Welcome to our comprehensive guide on how to use a butt connector. Butt connectors are a type of electrical connector commonly used in automotive and electrical wiring projects. Whether you’re a professional electrician or a DIY enthusiast, being able to properly use a butt connector is essential for creating secure and reliable electrical connections. In this article, we will walk you through the step-by-step process of using a butt connector, explain its benefits, and provide some tips and tricks to ensure a successful installation. So, whether you’re working on your car’s wiring or tackling a home improvement project, read on to discover all you need to know about using a butt connector.

Inside This Article

- What is a Butt Connector?

- Necessary Tools and Materials: List of Tools and Materials Required for Using a Butt Connector

- Steps to Use a Butt Connector- Step-by-step instructions on how to properly use a butt connector

- Tips and Precautions – Important tips and precautions to keep in mind when using a butt connector

- Conclusion

- FAQs

What is a Butt Connector?

A butt connector is an electrical connector that is commonly used in the automotive and electrical industries. It is a small cylindrical tube with a metal barrel at each end. The purpose of a butt connector is to create a secure and durable connection between two wires or cables.

The metal barrels of the butt connector are typically made of copper or brass, which makes them highly conductive and resistant to corrosion. The tube or body of the connector is usually made of a durable plastic material, such as nylon or polypropylene.

Butt connectors come in various sizes and are available in both insulated and non-insulated versions. The insulation on the connector helps to protect the wires from moisture, dust, and other environmental factors.

The main function of a butt connector is to join two or more wires together, creating a continuous electrical circuit. It is commonly used for tasks such as wire splicing, repairing damaged wires, or extending wire lengths. Butt connectors provide a secure and reliable connection that ensures proper electrical conductivity, which is crucial for the efficient operation of electrical systems.

Overall, the primary purpose of a butt connector is to simplify and streamline the process of connecting wires, providing a convenient and effective solution for electrical installations and repairs.

Necessary Tools and Materials: List of Tools and Materials Required for Using a Butt Connector

When it comes to using a butt connector, having the right tools and materials is essential for a successful connection. Whether you’re repairing or installing electrical wiring, following is a list of the necessary tools and materials you’ll need:

- Wire Strippers: A pair of wire strippers is crucial for removing insulation from the ends of the wires you’ll be connecting. Choose wire strippers that are compatible with the gauge of wires you’re working with.

- Butt Connectors: Of course, you’ll need butt connectors themselves. These small cylindrical connectors are designed to join two or more wires together securely. They come in a variety of sizes to accommodate different wire gauges.

- Crimping Tool: To ensure a reliable connection, you’ll need a good crimping tool. This tool is used to compress the metal sleeve of the butt connector around the wires, creating a secure and durable bond.

- Wire Cutters: Wire cutters or a pair of sharp scissors will come in handy for trimming the excess wire after making the connection. It’s important to cut the wire flush with the butt connector to ensure a neat and tidy installation.

- Heat Shrink Tubing: Although not essential, using heat shrink tubing can provide added protection and insulation to the butt connector. This tubing shrinks when heat is applied, creating a tight seal around the connection.

- Heat Gun or Lighter: If you choose to use heat shrink tubing, you’ll need a heat gun or a lighter to apply heat and shrink the tubing. Be careful when using a lighter and ensure proper ventilation to avoid accidents.

- Electrical Tape: While not always necessary, electrical tape can be used to further secure the connection and provide additional insulation. Wrapping a layer of electrical tape around the butt connector can help protect it from moisture and other external elements.

- Wire Labels and Marker: If you’re working with multiple wires, it’s a good idea to label them to avoid confusion. Wire labels and a marker will help you identify the wires and ensure that you make the correct connections.

By having these essential tools and materials on hand, you’ll be well-prepared to use a butt connector efficiently and effectively. It’s always better to have everything you need before beginning the task to ensure a smooth and hassle-free experience.

Steps to Use a Butt Connector- Step-by-step instructions on how to properly use a butt connector

Using a butt connector is a simple and effective way to join two electrical wires together. Whether you are repairing a wire harness or installing a new connection, following these step-by-step instructions will ensure a secure and reliable electrical connection. So, let’s get started!

- Gather the necessary tools and materials: Before you begin, make sure you have all the required items. This includes wire strippers, crimping pliers, heat shrink tubing (if desired), and the wires you intend to connect.

- Prepare the wires: Use the wire strippers to carefully remove a small section of insulation from each wire. Make sure to expose enough bare wire for a secure connection.

- Insert the wires into the butt connector: Take one of the prepared wires and insert it into one end of the butt connector. Repeat the same process with the other wire, inserting it into the opposite end of the connector.

- Crimp the connector: Using the crimping pliers, firmly squeeze the butt connector around the wires. This will create a tight and secure connection between the wires.

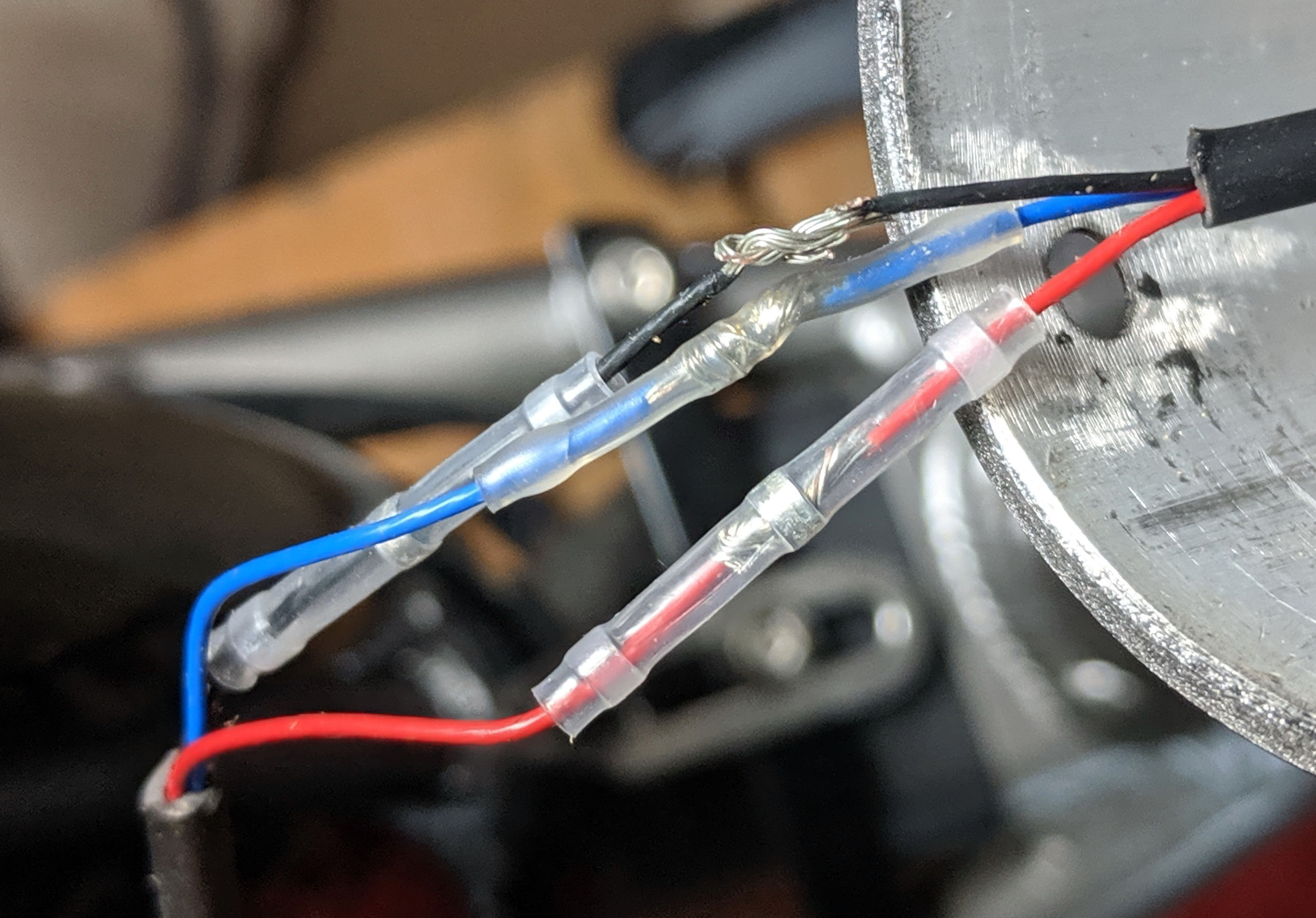

- Optional: Apply heat shrink tubing: If desired, you can slide a piece of heat shrink tubing over the connection. Use a heat source, such as a heat gun or a lighter, to shrink the tubing and provide added protection and insulation to the connection.

- Test the connection: Once the butt connector is securely crimped and any heat shrink tubing has been applied, test the connection to ensure it is functioning properly. Use a multimeter or perform a visual inspection to confirm the integrity of the connection.

- Tidy up the wiring: If necessary, secure the wires and the butt connector using zip ties or electrical tape. This will help prevent any strain on the connection and keep the wiring neat and organized.

Congratulations! You have successfully used a butt connector to join two electrical wires together. Following these steps will ensure a strong and reliable connection that will withstand the test of time. Remember to always follow safety precautions when working with electrical wiring and consult a professional if you are unsure or uncomfortable performing these tasks.

Tips and Precautions – Important tips and precautions to keep in mind when using a butt connector

When it comes to using a butt connector for your electrical or automotive wiring needs, there are some important tips and precautions to keep in mind. Proper usage of a butt connector ensures a secure and reliable electrical connection. Here are some tips to follow:

1. Choose the Right Size: Butt connectors come in various sizes to accommodate different wire gauges. It’s crucial to select the correct size that matches the wire you’re working with. Using an improper size can lead to a loose or unreliable connection. Refer to the wire gauge chart to determine the appropriate butt connector size.

2. Strip the Wire Correctly: Before inserting the wire into the butt connector, it’s essential to strip the insulation correctly. Use a wire stripper to remove the appropriate length of insulation from the wire end. Avoid stripping too much or too little, as it can affect the integrity of the connection.

3. Crimp Properly: The crimping process ensures a tight and secure connection between the wire and the butt connector. Use a high-quality crimping tool designed for butt connectors. Position the wire into the connector barrel and apply firm pressure to crimp it. Verify that the crimped connection is secure without any exposed wire or insulation.

4. Use Heat Shrink Tubing: To provide added protection and insulation, consider using heat shrink tubing. Before crimping the butt connector, slide a suitable length of heat shrink tubing over the wire. Once the connection is crimped, use a heat gun to shrink the tubing, creating a sealed and waterproof connection.

5. Secure the Connection: After crimping the butt connector and shrinking the tubing (if applicable), ensure the connection is firmly secured. Gently tug on the wire to check for any signs of movement or looseness. If it feels loose, repeat the crimping process or consider using a different size butt connector.

6. Protect Against Moisture and Corrosion: Butt connectors can be exposed to moisture, which can lead to corrosion and electrical issues. To combat this, apply a layer of electrical tape or use a waterproof sealant over the connection area, providing an extra layer of protection against water and corrosion.

7. Inspect and Test: Once you’ve completed the butt connector installation, inspect the connections for any signs of damage or loose wires. Additionally, test the connection using a multimeter or a circuit tester to ensure it is functioning properly.

8. Seek Professional Help if Needed: If you are unsure or uncomfortable with using a butt connector, it is always best to seek the assistance of a professional electrician or automotive technician. They have the experience and knowledge to ensure a safe and reliable connection.

By following these tips and precautions, you can use a butt connector effectively and confidently, ensuring a secure and reliable electrical connection for your wiring needs.

Conclusion

Using a butt connector to connect wires is a simple and efficient way to ensure a secure electrical connection. With the right tools and technique, you can create a strong and reliable joint that will withstand the test of time. Whether you are working on a DIY project or a professional electrician, understanding how to use a butt connector is essential.

Remember to always select the appropriate size of butt connector for your wires and use crimping or soldering methods to secure the connection. Make sure to follow proper safety precautions and double-check your work to avoid any potential hazards or defects.

By mastering the art of using a butt connector, you can confidently tackle any wiring project with ease. So, go ahead and get those wires connected with a reliable butt connector!

FAQs

1. What is a butt connector?

A butt connector is a type of electrical connector used to join or splice two or more wires together. It is designed in a cylindrical shape with a hollow chamber in the middle. Butt connectors are commonly used in automotive and electrical applications to provide a secure and reliable connection between wires.

2. How do I use a butt connector?

Using a butt connector is simple and straightforward. Start by stripping the insulation off the ends of the wires you wish to connect. Insert each stripped wire end into one end of the butt connector. Hold the connector securely in place and crimp the metal sleeve around the wires using a crimping tool or pliers. Ensure a tight and secure connection by tugging on the wires gently.

3. Are butt connectors waterproof?

Standard butt connectors are not waterproof. However, there are special types of butt connectors, known as heat shrink butt connectors, that provide a waterproof seal. Heat shrink butt connectors have an adhesive lining that melts and creates a waterproof seal when heated. These connectors are ideal for outdoor or marine applications where moisture and water exposure are a concern.

4. Can I reuse a butt connector?

Butt connectors are not designed for reusability. Once a butt connector is crimped and the wires are inserted, it is intended for a permanent connection. Attempting to remove the wires or reuse the connector may cause damage or result in an unreliable connection. It is recommended to use a new butt connector whenever making a connection or splice.

5. What size butt connector should I use?

The size of the butt connector you should use depends on the gauge or thickness of the wires you are connecting. Butt connectors come in various sizes to accommodate different wire gauges. It is important to choose a butt connector that matches the wire gauge to ensure a proper and secure connection. Using a connector that is too small may result in a weak connection, while using one that is too large may lead to a loose connection or poor conductivity.