, a new contender is emerging – solid-state batteries. Let’s take a closer look at the key differences between these two types of EV batteries.

Lithium-ion batteries consist of a liquid or gel electrolyte and lithium-based compounds as the cathode and anode. They have been widely adopted due to their high energy density, long cycle life, and relatively low cost.

On the other hand, solid-state batteries use a solid electrolyte instead of a liquid or gel. This solid-state design offers several advantages. Firstly, solid-state batteries have the potential for higher energy density, which means they can store more energy in a smaller package. This could lead to increased driving range for EVs.

Secondly, solid-state batteries are safer and more stable compared to lithium-ion batteries. The absence of a flammable liquid electrolyte reduces the risk of thermal runaway and the potential for battery fires. This improved safety profile is a significant advantage for EV manufacturers and consumers.

Another advantage of solid-state batteries is their potential for faster charging. The solid electrolyte allows for higher charging currents, enabling quicker recharging times. This could address one of the main concerns of EV owners – the time it takes to recharge their vehicles.

However, there are still challenges to overcome before solid-state batteries can be mass-produced at a competitive cost. Manufacturing processes and materials need to be optimized to achieve the desired performance and cost targets. Additionally, the longevity and durability of solid-state batteries need to be thoroughly tested and validated.

Despite these challenges, solid-state batteries hold great promise for the future of electric vehicles. They offer the potential for increased energy density, improved safety, and faster charging times. As the technology continues to advance, we may see solid-state batteries becoming the new standard for EVs, revolutionizing the industry and making electric transportation even more accessible and convenient for consumers.

Average Cost of EV Batteries

When it comes to electric vehicles (EVs), one of the major factors to consider is the cost of the battery. The battery pack is not only the heart of an EV but also one of the most expensive components. Understanding the average cost of EV batteries can help potential buyers make informed decisions. Let’s take a closer look at the factors that influence battery costs and the current average prices in the market.

1. Battery Technology:

The type of battery technology used in an EV greatly affects its cost. Currently, lithium-ion batteries are the most common choice for EVs due to their high energy density and relatively lower costs compared to other alternatives. However, emerging technologies like solid-state batteries have the potential to revolutionize the industry. While these batteries are more expensive to produce at the moment, ongoing research and development are expected to bring down costs in the future.

2. Battery Size and Range:

The size of the battery pack directly impacts its cost. Larger battery packs not only provide longer driving ranges but also come with a higher price tag. The price of EV batteries is typically quoted in cost per kilowatt-hour (kWh). As battery technology advances, the cost per kWh is gradually decreasing, making electric vehicles more affordable for consumers.

3. Economies of Scale:

As the demand for EVs increases, manufacturers are able to produce batteries in larger quantities. This results in economies of scale, leading to lower production costs. With more automakers entering the EV market and the development of dedicated battery manufacturing plants, the average cost of EV batteries is projected to decline in the coming years.

4. Government Incentives:

In many countries, governments offer incentives and subsidies to promote the adoption of electric vehicles. These incentives can greatly offset the cost of EV batteries, making them more accessible for consumers. It’s important to research and take advantage of these incentives to further reduce the overall cost of owning an electric vehicle.

Currently, the average cost of EV batteries is around $150-$200 per kWh. However, it’s essential to note that prices are continuously changing due to factors such as technological advancements, economies of scale, and market competition. As battery technology improves and production processes become more efficient, the average cost of EV batteries is expected to drop further, making electric vehicles more affordable for a wide range of consumers.

Strategies to reduce EV battery costs

As the demand for electric vehicles (EVs) continues to grow, reducing the cost of EV batteries becomes crucial in making these vehicles more affordable and widely adopted. Manufacturers and researchers are constantly exploring innovative strategies to bring down the cost of EV batteries without compromising their performance and longevity. Here are some strategies that are being pursued to achieve this goal:

1. Advancements in battery technology: One of the most effective ways to reduce EV battery costs is through advancements in battery technology. This includes improving the energy density of batteries, enhancing their charging and discharging capabilities, and increasing their lifespan. By developing batteries with higher energy density, automakers can reduce the number of cells required, leading to cost savings. Research is also focused on developing new materials and manufacturing techniques to make batteries more efficient and cost-effective.

2. Economies of scale: As the production volume of EV batteries increases, economies of scale come into play. With higher production volumes, manufacturers can benefit from lower component costs, streamlined manufacturing processes, and improved supply chain management. This helps in reducing the overall cost per kilowatt-hour (kWh) of the battery pack. As the demand for EVs continues to rise, economies of scale will play a significant role in driving down battery costs.

3. Recycling and second-life applications: Another strategy to reduce EV battery costs is by implementing robust recycling programs and exploring second-life applications. After reaching the end of their life in electric vehicles, batteries can still retain a significant amount of their capacity, making them suitable for second-life applications like energy storage systems. By reusing and repurposing these batteries, their cost can be effectively spread out over a longer lifespan, reducing the overall cost of ownership for EV owners.

4. Improvements in manufacturing: Continuous improvements in manufacturing processes can lead to cost reductions in EV battery production. Embracing automation, implementing lean manufacturing principles, and optimizing supply chain logistics can help in streamlining the production process, reducing material waste, and minimizing labor costs. Manufacturers are also investing in research and development to find more efficient ways to assemble battery packs, which can contribute to cost savings.

5. Government support and incentives: Government support and incentives play a crucial role in reducing EV battery costs. Governments can provide financial assistance, tax incentives, and grants to manufacturers and researchers working on battery technology. These initiatives can help accelerate research and development activities, encourage mass production, and drive down costs through subsidies or grants provided to consumers purchasing EVs.

6. Collaboration and partnerships: Collaboration between automakers, battery manufacturers, and research institutions can lead to shared resources, knowledge exchange, and cost savings. By pooling together their expertise, companies can jointly work on developing breakthrough technologies and finding cost-effective solutions. Collaboration can also help in standardizing battery specifications and manufacturing processes, further reducing costs through economies of scale.

By implementing these strategies, the cost of EV batteries can be significantly reduced, making electric vehicles more accessible to a wider range of consumers. As technology continues to advance and economies of scale come into play, the future of EV batteries looks promising, with the potential for even more affordable and efficient solutions.

Conclusion

In conclusion, the cost of EV batteries is a significant factor to consider when purchasing an electric vehicle. While the upfront price of an EV battery may seem high, it is important to understand the long-term benefits and savings it offers. The cost of EV batteries has been steadily decreasing over the years, making electric vehicles more accessible to a wider range of consumers. Additionally, as technology advances and economies of scale improve, it is expected that the cost of EV batteries will continue to decrease. Furthermore, government incentives and subsidies can further offset the purchase price of an electric vehicle. Ultimately, the cost of an EV battery is an investment in a cleaner and more sustainable future, with the potential for significant savings on fuel and maintenance costs in the long run.

FAQs

1. What is an EV battery?

An EV battery, also known as an electric vehicle battery, is a rechargeable device that stores electrical energy to power an electric vehicle. It is one of the most important components of an electric vehicle, providing the energy needed for the vehicle to run.

2. How much does an EV battery cost?

The cost of an EV battery can vary depending on several factors, including the brand, capacity, and technology used in the battery. On average, the cost of an EV battery ranges from $5,000 to $20,000. However, the prices have been decreasing over the years due to advancements in technology and increased production.

3. How long does an EV battery last?

The lifespan of an EV battery varies depending on various factors, such as usage, temperature, and maintenance. Generally, most EV batteries are designed to last between 8 to 15 years or have a lifespan of around 100,000 to 200,000 miles. However, advancements in battery technology are constantly improving battery life and durability.

4. Can I replace an EV battery?

Yes, it is possible to replace an EV battery when it reaches the end of its lifespan or if it becomes faulty. However, the cost of replacing an EV battery can be significant, and it is recommended to consult with a certified technician or the vehicle manufacturer for the best course of action.

5. Are there any government incentives for EV batteries?

Yes, many governments around the world offer incentives and subsidies to promote the adoption of electric vehicles, including EV batteries. These incentives can include tax credits, rebates, grants, and subsidies, which can help offset the cost of purchasing and installing an EV battery.