In the world of electronics and robotics, having control over motor speed is crucial for various applications. One interesting and versatile method to achieve this control is by using a joystick. A joystick is a popular input device that enables users to manipulate the movement of objects in a smooth and intuitive way. When combined with the power of microcontrollers and motor drivers, it becomes possible to control the speed of motors with precision and ease.

In this article, we will explore how to control motor speed using a joystick. We will discuss the components and equipment needed, as well as the step-by-step process of connecting and programming them. Whether you are a hobbyist, a student, or a professional engineer, understanding how to control motor speed with a joystick opens up a world of possibilities for building interactive projects and designing innovative solutions.

Inside This Article

- Overview of DMotor Speed Control System

- Understanding Joysticks

- Connecting Joystick to DMotor Speed Controller

- Controlling DMotor Speed with Joystick

- Conclusion

- FAQs

Overview of DMotor Speed Control System

The DMotor Speed Control System is a technology that allows users to precisely control the speed of a motor. It is widely used in various industries and applications such as robotics, automation, industrial machinery, and more.

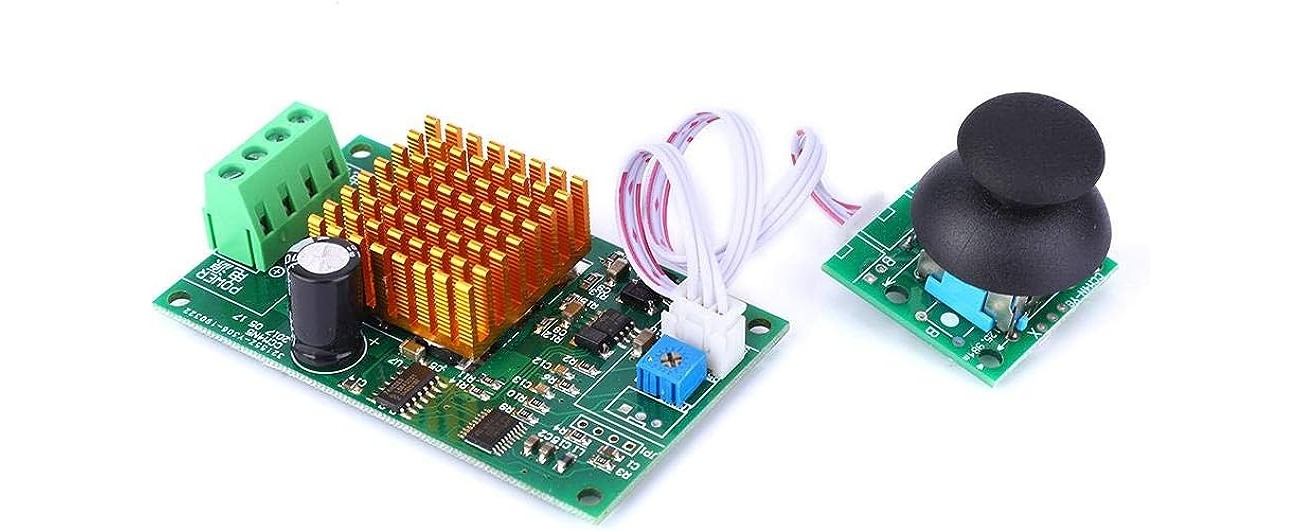

The system consists of two main components: the motor and the speed controller. The motor is responsible for generating the mechanical power, while the speed controller regulates the amount of power supplied to the motor, thereby controlling its speed.

DMotor speed control systems are designed to provide smooth and accurate speed adjustments, allowing for efficient operation and optimal performance of the motor. They can handle a wide range of motor types, including DC motors, AC motors, and stepper motors.

These systems offer several advantages to users. Firstly, they provide precise control over the motor speed, allowing for better coordination and synchronization with other devices or processes. This is crucial in applications where precise speed control is required for accurate positioning or smooth operation.

Additionally, DMotor speed control systems enhance the overall efficiency of motor-driven systems. By regulating the speed of the motor based on the system requirements, unnecessary power consumption can be minimized, resulting in energy savings and cost reductions.

Moreover, these systems also contribute to the longevity and reliability of motors by preventing excessive wear and tear. By maintaining a consistent speed and avoiding abrupt speed changes, the motor’s components experience less stress, leading to enhanced durability and extended lifespan.

Overall, the DMotor Speed Control System offers a range of benefits, including precise speed control, improved efficiency, and increased motor lifespan. It is a critical technology for various industries and applications, providing users with enhanced performance and productivity.

Understanding Joysticks

A joystick is a popular type of input device used to control the movement of objects on a screen, such as in video games or computer simulations. It consists of a handheld lever that can be moved in various directions to provide input signals to the device it is connected to. Joysticks come in different designs and configurations, but they all work on a similar principle.

Most joysticks consist of two main components: the base and the stick. The base is the stationary part of the joystick that houses the electronic circuitry and the connections. It is usually placed on a flat surface, such as a desk or a console. The stick, on the other hand, is the movable part of the joystick that the user holds and manipulates to control the movement.

The stick of a joystick typically has a pivoting mechanism that allows it to move in multiple directions. It can be moved up, down, left, or right, and it often has the ability to be pushed or pulled as well. These movements generate signals that are sent to the connected device, providing input that can be interpreted and acted upon.

Joysticks commonly use analog technology, which means that they can provide a continuous range of input values rather than just on/off signals. This allows for precise control of the movements and actions in the associated software or game. Analog joysticks work by sensing the position of the stick within a defined range and converting it into a corresponding electrical signal.

Some joysticks also incorporate additional features, such as buttons or triggers, that can be used to perform specific actions or commands. These extra input options provide further flexibility and functionality to the user.

In addition to their uses in gaming and simulations, joysticks have found applications in various other fields. They are commonly used in aircraft and spacecraft controls, robotics, virtual reality systems, and even certain medical devices. The versatility and intuitive nature of joysticks make them an essential interface for precise and responsive control.

Overall, understanding how joysticks work and their various components is crucial when it comes to using them for control purposes. With this knowledge, you can effectively connect and utilize a joystick to control the speed and movement of a DMotor or any other compatible device.

Connecting Joystick to DMotor Speed Controller

Connecting a joystick to a DMotor speed controller allows for precise and intuitive control over the motor speed. The process involves a few simple steps, outlined below:

1. Identify the pinouts: Most joysticks come with a connector that has multiple pins. These pins correspond to different control signals such as X-axis, Y-axis, ground, and power. Consult the joystick’s datasheet or manual to determine the pinout configuration.

2. Determine the voltage requirements: Check the voltage specifications of both the joystick and the DMotor speed controller. Ensure they are compatible, as mismatched voltages can damage the components. Most joysticks and speed controllers operate on a 5V or 3.3V power supply.

3. Connect the power supply: Connect the power supply pins of the joystick and speed controller. Ensure that the ground pins are connected correctly to establish a common ground reference for both devices. This is crucial for proper communication and control.

4. Connect the control signals: Locate the X-axis and Y-axis pins on the joystick connector. Connect these pins to the appropriate input pins on the DMotor speed controller. These pins are responsible for relaying the joystick’s position information to the controller.

5. Check for additional pins: Some joysticks may have additional pins for buttons or other auxiliary features. If you want to utilize these additional functions, consult the joystick’s datasheet or manual to understand their purpose and how to connect them to the DMotor speed controller.

6. Test the connection: Once all the connections are made, power on the joystick and DMotor speed controller. Move the joystick in different directions and observe if the motor speed changes accordingly. If the motor speed is not responding as expected, check the wiring and ensure that all connections are secure.

7. Fine-tune the control: Depending on the specific DMotor speed controller, you may have additional options to adjust the motor speed control. This can include setting speed limits, acceleration rates, or sensitivity. Consult the controller’s manual or documentation to understand these options and optimize the motor control to your desired specifications.

By following these steps, you can successfully connect a joystick to a DMotor speed controller and gain precise control over the motor speed. This opens up a world of possibilities for applications that require accurate speed adjustments, such as robotic systems, RC vehicles, or industrial machinery.

Controlling DMotor Speed with Joystick

Now that we have the joystick connected to the DMotor speed controller, let’s explore how to control the speed of the motor using the joystick.

The joystick typically has two axes, the X-axis and the Y-axis, which correspond to the horizontal and vertical movements, respectively. These axes allow us to control the motor speed in a smooth and intuitive manner.

To control the motor speed using the joystick, we need to map the joystick movements to different speed levels. For example, pushing the joystick all the way forward on the Y-axis could correspond to maximum speed, while pulling it all the way back could correspond to minimum speed.

We can use analog-to-digital conversion techniques to convert the continuous joystick movements into discrete speed levels. The joystick position can be read as a voltage value, which can then be mapped to a specific speed level using the DMotor speed controller.

Once we have mapped the joystick movements to speed levels, we can use the DMotor speed controller to set the motor speed accordingly. The controller takes the speed level as input and adjusts the motor’s voltage and current to achieve the desired speed.

Additionally, we can also incorporate other features like acceleration and deceleration control. This allows us to smoothly ramp up or slow down the motor speed based on the joystick position, giving us precise control over the motor’s performance.

It’s worth noting that the specific steps and methods for controlling the DMotor speed with a joystick may vary depending on the controller and joystick model being used. Therefore, it’s essential to refer to the manufacturer’s documentation for detailed instructions on how to set up and program the speed control system.

Controlling DMotor speed with a joystick opens up a wide range of possibilities for various applications. Whether it’s in robotics, gaming, or industrial automation, the joystick provides a convenient and intuitive way to interact with the motor and fine-tune its speed according to specific requirements.

So, go ahead and explore the exciting world of DMotor speed control with a joystick. With practice and experimentation, you’ll be able to achieve precise control and unlock the full potential of your motorized systems.

Overall, controlling a motor speed with a joystick is a fascinating and practical concept. It allows for precision, flexibility, and intuitive control over the motor’s motion. Whether you are building a robotics project or working on industrial automation, the ability to vary the motor speed using a joystick opens up a world of possibilities.

By combining the power of a microcontroller, motor driver, and joystick, you can create complex motion control systems that are easy to operate. The ability to control the motor speed with a joystick gives you the freedom to execute smooth and precise movements, making it a valuable tool for various applications.

Remember to choose the right components, follow the necessary wiring and coding guidelines, and calibrate your system properly to achieve optimal performance. With the information and steps provided in this article, you should now have a good understanding of how to control motor speed with a joystick.

So, go ahead and start exploring the world of joystick-controlled motor systems. Unleash your creativity, build amazing projects, and enjoy the endless possibilities that come with this exciting technology!

FAQs

Q: How can I control the motor speed using a joystick?

A: You can control the motor speed with a joystick by connecting the joystick to a microcontroller or an Arduino board. The joystick’s movements can be mapped to specific motor speed values, which can then be translated into signals that control the motor’s speed and direction using motor driver circuits.

Q: Can I control the speed of any type of motor with a joystick?

A: In most cases, you can control the speed of DC motors and some types of stepper motors using a joystick. However, the ability to control the speed of AC motors usually requires more complex control systems and is not typically achieved directly using a joystick.

Q: What are some applications where motor speed control with a joystick is useful?

A: Motor speed control using a joystick is useful in various applications such as robotics, RC vehicles, automation systems, and even industrial machinery. It provides precise control over the motors’ speed, allowing for smooth and accurate movements in different applications.

Q: Can I control multiple motors simultaneously with a joystick?

A: Yes, you can control multiple motors simultaneously with a joystick by using a microcontroller or an Arduino board with enough digital or analog pins available. Each motor will require a separate motor driver circuit, and the joystick’s movements can be mapped to control the speed and direction of each motor independently.

Q: Are there any specific joystick models or motor driver circuits recommended for motor speed control?

A: There are various joystick models available that can be used for motor speed control, such as analog joysticks or digital joysticks with I2C or SPI communication. As for motor driver circuits, popular choices include H-bridge motor drivers for controlling DC motors and stepper motor driver modules for controlling stepper motors. The specific choice of the joystick and motor driver circuit will depend on your project requirements and the type of motors you are working with.