A resistive touchscreen is a common type of touch-sensitive display used in various devices, including smartphones, tablets, and GPS systems. Unlike capacitive touchscreens that use the electrical properties of our fingertips to detect touch, resistive touchscreens rely on physical pressure to register input.

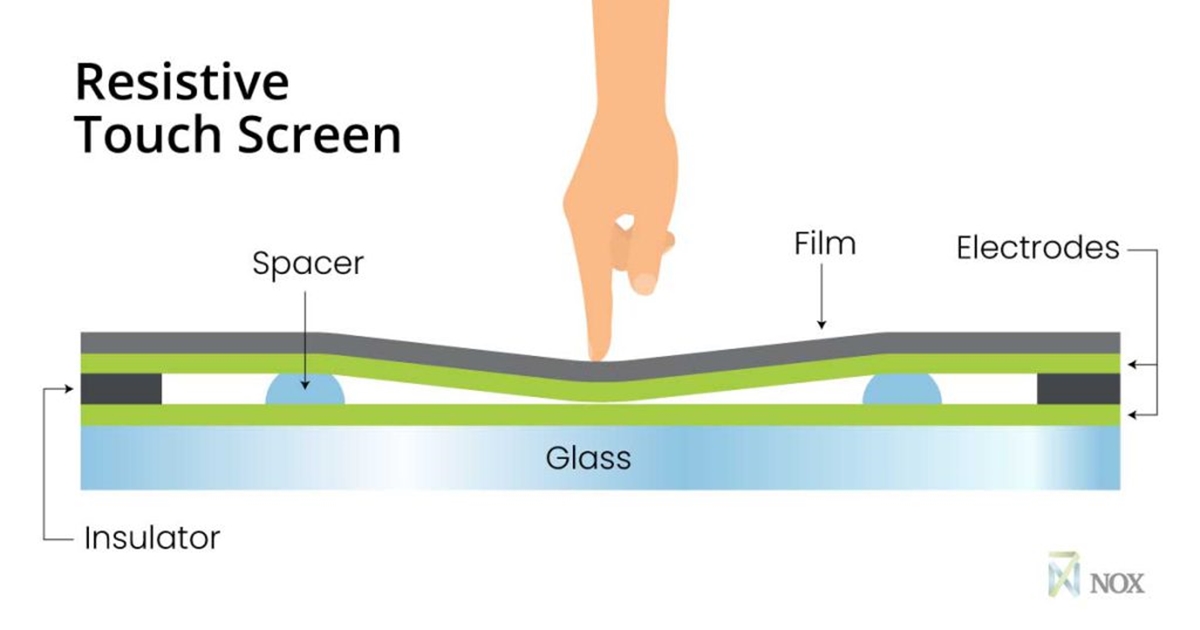

Resistive touchscreens generally consist of multiple layers, including two transparent conductive layers separated by a thin spacer. The outer layer is made of flexible material, while the inner layer is rigid. When pressure is applied to the screen, the two layers make contact, creating an electrical connection at the precise point of touch.

Understanding how a resistive touchscreen works can help users appreciate the technology behind their devices and provide insights into its limitations and advantages. In this article, we will explore the inner workings of a resistive touchscreen, its components, and the benefits it offers in the world of mobile devices and beyond.

Inside This Article

- Basics of Resistive Touchscreens

- Construction and Working Principle

- Indium Tin Oxide (ITO) Layers

- Pressure and Electrical Conductivity

- Touch Sensing

- Interpretation of Touch Inputs

- Advantages and Disadvantages of Resistive Touchscreens

- Conclusion

- FAQs

Basics of Resistive Touchscreens

Resistive touchscreens are one of the most common types of touch-sensitive displays found in mobile devices and other electronic devices. They offer a simple yet effective way to interact with devices by allowing users to input commands and navigate through menus with just the touch of a finger or stylus.

At their core, resistive touchscreens are made up of multiple layers that work together to detect and interpret touch inputs. These layers include a flexible top layer, a spacer layer, and a bottom layer, with each layer playing a crucial role in the functioning of the touchscreen.

The flexible top layer of a resistive touchscreen is typically made of a transparent and flexible material, such as polyester. This layer is coated with a conductive material like indium tin oxide (ITO), which allows for the flow of electrical current.

The spacer layer, as the name suggests, provides a gap or distance between the top and bottom layers of the touchscreen. This gap is necessary to prevent the top and bottom layers from making contact with each other when no touch input is detected.

The bottom layer of the resistive touchscreen is also made of a flexible material and is coated with a conductive material. However, unlike the top layer, the conductive material on the bottom layer is divided into strips or rows, which promotes the flow of electrical current in a specific pattern.

When a user applies pressure on the top layer of a resistive touchscreen, the flexible material makes contact with the conductive material on the bottom layer. This contact creates an electrical circuit between the two layers, allowing for the flow of current.

The touchscreen controller, a crucial component of the resistive touchscreen system, detects the changes in electrical current caused by the touch input. It then translates these changes into precise coordinates on the screen, determining the exact location of the touch.

One key aspect of resistive touchscreens is their ability to detect touch inputs using any object, be it a finger, stylus, or even gloves. This flexibility makes resistive touchscreens highly versatile and user-friendly.

While resistive touchscreens have several advantages such as durability, affordability, and compatibility with various input methods, they also come with a few drawbacks. The layers in resistive touchscreens can cause a loss of image quality, and they may not be as responsive as other touchscreen technologies like capacitive touchscreens.

Despite these limitations, resistive touchscreens continue to be widely used in various applications due to their reliability and compatibility. Understanding the basics of resistive touchscreens can help users make informed decisions when choosing devices that feature this technology.

Construction and Working Principle

Resistive touchscreens are constructed using multiple layers of materials that work together to detect and interpret touch inputs. The two main layers include the top flexible layer, known as the upper substrate, and the bottom layer, called the lower substrate. These layers are typically made of transparent materials such as polyester or glass.

Between the upper and lower substrates, there are additional layers that enable the touch sensing. These layers consist of transparent conductive materials, commonly made from Indium Tin Oxide (ITO). This thin layer of conductive material allows for the flow of electrical current when pressure is applied to the surface of the touchscreen.

The ITO layers are separated by tiny spacers, which maintain a small distance between them when the touchscreen is not being pressed. This air gap prevents the layers from making contact and ensures that the touchscreen remains in a non-activated state until pressure is applied.

When a user touches the surface of a resistive touchscreen, the applied pressure causes the top layer to make contact with the bottom layer. This contact creates a closed electrical circuit between the ITO layers, allowing the flow of current.

The amount of pressure exerted by the user’s touch determines the amount of current that can pass through the layers. The touchscreen controller then measures this change in current to determine the precise location of the touch input.

To accurately sense touch inputs, resistive touchscreens are divided into an X-axis and a Y-axis. The X-axis consists of a series of electrodes on the bottom layer, while the Y-axis consists of corresponding electrodes on the top layer. When a touch is registered, the electrodes in both layers intersect, providing a specific coordinate for the touch location.

The touchscreen controller receives the information from the X and Y axes, interprets the touch coordinates, and relays this data to the device’s operating system. The operating system processes the touch input and performs the appropriate action, such as opening an application, scrolling, or zooming.

Overall, the construction of a resistive touchscreen and its working principle rely on the application of pressure to enable the flow of current and the interpretation of touch coordinates. This technology allows for precise touch inputs and facilitates smooth interaction with mobile devices and other touchscreen-enabled devices.

Indium Tin Oxide (ITO) Layers

Indium Tin Oxide (ITO) is a key element in resistive touchscreens, as it forms the conductive layers necessary for touch sensing. These layers are made up of a transparent film composed of Indium Oxide (In2O3) and Tin Oxide (SnO2) that is deposited onto a glass or plastic substrate. The ITO layer is extremely thin, typically less than a micrometer thick, to maintain the transparency of the screen.

By applying a voltage to these ITO layers, they become conductive, allowing electrical current to flow through them. However, in the absence of pressure or touch, the ITO layers are separated by insulating material, preventing the flow of current between them.

When pressure is applied to the surface of the touchscreen, the top layer of ITO comes into contact with the bottom layer. This creates a conductive path between the layers, allowing the electrical current to flow.

The ITO layers are divided into a grid of rows and columns, with the intersection points serving as touch sensing points. When the layers are connected through touch, the change in current at these intersection points is detected and recognized as a touch input.

It is important to note that the ITO layers in resistive touchscreens are highly sensitive and responsive, capable of accurately detecting even the slightest touch or pressure. This sensitivity allows for precise touch input recognition, making resistive touchscreens suitable for a wide range of applications.

Furthermore, the ITO layers are designed to withstand millions of touches without degradation, ensuring long-lasting durability of the touchscreen. This is essential for devices that require frequent and prolonged use, such as smartphones, tablets, and automotive display systems.

In summary, the Indium Tin Oxide (ITO) layers in resistive touchscreens play a crucial role in touch sensing and input recognition. Their properties of conductivity and transparency enable accurate and responsive touch functionality, making resistive touchscreens a versatile and reliable option for a variety of devices.

Pressure and Electrical Conductivity

When it comes to resistive touchscreens, pressure plays a crucial role in their functionality. The screen surface is made up of multiple layers, and when pressure is applied, these layers come into contact with each other. These layers are typically composed of conductive materials, such as indium tin oxide (ITO).

Pressure applied by a finger or stylus causes the top layer, known as the conductive layer, to come into contact with the bottom layer, called the resistive layer. This creates an electrical connection between the two layers and allows the touchscreen to detect the point of contact.

As the layers make contact, the electrical conductivity of the system changes. The resistive layer, which is made of a material with high resistance, typically exhibits a decrease in resistance at the touchpoint. This change in conductivity is what enables the touchscreen to register the touch and determine its precise location.

By measuring the change in electrical conductivity, the touchscreen controller can calculate the X and Y coordinates of the touch. This data is then passed on to the device’s operating system, which translates it into the appropriate actions on the screen.

It’s important to note that resistive touchscreens require direct physical contact and pressure to register a touch. This is in contrast to capacitive touchscreens, which can detect the touch without any pressure applied.

In summary, the pressure applied to a resistive touchscreen causes the conductive and resistive layers within the panel to come into contact, leading to a change in electrical conductivity. This change is detected by the touchscreen controller, allowing for the accurate interpretation of touch inputs.

Touch Sensing

Once the resistive touchscreen is touched by a user, the layers come into contact at that particular point. The pressure exerted by the touch causes the top layer, typically made of a flexible, conductive material like indium tin oxide (ITO), to deform slightly. This deformation allows the conductive coating to come in direct contact with the lower layer, which also contains a conductive coating.

When the two layers make contact, a closed circuit is created at the touch point. This circuit allows an electrical current to pass through, resulting in a change in the electrical resistance or capacitance of the specific X and Y coordinates where the touch occurred. By measuring the resistance or capacitance values at these coordinates, the touchscreen controller can precisely determine the exact location of the touch.

Touchscreens employ various sensing mechanisms to accurately detect and interpret touch inputs. One common method is called “analog resistive.” In this approach, a voltage is applied to both the X and Y axis of the touchscreen, and the controller measures the change in resistance at the touch point to determine its coordinates.

Another method is called “matrix resistive.” Here, the touch controller scans the X and Y axes sequentially, measuring the resistance at each intersection point. By analyzing the resistance values across the X and Y axes, the controller can identify the precise touch location.

In more advanced resistive touchscreens, the sensing mechanism can be combined with other technologies like capacitive touch or pressure sensors to enhance accuracy, sensitivity, and multi-touch capabilities.

Overall, the touch sensing mechanism in a resistive touchscreen relies on the change in electrical resistance or capacitance when the top and bottom layers make contact. By accurately measuring these changes, the touchscreen controller can translate touch inputs into visual responses on the screen, making it possible for users to interact with their devices seamlessly.

Interpretation of Touch Inputs

Once a resistive touchscreen detects a touch event, the next step is to interpret the touch inputs accurately. This process involves converting the physical interaction into specific commands or actions that the device can understand and respond to. Let’s explore how this interpretation takes place:

1. Coordinate Calculation: The resistive touchscreen measures the X and Y coordinates of the touch location. This information is typically obtained by measuring the amount of electrical current passing through the layers at the point of contact. By analyzing the changes in resistance, the controller can determine the exact position of the touch.

2. Touch Pressure Detection: Resistive touchscreens are capable of detecting the amount of pressure applied by the user. This feature enables devices to differentiate between a light tap and a firmer press. By factoring in the pressure data, applications can implement various functions based on the level of force applied.

3. Multi-Touch Capabilities: Some resistive touchscreens support multi-touch functionality, which allows for multiple touch inputs simultaneously. This advancement enhances user interaction and enables gestures like pinch-to-zoom or two-finger scrolling. The controller needs to interpret the different touch points accurately to recognize and respond to these gestures.

4. Gestures and Gesture Recognition: Resistive touchscreens can interpret specific gestures made by the user. Gestures such as swiping, dragging, or rotating can be interpreted by the software to trigger various actions. Advanced gesture recognition algorithms help ensure accurate interpretation and minimize false positive or false negative responses.

5. Calibration and Calibration Error Correction: Resistive touchscreens often undergo a calibration process to ensure accurate touch input interpretation. Calibration involves mapping the touch coordinates to the display pixels. Inaccurate calibration can lead to misinterpretation of touch inputs. Some touchscreens also implement error correction algorithms to compensate for any drift or calibration inaccuracies that may occur over time.

Overall, the interpretation of touch inputs on a resistive touchscreen involves a combination of hardware and software algorithms. By analyzing the electrical signals and applying sophisticated algorithms, the controller deciphers the user’s intentions accurately, providing a seamless touchscreen experience.

Advantages and Disadvantages of Resistive Touchscreens

Resistive touchscreens have been widely used in various electronic devices for many years. While they offer certain benefits, they also come with their own set of drawbacks. Let’s take a closer look at the advantages and disadvantages of resistive touchscreens.

Advantages:

- Cost-Effective: One of the major advantages of resistive touchscreens is their affordability. They are relatively cheaper to produce compared to other touchscreen technologies, making them a popular choice for budget-friendly devices.

- Compatibility with Gloves and Styluses: Resistive touchscreens can detect input from any object that applies pressure, including gloves and styluses. This makes them suitable for applications where precise input is required, such as digital drawing or signature capture.

- High Accuracy and Precision: Due to their pressure-sensitive nature, resistive touchscreens offer high accuracy and precision for touch inputs. They can accurately detect the location of touch points, making them ideal for applications that require precise control.

- Wide Viewing Angle: Resistive touchscreens provide a wide viewing angle, ensuring that the display remains visible even when viewed from different angles. This makes them suitable for devices with multiple users or situations where the screen needs to be viewed from various positions.

- Durable and Robust: Resistive touchscreens are known for their durability and robustness. They can withstand harsh environments, such as exposure to dust, moisture, and heavy use, without compromising their performance.

Disadvantages:

- Lower Display Quality: One of the main drawbacks of resistive touchscreens is the impact they have on display quality. The additional layers used in the construction of resistive touchscreens can reduce the clarity and brightness of the display, resulting in a slightly lower visual experience compared to other touchscreen technologies.

- Less Responsive: Resistive touchscreens require the application of pressure to register a touch input. This makes them less responsive compared to other touchscreen technologies that operate on capacitive or optical principles. Users may need to exert more force to achieve a desired response.

- Reduced Multi-Touch Capability: Resistive touchscreens generally have limited or no support for multi-touch gestures. They can only detect a single touch point at a time, making them less suitable for applications that heavily rely on multi-touch functionality, such as pinch-to-zoom or rotating objects with two fingers.

- Prone to Wear and Tear: Constantly applying pressure to resistive touchscreens can cause them to wear out over time. The top layer, usually made of soft plastic, is susceptible to scratches and may eventually develop wear patterns. This can impact the accuracy and responsiveness of the touchscreen.

Although resistive touchscreens have their limitations, they continue to be used in various applications where cost-effectiveness, compatibility with different input objects, and durability are important factors to consider. As technology advances, other touchscreen technologies like capacitive and optical touchscreens are gaining popularity, offering improved performance and enhanced user experiences.

Conclusion

In conclusion, resistive touchscreens are an innovative technology that have revolutionized the way we interact with our devices. The functionality and versatility of resistive touchscreens make them an indispensable component in many mobile accessories, such as smartphones and tablets. With their precise touch detection and ease of use, resistive touchscreens provide a seamless and intuitive user experience.

While other touchscreen technologies have emerged in recent years, resistive touchscreens continue to be widely used, thanks to their affordability and durability. Their ability to detect touch through pressure, as well as with a stylus or gloved hand, make them ideal for a variety of applications.

Whether it’s navigating through menus, scrolling through websites, or playing games, resistive touchscreens have become an integral part of our daily lives. As technology continues to advance, we can expect to see even more innovations in the realm of touchscreens, but for now, resistive touchscreens remain a fundamental and reliable choice for mobile accessories.

FAQs

Q: What is a resistive touchscreen?

A: A resistive touchscreen is a type of input device commonly used in smartphones, tablets, and other electronic devices. It consists of two transparent layers with a small gap between them, which, when pressed, allow an electrical current to flow and detect the touch input.

Q: How does a resistive touchscreen work?

A: A resistive touchscreen has two primary layers: the flexible top layer, usually made of polyester, and the rigid bottom layer, typically made of glass or a similar material. Each layer is coated with a resistive material that has conductive properties. When you touch the screen, the layers make contact, creating a circuit and allowing electrical current to flow. The device then calculates the coordinates of the touch based on the location of the electrical signal.

Q: What are the advantages of resistive touchscreens?

A: Resistive touchscreens offer several advantages, including:

1. Versatility: They can be operated using a stylus, finger, or any object that can apply pressure.

2. Accuracy: Resistive touchscreens are highly accurate, enabling precise input and control.

3. Durability: They are resistant to damage from scratches, dust, and liquids, making them suitable for various environments.

4. Cost-effectiveness: Resistive touchscreens are generally more affordable than other types of touchscreens, making them a popular choice for budget devices.

Q: Are there any drawbacks to resistive touchscreens?

A: While resistive touchscreens have their advantages, they also have a few drawbacks:

1. Lower visibility: The presence of multiple layers in resistive touchscreens can reduce display clarity and visibility, compared to other touchscreen technologies like capacitive.

2. Less responsive: Resistive touchscreens require more pressure to register a touch compared to capacitive touchscreens, which can affect the user experience.

3. Limited multitouch support: Resistive touchscreens are typically limited to single-touch input and may not support complex multitouch gestures.

Q: Are resistive touchscreens still used in current smartphones?

A: While resistive touchscreens were more prevalent in the past, they have become less common in modern smartphones. Capacitive touchscreens, which offer better sensitivity and responsiveness, have become the standard for most high-end smartphones. However, resistive touchscreens are still used in certain applications where cost-effectiveness and stylus input are essential, such as some industrial and rugged devices.