An IDC connector, also known as an Insulation Displacement Connector, is a type of connection used in the electronics industry to make efficient and reliable electrical connections. IDC connectors are commonly found in a wide range of devices, including cell phones, where they play a crucial role in connecting various components and accessories.

The IDC connector gets its name from its unique feature of displacing insulation material to make contact with the conductors. This is achieved by squeezing the connector onto the flat conductor cables, which causes the sharp teeth inside the connector to penetrate the insulation and connect with the internal conductors.

With their reliable connections and ease of use, IDC connectors are widely used in mobile accessories such as chargers, earphones, and data cables. They provide a secure and efficient way to transfer power and data between devices, making them an essential component in today’s mobile technology.

Inside This Article

- Overview of IDC Connectors

- Structure and Components of IDC Connectors

- Types of IDC Connectors

- Applications and Uses of IDC Connectors

- Conclusion

- FAQs

Overview of IDC Connectors

IDC connectors, also known as Insulation Displacement Connectors, are widely used in the electronics and telecommunications industries. These connectors provide a reliable and efficient method for terminating and joining wires. The unique feature of IDC connectors is that they allow for easy and secure connection of multiple conductors without the need for soldering or crimping.

With IDC connectors, wires are typically inserted into slots or openings within the connector. The connector contacts have sharp edges or blades that penetrate the insulation of the wire and make direct contact with the conductor. This displacement of insulation allows for a gas-tight electrical connection to be established, ensuring a strong and reliable electrical connection.

One of the key advantages of IDC connectors is their ease of use. They eliminate the need for specialized tools or equipment, making them ideal for both professional and DIY applications. Additionally, IDC connectors offer a quick and efficient method for connecting multiple wires, reducing installation time and effort.

Another advantage of IDC connectors is their versatility. They are available in various configurations, including single row, dual row, and D-sub connectors, to accommodate different wire sizes and pin counts. IDC connectors can be used with a wide range of wire types, including flat ribbon cables and round conductor cables.

Moreover, IDC connectors provide a secure and reliable connection. The displacement of insulation ensures a high contact force between the connector and the conductor, minimizing the risk of connection failure or intermittent contact. This makes IDC connectors suitable for applications with demanding environmental conditions or high vibration levels.

Overall, IDC connectors offer a practical and efficient solution for electrical connections. Their ease of use, versatility, and reliable performance make them a popular choice in various industries, including telecommunications, data centers, automotive, aerospace, and consumer electronics.

Structure and Components of IDC Connectors

Understanding the structure and components of IDC (Insulation Displacement Connector) connectors is essential for anyone working with mobile accessories or in the field of telecommunications. IDC connectors are widely used in the industry due to their ease of installation and reliable performance. Let’s take a closer look at the key elements that make up an IDC connector.

1. Contact Blades: The contact blades are the heart of an IDC connector. These metallic blades have sharp and V-shaped teeth that are designed to pierce through the insulation of the wire when inserted. The teeth make a secure and reliable electrical connection with the conductors inside the wire.

2. Insulation Displacement Slots: IDC connectors have slots specifically designed to accommodate the contact blades. These slots ensure proper alignment of the blades and guide them into the insulation of the wire. The blades penetrate the insulation, making direct contact with the conductors while retaining the integrity of the wire’s insulation.

3. Housing: The housing of an IDC connector holds the contact blades in place. It is usually made of plastic or other non-conductive materials. The housing provides protection and support to the contact blades, ensuring they remain securely positioned and aligned within the connector.

4. Connector Body: The connector body is the outer shell of the IDC connector. Its primary function is to provide mechanical strength and protection to the internal components. The connector body is also designed to allow for easy insertion and removal of the connector into a mating receptacle.

5. Retention Mechanism: Some IDC connectors come with a retention mechanism to provide additional security and prevent accidental disconnection. This mechanism may include latches, clips, or locking tabs that ensure a tight and reliable connection.

6. Strain Relief: IDC connectors often incorporate strain relief features to prevent excessive stress on the wires and the connector itself. These features can include cable clamps, flex-reliefs, or strain relief boots, which help in maintaining the structural integrity and longevity of the connector.

7. Color Coding: In many instances, IDC connectors are color-coded to facilitate easy identification and installation. Different colors may represent specific wire gauges or connector types, simplifying the process of selecting the appropriate connector for a particular application.

Understanding the structure and components of IDC connectors allows technicians and professionals to make informed decisions when selecting, installing, and troubleshooting these connectors. With their reliable performance, ease of use, and efficiency, IDC connectors continue to play a crucial role in the world of mobile accessories and telecommunications.

Types of IDC Connectors

When it comes to IDC (Insulation Displacement Connector) connectors, there are several types available on the market. Each type serves a specific purpose and is designed to meet different requirements. Let’s take a look at some of the most common types of IDC connectors:

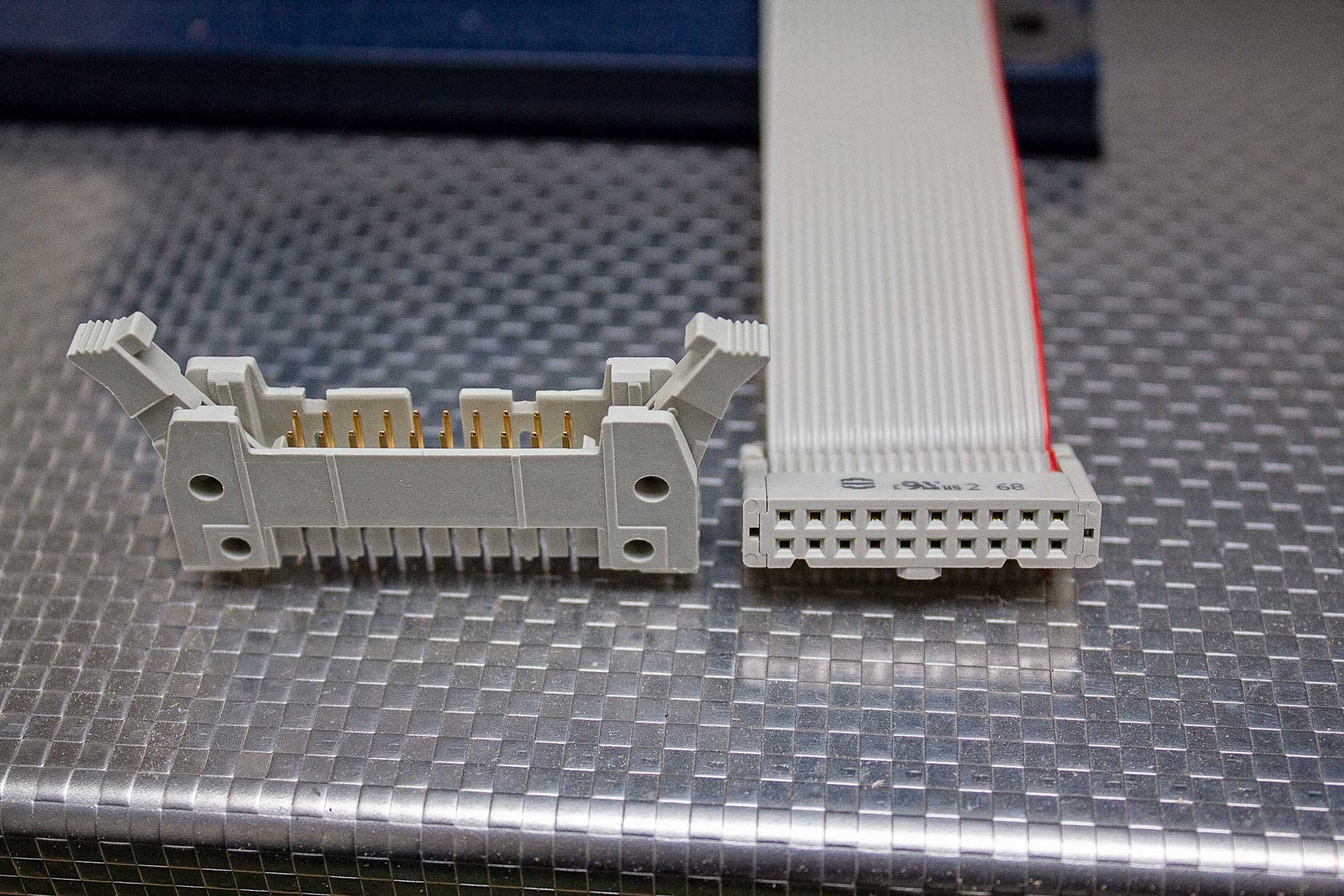

1. Ribbon Cable IDC Connectors: This type of IDC connector is specifically designed for ribbon cables. It features multiple contacts arranged in a row and is capable of connecting a large number of wires simultaneously. Ribbon cable IDC connectors are commonly used in applications such as internal computer connections, telecommunications equipment, and consumer electronics.

2. D-sub IDC Connectors: Also known as D-subminiature connectors, D-sub IDC connectors are commonly used in computer and data communication applications. They are named after their “D” shaped housing and feature a fixed number of pins or sockets, typically in multiples of 9 or 15. D-sub IDC connectors are widely used for serial and parallel data transfer, as well as in networking and industrial applications.

3. FFC/FPC IDC Connectors: FFC (Flexible Flat Cable) and FPC (Flexible Printed Circuit) IDC connectors are designed for connecting flexible circuits or flat cables. These connectors feature a locking mechanism that secures the cable or circuit in place, providing reliable and consistent electrical connections. FFC/FPC IDC connectors are commonly found in applications such as laptops, smartphones, tablets, and other portable electronic devices.

4. Box Header IDC Connectors: Box header IDC connectors, also known as shrouded box headers, are commonly used in PCB (Printed Circuit Board) applications. They are designed to provide a reliable and secure connection between a PCB and another device. Box header IDC connectors consist of a series of pins or sockets enclosed in a plastic housing, providing protection against accidental contact or damage. These connectors are widely used in computer peripherals, industrial equipment, and automotive applications.

5. Modular IDC Connectors: Modular IDC connectors are widely used for networking applications, such as Ethernet and telephone connections. They feature a modular jack design, allowing quick and easy installation and removal. Modular IDC connectors are commonly found in residential and commercial buildings, as well as in data centers and telecommunications infrastructure.

6. Power IDC Connectors: Power IDC connectors are specifically designed for high-current or high-power applications. They are capable of handling larger wire gauges and higher current ratings compared to other IDC connectors. Power IDC connectors are commonly used in power supplies, industrial equipment, automotive applications, and other high-power applications.

These are just a few examples of the various types of IDC connectors available. The right choice of IDC connector for a specific application depends on factors such as the number of wires to be connected, the type of cable or circuit to be used, and the operating conditions. By understanding the different types of IDC connectors, you can select the most suitable option for your specific needs.

Applications and Uses of IDC Connectors

IDC connectors, or insulation displacement connectors, are widely used in various industries and applications where secure and reliable electrical connections are required. These versatile connectors offer numerous benefits and are used in a wide range of devices and systems. Let’s explore some of the common applications and uses of IDC connectors:

1. Telecommunications: IDC connectors are extensively used in the telecommunications industry for connecting cables to equipment, such as modems, routers, and switches. They provide a reliable connection for data and voice transmission, ensuring seamless communication.

2. Computer Hardware: IDC connectors are commonly found in computer hardware components, including hard drives, floppy drives, and optical drives. These connectors establish a secure and efficient connection between the drives and the motherboard, facilitating data transfer and communication between different computer components.

3. Automotive Industry: IDC connectors play a crucial role in the automotive industry, where they are used for various applications, such as connecting wires for sensors, switches, and control modules. They provide a reliable electrical connection that can withstand harsh environments, vibrations, and temperature fluctuations.

4. Consumer Electronics: IDC connectors are used in numerous consumer electronic devices, including TVs, gaming consoles, printers, and audio equipment. These connectors ensure reliable connectivity between different components and enable seamless operation of the devices.

5. Industrial Control Systems: IDC connectors are extensively used in industrial control systems, where they connect various equipment and devices. These connectors offer a secure and efficient connection, making them suitable for automation systems, factory machinery, and process control systems.

6. Medical Devices: IDC connectors are also utilized in the medical industry for various applications, including monitoring equipment, diagnostic devices, and patient care systems. These connectors meet stringent safety and reliability standards, ensuring accurate and consistent performance in medical settings.

7. Aerospace and Defense: IDC connectors are employed in aerospace and defense applications, where they provide secure and high-performance connections for critical systems. They are used in avionics, satellite communication systems, military vehicles, and other defense applications.

8. Home Automation: With the increasing popularity of home automation systems, IDC connectors are used to connect smart devices, such as smart lights, thermostats, and security systems. These connectors enable seamless communication between different devices, allowing homeowners to control and monitor their homes remotely.

These are just a few examples of the wide-ranging applications and uses of IDC connectors. With their versatility, reliability, and ease of installation, IDC connectors have become an integral part of various industries where secure and efficient electrical connections are paramount.

Conclusion

In conclusion, the IDC connector is a vital component in many electronic devices. Its compact size, ease of use, and reliable performance make it a popular choice for connecting various components within a device or between devices. Whether it is used in cell phones, computers, or other electronic devices, the IDC connector plays a crucial role in ensuring seamless connectivity and efficient operation.

With its simple yet effective design, the IDC connector has revolutionized the way we connect and assemble electronic devices. Its ability to securely hold and transmit signals make it an essential part of the ever-evolving technology landscape.

As technology continues to advance and devices become more compact, the importance of IDC connectors will only grow. Manufacturers and consumers alike can rely on these connectors to provide a robust and reliable connection, ensuring the seamless operation of their electronic devices.

Whether you’re a tech enthusiast, a professional in the industry, or simply curious about the inner workings of your electronic devices, understanding the IDC connector can deepen your appreciation for the intricate engineering that goes into making our devices function flawlessly.

FAQs

1. What is an IDC connector?

An IDC (Insulation Displacement Connector) connector is a type of electrical connector that is used to terminate electrical wires or cables. It is designed to make a reliable and secure connection without the need for soldering or crimping. The IDC connector features sharp, wedge-shaped contacts that pierce through the insulation of the wire, making contact with the conductive core. This allows for quick and easy installation, making it a popular choice for a variety of applications, including computer and telecommunications equipment.

2. How does an IDC connector work?

The IDC connector works by using pressure contacts to establish a connection with the wires. The connector has a series of sharp contacts that are aligned with the conductive core of the wire. When the wire is inserted into the connector, the contacts pierce through the insulation and make direct contact with the conductive core. The connector is then typically crimped or compressed to ensure a secure and reliable connection. This displacement of insulation allows for a simple and efficient termination process without the need for stripping individual wires or using additional tools.

3. What are the advantages of using an IDC connector?

There are several advantages to using IDC connectors:

- Easy installation: IDC connectors allow for quick and easy termination of wires, saving time and effort in the installation process.

- Reliable connection: The sharp contacts of the IDC connector ensure a secure and reliable connection, minimizing the risk of signal loss or interruption.

- No need for soldering or crimping: Unlike other types of connectors, IDC connectors do not require soldering or crimping, reducing the complexity and cost of installation.

- Space-saving design: IDC connectors are compact and often feature a low-profile design, making them ideal for applications where space is limited.

- Versatility: IDC connectors are available in various sizes and configurations, allowing for compatibility with different wire gauges and applications.

4. What are some common applications of IDC connectors?

IDC connectors are widely used in various industries and applications, including:

- Computer equipment: IDC connectors are commonly used in computer motherboards, hard drives, and other peripherals to establish connections with cables.

- Telecommunications: They are used in telecommunications equipment, such as modems, routers, and telecommunication panels.

- Consumer electronics: IDC connectors can be found in devices like televisions, game consoles, and audio systems.

- Automotive industry: IDC connectors are used in automotive electronics, such as in-car entertainment systems and dashboard displays.

- Industrial applications: They are utilized in control panels, automation systems, and other industrial equipment.

5. Are IDC connectors suitable for all wire types?

IDC connectors are generally suitable for solid and stranded wires. However, it is essential to ensure that the connector is compatible with the specific wire gauge and insulation material being used. Some IDC connectors may have specific requirements or limitations, so it is important to consult the manufacturer’s specifications or guidelines to ensure proper compatibility and performance.