The OBD connector, also known as the On-Board Diagnostics connector, is an essential component in modern automobiles. It serves as a communication link between the vehicle’s onboard computer system and external diagnostic tools. By connecting to the OBD connector, mechanics, technicians, and even car enthusiasts gain access to valuable information about the vehicle’s performance and diagnostic data.

From monitoring engine parameters to retrieving trouble codes, the OBD connector provides a gateway to access real-time data and perform various diagnostic tasks. Its presence has revolutionized the way vehicles are diagnosed and serviced, enabling faster and more accurate troubleshooting.

In this comprehensive guide, we will delve into the details of the OBD connector, explore its functions, and highlight its importance in modern automotive technology. So, if you’re curious about the OBD connector and all that it entails, read on to expand your knowledge of this vital automotive component.

Inside This Article

- Purpose of an OBD Connector

- Types of OBD Connectors

- Common Communication Protocols Used

- Diagnostic Functions Enabled by OBD Connectors

- Conclusion

- FAQs

Purpose of an OBD Connector

An On-Board Diagnostics (OBD) connector is a vital component of modern vehicles that allows for communication between the vehicle’s electronic control unit (ECU) and external devices. The primary purpose of an OBD connector is to diagnose and monitor the performance of a vehicle, helping to identify and resolve any potential issues or malfunctions.

The OBD connector serves as a gateway, providing access to valuable data from various sensors and systems within the vehicle. This data includes engine performance, emissions levels, and the status of various vehicle systems. By connecting to the OBD port, mechanics, technicians, and even vehicle owners can gain insights into the health and condition of the vehicle.

One of the key functionalities of the OBD connector is to enable the retrieval of diagnostic trouble codes (DTCs). These codes are generated by the vehicle’s ECU when it detects an issue or malfunction in one of the systems. The OBD connector allows these codes to be read using a diagnostic scan tool, helping pinpoint the specific problem area.

Additionally, the OBD connector allows for real-time monitoring of live data. This means that users can access and view important parameters, such as engine RPM, vehicle speed, coolant temperature, and more. This data can be invaluable when assessing the performance of the vehicle or diagnosing complex issues.

Moreover, the OBD connector enables the implementation of emission control systems, ensuring that vehicles adhere to environmental regulations. By monitoring emissions levels and providing feedback to the ECU, the OBD connector helps optimize engine performance and reduce harmful emissions.

Furthermore, the OBD connector plays a crucial role in vehicle maintenance and service. By connecting to the OBD port, technicians can perform tasks such as resetting service intervals, reprogramming the ECU, and conducting software updates. This enhances the overall performance and longevity of the vehicle.

Types of OBD Connectors

When it comes to OBD connectors, there are primarily two types that are commonly used – the OBD-I and OBD-II connectors. Let’s take a closer look at each of these types:

1. OBD-I Connectors: The OBD-I connectors were the first generation of On-Board Diagnostics connectors used in vehicles. These connectors were introduced in the early 1980s and were standardized to allow for diagnostic communication between the vehicle’s computer system and external devices. However, it is important to note that the design and pin configurations of OBD-I connectors vary depending on the vehicle manufacturer, making them less standardized than their OBD-II counterparts.

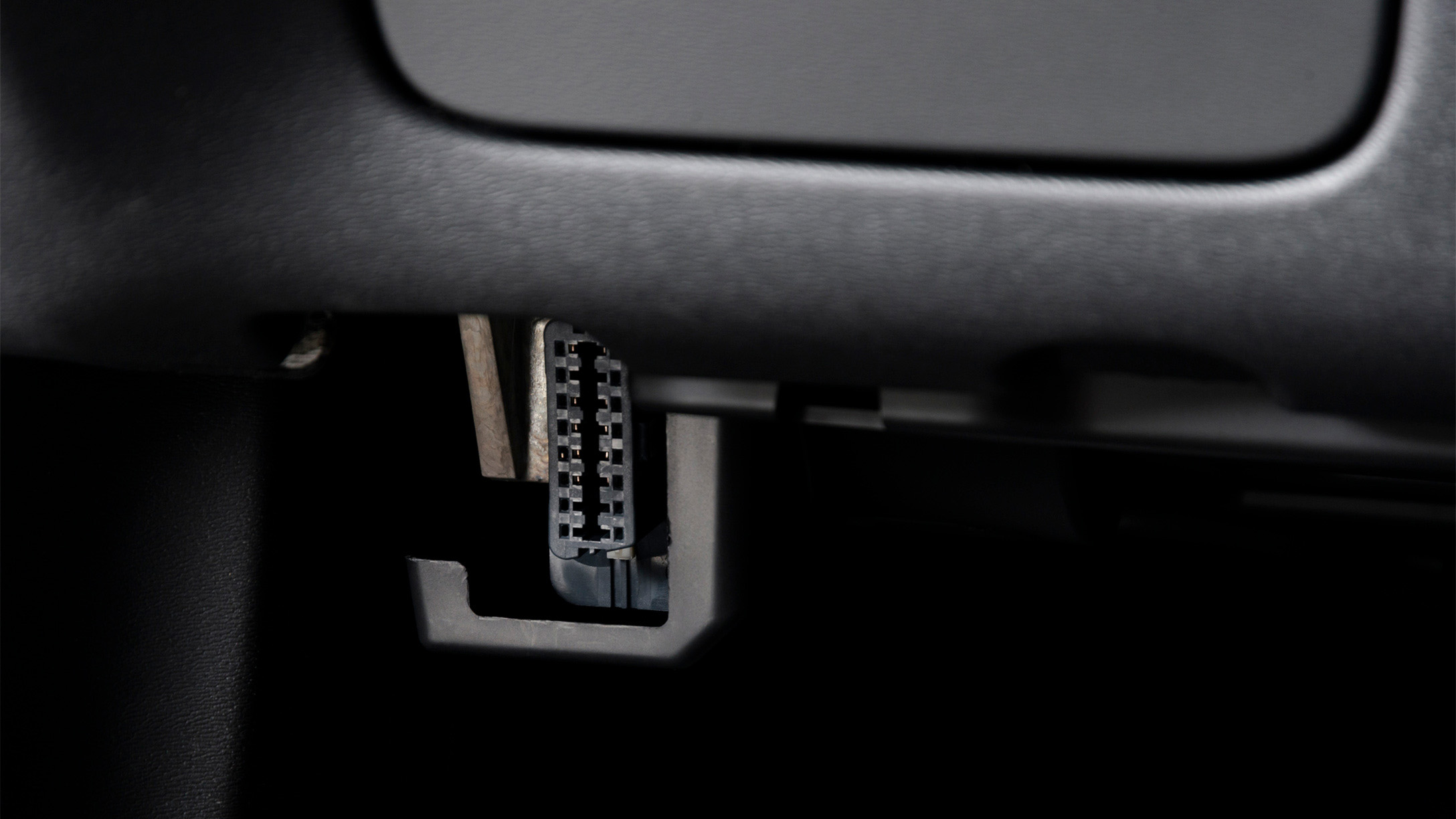

2. OBD-II Connectors: The OBD-II connectors are the current standard for most vehicles on the road today. These connectors were introduced in the mid-1990s and are required to be present in all cars and light trucks sold in the United States since 1996. OBD-II connectors have a standardized pin configuration, making them more versatile and compatible with a wide range of diagnostic tools and devices. They have a 16-pin connector and are typically located near the driver’s side dashboard or under the steering column.

In addition to the two main types mentioned above, it is worth noting that within the OBD-II category, there are different connector types, such as the J1962 connector used in most vehicles, and the J1939 connector used in heavy-duty trucks and diesel-powered vehicles. These variations exist to accommodate different communication protocols and vehicle systems.

Common Communication Protocols Used

When it comes to OBD connectors, there are several common communication protocols used to transmit data between the vehicle’s onboard computer system and the diagnostic tool. These protocols define the rules and specifications for data transfer, allowing the diagnostic tool to communicate effectively with the vehicle.

Let’s take a closer look at some of the widely used communication protocols in OBD connectors:

- SAE J1850 PWM (Pulse Width Modulation): This protocol was introduced by the Society of Automotive Engineers (SAE) and was commonly used in vehicles manufactured by Ford and some Chrysler models. It uses variable pulse width modulation to transmit data.

- SAE J1850 VPW (Variable Pulse Width): Similar to the PWM protocol, the VPW protocol is also developed by the SAE. It was mainly used in General Motors (GM) vehicles. It employs a variable pulse width to transmit information between the vehicle’s onboard computer system and the diagnostic tool.

- ISO 9141-2: This protocol is an international standard and is commonly used in vehicles manufactured in Europe and Asia. It is a slower communication protocol compared to others, but it is still widely supported by many diagnostic tools.

- ISO 14230 KWP2000 (Keyword Protocol 2000): The KWP2000 protocol is another international standard commonly used in vehicles worldwide. It allows for faster communication and more advanced diagnostic functions.

- ISO 15765-4 CAN (Controller Area Network): The CAN protocol is becoming increasingly popular in modern vehicles. It offers faster and more reliable communication, making it ideal for diagnostic purposes. It is used in both passenger cars and commercial vehicles.

- SAE J1939: This protocol is primarily used in heavy-duty vehicles and off-road equipment. It is based on the CAN protocol but incorporates additional specifications to meet the requirements of commercial vehicles.

These are just a few examples of the common communication protocols used in OBD connectors. It’s important to note that different vehicle manufacturers may use different protocols, so it’s crucial to ensure compatibility between the diagnostic tool and the vehicle’s OBD system.

By understanding these protocols, you can select the appropriate diagnostic tool that supports the specific protocol used in your vehicle, enabling you to effectively diagnose and troubleshoot any issues.

Diagnostic Functions Enabled by OBD Connectors

Modern vehicles are equipped with On-Board Diagnostic (OBD) systems, which serve as a vital tool for identifying and troubleshooting issues with engine performance. These systems rely on OBD connectors to establish a link between the vehicle’s onboard computer and diagnostic tools. OBD connectors enable a wide range of diagnostic functions, allowing technicians to quickly and accurately diagnose and address potential problems.

Here are some of the key diagnostic functions enabled by OBD connectors:

- Reading Diagnostic Trouble Codes (DTCs): OBD connectors provide access to the vehicle’s computer, allowing technicians to retrieve DTCs. These codes provide valuable information about specific issues or faults detected by the onboard computer. By reading these codes, technicians can pinpoint the problem area and take appropriate action.

- Live Data Monitoring: OBD connectors enable real-time data monitoring of various engine parameters, such as engine speed, coolant temperature, oxygen sensor readings, fuel trims, and more. This live data allows technicians to analyze the engine’s performance and identify any abnormalities or irregularities that may be affecting its operation.

- Vehicle Sensor Calibration: OBD connectors provide the ability to calibrate and reset various sensors in the vehicle. This calibration ensures that the sensors are accurately reporting data to the onboard computer, improving the overall performance and efficiency of the vehicle.

- Clearing DTCs: Once a problem has been diagnosed and resolved, OBD connectors enable technicians to clear the DTCs from the vehicle’s computer. Clearing the codes resets the system and allows the technician to verify if the issue has been successfully resolved.

- Performance Testing: OBD connectors can facilitate performance tests, such as acceleration tests, brake tests, and emissions tests. These tests help assess the overall performance and compliance of the vehicle with environmental regulations.

- Software Updates and Programming: OBD connectors allow for the installation of software updates and reprogramming of the vehicle’s computer. This ensures that the vehicle’s software is up to date, optimizing performance, and addressing any known software-related issues.

By utilizing these diagnostic functions enabled by OBD connectors, technicians can efficiently diagnose and resolve issues with vehicle performance, leading to improved reliability, efficiency, and customer satisfaction.

After exploring the world of OBD connectors, it is clear that these small devices play a crucial role in vehicle diagnostics and monitoring. They provide a gateway for accessing valuable information about the performance and health of our cars, enabling us to troubleshoot issues and make informed maintenance decisions.

Whether you are a DIY enthusiast or a professional mechanic, having an OBD connector is essential for staying on top of your vehicle’s condition. From checking engine codes to tracking fuel efficiency, these connectors offer a wide range of functionalities that can save time, money, and frustration.

With the ever-advancing technology in the automotive industry, it is exciting to see what the future holds for OBD connectors. As cars become more connected and autonomous, we can expect even more advanced diagnostics and real-time data analysis through these connectors.

So, whether you are looking to diagnose a problem, monitor your vehicle’s health, or simply stay ahead of maintenance, investing in an OBD connector is a wise decision. It will empower you with the knowledge and insights required to keep your car running smoothly and efficiently, bringing you peace of mind on every journey.

FAQs

1. What is an OBD connector?

The OBD connector, also known as the On-Board Diagnostic connector, is a standardized port found in most vehicles manufactured since the mid-1990s. It provides access to the vehicle’s onboard computer system, allowing for diagnostic and troubleshooting procedures.

2. What does an OBD connector do?

The OBD connector serves as a link between the vehicle and various diagnostic tools, such as code readers and scanners. It enables users to retrieve important information about the vehicle’s performance, check for diagnostic trouble codes (DTCs), and monitor real-time data.

3. Where is the OBD connector located?

The exact location of the OBD connector can vary depending on the vehicle make and model. However, it is commonly found under the dashboard on the driver’s side, near the steering column. Some vehicles may have it positioned in the center console or inside the glove compartment.

4. Do all vehicles have an OBD connector?

Not all vehicles have an OBD connector, especially older models that predate the OBD system. The OBD system became mandatory in the United States for gasoline-powered vehicles starting in 1996. However, it is always best to check your vehicle’s owner’s manual or consult with a professional to verify if your vehicle has an OBD connector.

5. Can I use any OBD scanner with my vehicle?

Most OBD scanners are designed to be universal and compatible with all vehicles with an OBD connector. However, it is important to ensure that the scanner you choose supports the specific OBD protocol used by your vehicle. There are five different OBD protocols, including OBD-I, OBD-II, and the newer CAN protocol.