Are you looking for a reliable and efficient way to connect or repair electrical wires? Look no further than the split bolt connector! Whether you’re an electrician or a DIY enthusiast, it’s crucial to understand how to use this essential electrical accessory properly.

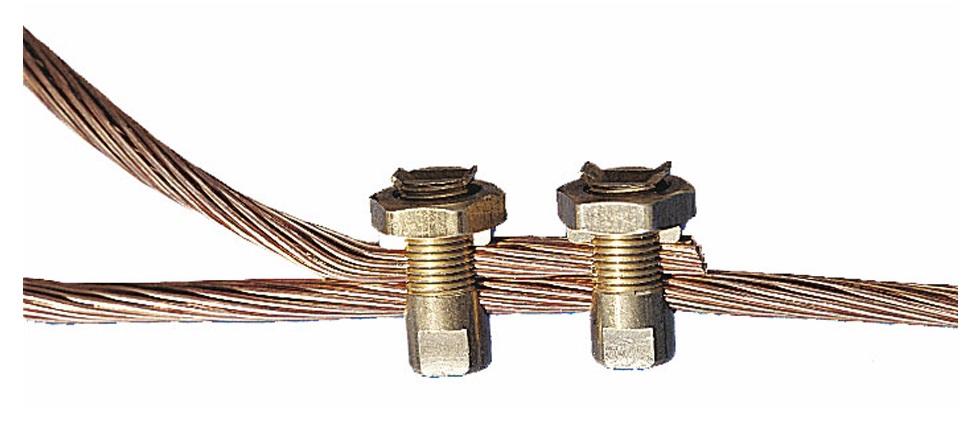

A split bolt connector, also known as a line tap or splice connector, is a type of electrical coupling device used for joining two or more wires together. It provides a secure and conductive connection that allows for easy installation and maintenance of electrical systems.

In this article, we will guide you through the step-by-step process of using a split bolt connector, highlight its benefits, and provide some helpful tips for a successful connection. So, let’s dive in and discover how this versatile accessory can simplify your electrical projects!

Inside This Article

- How To Use a Split Bolt Connector

- Safety Precautions

- Step-by-Step Guide to Using a Split Bolt Connector

- Troubleshooting Tips

- Conclusion

- FAQs

How To Use a Split Bolt Connector

A split bolt connector, also known as a wire connector or a line splice, is a versatile and essential component used in electrical installations. It allows for secure and efficient connections between two or more electrical conductors.

Whether you are a seasoned electrician or a DIY enthusiast, learning how to use a split bolt connector can come in handy for a wide range of electrical projects. In this article, we will guide you through the step-by-step process of using a split bolt connector.

Safety Precautions

Before you begin working with electrical connections, it is crucial to prioritize safety. Here are a few important safety precautions to keep in mind:

- Make sure to turn off the power supply to the circuit you will be working on. This helps prevent electrical shock and other accidents.

- Wear appropriate personal protective equipment (PPE), including safety gloves and goggles, to protect yourself from any potential hazards.

- Inspect the split bolt connector for any damage or defects before use. Do not use a connector that shows signs of corrosion or wear.

Step-by-Step Guide to Using a Split Bolt Connector

Now that you are familiar with the necessary safety precautions, let’s dive into the step-by-step process of using a split bolt connector:

- Start by stripping the insulation off the ends of the wire conductors you wish to connect. Use a wire stripper to remove the appropriate length of insulation, leaving a clean, bare wire.

- Hold one wire conductor in each hand and align the ends together, ensuring that they overlap by at least one inch.

- Take the split bolt connector and position it over the overlapped wire ends. Make sure the connector is large enough to accommodate the wire gauge and the number of conductors being connected.

- Apply even pressure and twist the split bolt connector clockwise onto the wire ends. Keep twisting until the connector is securely fastened and the wires are tightly held together.

- Inspect the connection to ensure that there are no exposed wires or loose connections. If needed, use electrical tape to wrap the connection for added protection.

- Repeat the above steps for any additional wire conductors that need to be connected using the split bolt connector.

- Once all the connections have been made, use a voltage tester to confirm that the circuit is still switched off before turning the power supply back on.

By following these steps, you can effectively use a split bolt connector to create secure and reliable electrical connections in your projects.

Troubleshooting Tips

If you encounter any issues with the split bolt connector connection, here are a few troubleshooting tips to help you resolve common problems:

- Check for proper strip length: Ensure that the insulation is stripped off the wire ends at the correct length. Too much or too little stripped insulation can affect the quality of the connection.

- Inspect the connector size: Confirm that you are using the right size split bolt connector for the wire gauge and the number of conductors being connected. An undersized or oversized connector may result in poor performance.

- Ensure tightness: Double-check that the split bolt connector is securely tightened onto the wire ends. A loose connection can create resistance and lead to overheating or power loss.

- Verify insulation: Make sure the insulation of the connecting wires is intact and undamaged. Exposed wires can cause short circuits or electrical shocks.

By following these troubleshooting tips, you can overcome common challenges and ensure the successful use of a split bolt connector in your electrical projects.

Safety Precautions

When using a split bolt connector, it is essential to follow some safety precautions to prevent any accidents or injuries. These precautions will help ensure that the installation process is conducted safely and minimize any potential risks. Here are some key safety precautions to keep in mind:

- Turn off the power: Before working with a split bolt connector, make sure to turn off the power to the electrical circuit. This will help prevent electric shocks and other electrical hazards. It is important to double-check that the power is completely shut off before proceeding with the installation.

- Wear protective gear: Always wear appropriate safety equipment, such as insulated gloves, safety glasses, and a face mask. Insulated gloves will help protect you from electric shocks, while safety glasses and a face mask will protect your eyes and respiratory system from any debris or particles that may be released during the installation process.

- Inspect the connector: Before using a split bolt connector, carefully inspect it for any signs of damage or wear. Check for issues such as cracks, corrosion, or frayed wires. If you notice any damage, do not use the connector and replace it with a new one. Using a damaged connector can compromise the integrity of the electrical connection and lead to potential hazards.

- Properly size the wire: It is crucial to ensure that the wire you are connecting with the split bolt connector is properly sized. Using wires that are too thin or too thick can result in poor connections, overheating, or even electrical fires. Refer to the manufacturer’s guidelines or consult an electrician to determine the appropriate wire size for your specific application.

- Secure the connector: Make sure that the split bolt connector is securely tightened to maintain a reliable electrical connection. Use a properly sized wrench or pliers to tighten the connector, ensuring that it is snug but not overly tightened. Over-tightening can damage the connector or the wires, leading to potential issues down the line.

- Follow local electrical codes: Familiarize yourself with the electrical codes and regulations in your area. Ensure that you adhere to the guidelines and requirements when installing the split bolt connector. Following local electrical codes will help you meet safety standards and prevent any potential violations.

- Seek professional assistance if needed: If you are not experienced or confident in working with electrical connections, it is best to seek the help of a qualified electrician. They have the knowledge and expertise to ensure that the split bolt connector is installed correctly and safely.

By following these safety precautions, you can minimize the risks associated with using a split bolt connector and ensure a safe and successful installation process.

Step-by-Step Guide to Using a Split Bolt Connector

When it comes to electrical connections, a split bolt connector is a reliable and versatile solution. Split bolt connectors are commonly used in various applications, such as joining electrical wires, grounding systems, and connecting overhead power lines. If you’re looking to use a split bolt connector for your electrical project, follow these easy step-by-step instructions to ensure a secure and effective connection:

- Gather Your Materials: Before you begin, make sure you have all the necessary materials handy. This includes the split bolt connector, wires to be connected, a wire brush, electrical tape, and a torque wrench.

- Prepare the Wires: Start by stripping the insulation off the ends of the wires that you want to connect. Use a wire stripper to carefully remove the protective coating, exposing the conductive metal.

- Clean the Wires: Once the wires are stripped, use a wire brush to clean the exposed metal surfaces. This helps remove any dirt, corrosion, or oxidation that may hinder a proper connection.

- Insert the Wires: Take the split bolt connector and loosen the set screws. Insert the ends of the wires into the connector. Ensure that each wire is placed snugly into the connector, with no exposed strands.

- Tighten the Set Screws: Using a torque wrench, tighten the set screws on the split bolt connector. It is important to follow the manufacturer’s instructions for the recommended torque value to avoid damaging the wires or the connector.

- Inspect the Connection: After tightening the set screws, visually inspect the connection to ensure that the wires are securely held in place. There should be no visible gaps or movement between the wires and the connector.

- Secure the Connection: To provide added protection and insulation, wrap the connection with electrical tape. Start a few inches away from the split bolt connector and wrap the tape tightly around the connection, overlapping the layers as you go.

- Test the Connection: Once you have completed the connection, it is essential to test its effectiveness. Use a multimeter or a circuit tester to check if there is continuity between the connected wires. This will ensure that the connection is secure and electrically sound.

By following these step-by-step instructions, you can confidently use a split bolt connector for your electrical connections. Remember to always prioritize safety, adhere to local electrical codes, and consult a professional if you have any doubts or concerns.

Troubleshooting Tips

Even with the proper installation of a split bolt connector, there may be instances where issues arise. In such cases, it’s important to troubleshoot the problem to ensure the connection is secure and functioning correctly. Here are some troubleshooting tips to help you resolve any potential issues:

- Inspect the Connection: Start by visually inspecting the split bolt connection. Check for any signs of damage or loose connections. Ensure that the wires are properly aligned and securely fastened within the connector.

- Tighten the Bolts: If you notice any loose bolts, use a socket wrench to tighten them. Be careful not to overtighten, as this can damage the wires or the connector. Use a torque wrench if necessary to ensure the proper level of tightness.

- Clean the Connection: Over time, dirt, grease, or other contaminants may accumulate on the split bolt connector. This can interfere with the conductivity of the connection. Use a clean cloth or electrical contact cleaner to remove any debris and ensure a clean and secure contact.

- Check for Corrosion: Corrosion can occur on the surface of the split bolt connector, especially in outdoor or high-humidity environments. Inspect the connector for any signs of corrosion, such as a greenish or brownish buildup. Use a wire brush or sandpaper to gently remove the corrosion and restore a clean surface.

- Verify Wire Size Compatibility: Ensure that the wires being connected are properly sized for the split bolt connector. If the wires are too large or too small for the connector, it can result in an unreliable connection. Consult the manufacturer’s guidelines or consult with a professional to ensure proper wire size compatibility.

- Reposition the Connection: Sometimes, the positioning of the wires within the split bolt connector may cause issues. Try repositioning the wires to ensure they are making full contact with the connector. Verify that the wires are properly aligned and seated within the connector before tightening the bolts.

- Consult an Expert: If you’ve exhausted all troubleshooting options and are still experiencing issues with the split bolt connector, it may be best to consult with a professional electrician or technician. They can provide expert guidance and assistance in resolving the problem.

By following these troubleshooting tips, you can overcome common issues that may arise with a split bolt connector. Remember to prioritize safety and always consult with a professional if you are unsure about any aspect of the troubleshooting process.

Conclusion

Using a split bolt connector is an effective way to join electrical wires securely and safely. These connectors provide a strong and reliable connection, ensuring that your electrical system operates efficiently without any loose or exposed wires. By following the steps outlined in this guide and using the proper tools and techniques, you can easily and confidently use a split bolt connector for various applications.

Remember, always prioritize safety when working with electrical connections. Make sure to turn off the power supply before starting any electrical work, and wear appropriate protective gear. If you’re unsure about any aspect of using a split bolt connector, it’s best to consult a professional electrician who can offer expert guidance and assistance.

So, whether you’re making repairs or installations, a split bolt connector is a versatile and reliable solution for joining electrical wires. By mastering the techniques described in this guide, you’ll be able to handle a wide range of electrical projects with confidence and efficiency.

FAQs

1. What is a split bolt connector?

A split bolt connector is a type of electrical connector used to join or splice two or more electrical wires together. It is designed with a bolt that can be tightened to secure the connection, ensuring a reliable and solid electrical connection.

2. Where are split bolt connectors used?

Split bolt connectors are commonly used in various electrical applications, including power distribution systems, electrical panels, grounding systems, and motor connections. They are also used in industrial and commercial settings where a secure and durable electrical connection is required.

3. How do I use a split bolt connector?

To use a split bolt connector, follow these steps:

– Strip approximately 1 inch of insulation from the ends of the wires you want to connect.

– Insert the stripped ends of the wires into the split opening of the connector.

– Ensure that the wires are tightly inserted and properly aligned.

– Using a wrench or pliers, tighten the bolt of the connector until it is snug and securely holds the wires in place.

– Check to make sure the connection is tight and secure.

4. Are split bolt connectors reusable?

Yes, split bolt connectors are generally reusable. However, it is important to inspect the connector before each use and ensure that it is in good condition. If the connector shows signs of damage or wear, it should be replaced with a new one to maintain a safe and reliable electrical connection.

5. Are there any safety considerations when using split bolt connectors?

Yes, safety is always a priority when working with electrical connections. Here are a few safety considerations when using split bolt connectors:

– Make sure the power is turned off before making any electrical connections.

– Use the appropriate gauge and type of wire for the specific application.

– Follow the manufacturer’s instructions and guidelines when using split bolt connectors.

– Inspect the connector and wires for any signs of damage or wear before installation.

– When working with high voltage applications, it is recommended to seek assistance from a trained professional.