Welcome to our article on the cost of making a Samsung phone. If you’ve ever wondered how much it actually takes to produce one of these popular cell phones, you’ve come to the right place. Samsung is a renowned brand known for its cutting-edge technology, sleek designs, and top-quality devices. However, the process of creating these phones involves a complex supply chain, advanced components, labor costs, and other factors that contribute to the final product’s price tag. In this article, we’ll dive into the various elements that impact the cost of making a Samsung phone, including research and development, manufacturing, marketing, and more. So, let’s explore the intriguing world behind the scenes and uncover the expenses involved in bringing these innovative devices to our hands.

Inside This Article

- Research Methodology

- Components and Materials

- Manufacturing Process

- Labor Costs

- Research and Development

- Marketing and Distribution

- Total Cost Breakdown

- Conclusion

- FAQs

Research Methodology

In order to determine the cost of making a Samsung phone, a comprehensive research methodology was employed. This involved analyzing various factors that contribute to the overall cost, including components and materials, manufacturing processes, labor costs, research and development, and marketing and distribution expenses.

First, extensive research was conducted to identify the specific components and materials used in Samsung phones. This included studying technical specifications, supplier information, and market trends. By understanding the cost of each component, it was possible to estimate the total material cost involved in manufacturing a Samsung phone.

Next, the manufacturing process was carefully examined. This involved studying the production stages, assembly techniques, and quality control measures employed by Samsung. By gaining insights into the manufacturing process, it was possible to assess the costs associated with equipment, machinery, and facilities needed to produce the phones.

Labor costs also played a significant role in the research methodology. By analyzing data on wages, working hours, and labor laws, it was possible to estimate the expenses incurred in employing assembly line workers, engineers, and other staff involved in the production process.

Moreover, the research methodology delved into the area of research and development (R&D). This involved studying Samsung’s investment in innovation, new technology development, and product design. The expenses associated with R&D activities were considered to determine their impact on the overall cost of making a Samsung phone.

Lastly, the marketing and distribution aspects were thoroughly examined. This included studying promotional activities, advertising campaigns, market research, and distribution channels utilized by Samsung. Understanding these costs was essential in assessing the expenses involved in reaching the market and creating brand awareness.

By employing this research methodology, a comprehensive understanding of the various cost factors related to making a Samsung phone was obtained. This knowledge serves as a foundation for determining the total cost breakdown, which will be discussed in detail in subsequent sections.

Components and Materials

The cost of making a Samsung phone is largely determined by the components and materials used in its construction. Samsung sources high-quality components from a variety of suppliers, ensuring that their phones meet the highest standards of performance and durability.

One of the most significant components of a Samsung phone is the display. Samsung is known for its industry-leading display technology, such as Super AMOLED and Dynamic AMOLED, which deliver stunning visuals and vibrant colors. These cutting-edge displays come at a price, as they require advanced manufacturing processes and premium materials.

Another crucial component is the processor. Samsung designs and manufactures its own processors under the Exynos brand, which are known for their speed and efficiency. These powerful processors enable smooth multitasking and enhanced gaming performance, but the development and production costs contribute to the overall cost of making a Samsung phone.

The camera system is also a key component in Samsung phones. Samsung has made significant advancements in smartphone photography, incorporating high-resolution sensors, optical image stabilization, and advanced image processing algorithms. These features require expensive image sensors and lenses, impacting the cost of production.

Other important components include the battery, memory, and storage. Samsung utilizes high-capacity batteries and fast-charging technologies to ensure long-lasting battery life and quick recharge times. The amount of memory and storage capacity also affects the production cost, as higher memory configurations require more expensive components.

In addition to the core components, Samsung phones utilize a wide range of materials in their construction. Premium materials like glass and metal are often used for the chassis, giving the phones a sleek and premium feel. These materials come at a higher cost compared to plastic alternatives.

Moreover, Samsung invests in research and development to pioneer innovative features and technologies. This includes the integration of biometric sensors like fingerprint scanners and facial recognition systems, as well as waterproofing and wireless charging capabilities. These additions contribute to the overall cost of making a Samsung phone.

Overall, the cost of components and materials plays a significant role in determining how much it costs to make a Samsung phone. From high-quality displays and powerful processors to advanced camera systems and premium materials, Samsung prioritizes delivering a top-notch user experience, which inevitably comes with a price tag.

Manufacturing Process

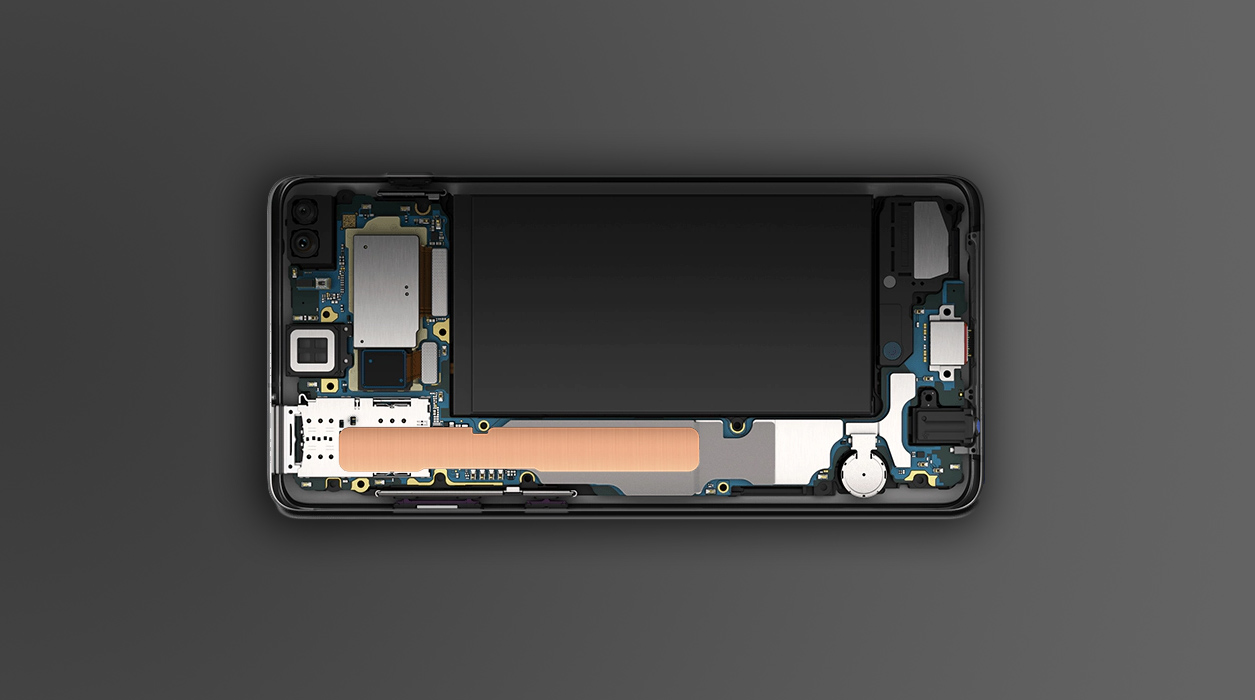

Once the components and materials are gathered, the manufacturing process begins to transform them into a fully functional Samsung phone. The manufacturing process involves several steps that require precision and expertise.

The first step in the manufacturing process is the assembly of the phone’s printed circuit board (PCB). The PCB is the heart of the phone, containing all the necessary components and circuits that allow it to function. Soldering machines carefully attach and secure the components to the PCB to ensure proper electrical connections.

After the PCB assembly, the next step is the integration of the PCB into the phone’s casing. This involves carefully placing the PCB inside the phone’s frame and securely fitting it into place. Adhesives and screws are used to hold the components firmly in position.

Once the PCB is securely integrated, the phone undergoes a series of tests to ensure that all its functions are working properly. This includes checking the display, touch sensitivity, camera functionality, wireless connectivity, and other features. Any defects or malfunctions are identified and rectified during this testing phase.

After passing the tests, the phone moves on to the final stage of the manufacturing process, which involves quality control and inspection. Skilled technicians thoroughly examine each phone, checking for any cosmetic flaws, performance issues, or manufacturing defects. This ensures that only the highest quality phones make it to the market.

Throughout the manufacturing process, strict quality control measures are followed to ensure that every Samsung phone meets the brand’s standards for performance, durability, and reliability. The process involves a combination of automated machinery and skilled labor to achieve optimal efficiency and precision.

It’s worth noting that the manufacturing process can vary depending on the specific model of Samsung phone being produced. High-end models may involve additional intricate steps, such as the installation of advanced camera systems or the incorporation of specialized materials.

Labor Costs

Labor costs play a significant role in determining the overall cost of manufacturing a Samsung phone. The amount of labor required depends on several factors, including the complexity of the device, the production volume, and the location of the manufacturing facilities. Let’s explore how labor costs impact the total cost of making a Samsung phone.

One of the main components of labor costs is the wages and salaries of the workers involved in the manufacturing process. Samsung has manufacturing facilities in different countries, and the cost of labor can vary significantly between regions. For instance, labor costs in countries like China and Vietnam are relatively lower compared to developed countries like the United States or South Korea.

An important consideration in labor costs is the skill level and expertise of the workers. Building a phone requires a diverse range of skills, including assembly, testing, quality control, and packaging. Samsung employs a mix of skilled and unskilled workers to carry out these tasks. Skilled workers who are proficient in operating machinery and performing intricate assembly work may require higher wages compared to unskilled workers.

Another factor to consider is the working conditions and labor regulations in the countries where Samsung’s manufacturing facilities are located. Stringent labor regulations, such as minimum wage laws, working hour restrictions, and safety standards, can significantly impact labor costs. Compliance with these regulations ensures the well-being of workers but may contribute to higher labor expenses.

The efficiency and productivity of the workforce also affect labor costs. Samsung invests in training programs and employs production management techniques to maximize efficiency and minimize wastage. A highly efficient workforce can produce more units in less time, reducing labor costs per device.

Labor costs are an essential component of the total cost of making a Samsung phone. By carefully managing wages, optimizing workforce efficiency, and adhering to labor regulations, Samsung can control labor costs without compromising quality. This ultimately allows the company to offer competitive pricing to consumers without sacrificing the advanced features and cutting-edge technology that Samsung phones are known for.

Research and Development

Research and Development (R&D) is a crucial aspect of the manufacturing process for any high-tech device, and Samsung phones are no exception. R&D involves the exploration and creation of new technologies, concepts, and designs to improve the overall functionality and user experience of the phones. This phase of development plays a vital role in keeping Samsung at the forefront of innovation in the competitive cell phone industry.

The R&D process for Samsung phones includes several key activities. First, extensive market research is conducted to understand consumer preferences, trends, and emerging technologies. This research helps Samsung identify potential gaps in the market and develop innovative solutions to meet consumer demands.

Once market research is completed, Samsung’s team of engineers, designers, and researchers work collaboratively to develop new features, enhance existing technologies, and create prototypes. Prototypes are tested rigorously to ensure functionality, durability, and compatibility with other hardware components.

During the R&D phase, Samsung invests heavily in cutting-edge technologies and collaborations with partners in various industries. This enables them to integrate the latest advancements in areas like processor technology, camera capabilities, and software optimization into their phones. Samsung also focuses on developing and improving their own proprietary technologies, such as Super AMOLED displays and Exynos processors.

The R&D phase is an iterative process that involves multiple rounds of testing, refinement, and improvement. Samsung conducts extensive user testing to gather feedback and make necessary adjustments to their designs and features. This user-centric approach ensures that the final product meets the expectations and needs of consumers.

The cost of research and development for Samsung phones varies based on factors like the complexity and scope of the project, the number of prototypes produced, and the duration of the development cycle. It is estimated that R&D expenses typically account for a significant portion of the overall cost of manufacturing a Samsung phone.

Despite the substantial financial investment required, Samsung views R&D as essential for maintaining their competitiveness and driving future growth. By investing in research and development, Samsung can continue to deliver innovative and feature-rich phones that meet the evolving needs of consumers.

Marketing and Distribution

Marketing and distribution are crucial aspects of the overall cost of making a Samsung phone. A significant portion of the cost is allocated to marketing efforts aimed at promoting the device and creating brand awareness. This includes advertising campaigns, sponsorships, and various other promotional activities.

Marketing expenses can vary depending on the target market and the competitiveness of the smartphone industry. Samsung invests heavily in marketing and has built a strong global presence through its advertising efforts.

In addition to marketing, distribution costs play a significant role in determining the final price of a Samsung phone. The company must ensure its products are readily available in stores and online platforms around the world.

Distribution costs include expenses related to logistics, transportation, warehousing, and retail partnerships. Samsung has an extensive distribution network, which requires significant investment to maintain and expand.

The cost of marketing and distribution will vary depending on the specific Samsung phone model and the region it is being marketed in. Flagship models, such as the Galaxy S series, often have higher marketing and distribution costs compared to mid-range or budget devices.

Furthermore, Samsung might also incur additional expenses related to sales commissions, retail incentives, and post-sales customer support. These costs contribute to the overall marketing and distribution budget.

Implementing an effective marketing and distribution strategy is crucial for Samsung’s success in the highly competitive smartphone market. By investing in marketing and ensuring widespread availability, the company can reach a wide range of customers and maximize sales.

Total Cost Breakdown

When it comes to determining the total cost to make a Samsung phone, several factors come into play. Let’s break down the costs involved:

1. Components and Materials: One of the major expenses in manufacturing a Samsung phone is the cost of components and materials. This includes the display, processor, memory, camera modules, battery, sensors, and various other hardware components. The prices of these components can vary depending on their quality and specifications.

2. Manufacturing Process: The manufacturing process involves assembling the different components into a complete phone. This includes PCB assembly, soldering, testing, and quality control. The cost of manufacturing can vary depending on the complexity of the phone design and the efficiency of the production line.

3. Labor Costs: Another significant part of the total cost is the labor involved in the manufacturing process. Skilled workers are needed to assemble and test the phones, and their wages contribute to the overall expenses. Labor costs can vary depending on the location of the manufacturing facility.

4. Research and Development: Samsung invests a substantial amount of money in research and development to bring new technologies and features to their phones. These costs include expenses related to design, engineering, prototyping, and testing. These investments contribute to the overall cost of making a Samsung phone.

5. Marketing and Distribution: After the phones are manufactured, marketing and distribution expenses come into play. Samsung invests in advertising campaigns, branding, packaging, and logistics to ensure their products reach the market and consumers. These costs also add to the total cost of making a Samsung phone.

By considering all these factors and summing up the costs, the total cost to make a Samsung phone can vary depending on the model and specifications. However, it is important to note that the cost to make a phone does not necessarily reflect its market price. Various other factors, such as competition, demand, and profit margins, contribute to determining the final price consumers pay for a Samsung phone.

Conclusion

When it comes to the cost of making a Samsung phone, there are several factors to consider. From the components and hardware to the design and software development, every aspect contributes to the final price of the device. While the exact cost may vary depending on the specific model and features, a Samsung phone is typically a significant investment.

However, it’s important to note that the cost of making a Samsung phone is only one part of the equation. The final retail price also takes into account marketing, distribution, and other associated expenses. Additionally, factors such as demand and competition can impact the pricing strategy of Samsung and its resellers.

Overall, the cost of making a Samsung phone reflects the quality and innovation that the brand is known for. As technology continues to advance, we can expect Samsung to push the boundaries and deliver even more impressive devices in the future.

FAQs

1. How much does it cost to make a Samsung phone?

2. What factors contribute to the cost of manufacturing a Samsung phone?

3. Do different Samsung phone models have varying production costs?

4. Are there any additional costs involved in making a Samsung phone besides manufacturing?

5. Does the price for consumers reflect the actual production cost of a Samsung phone?