In the world of automotive repairs, certain issues can crop up unexpectedly, causing frustration for vehicle owners. One such issue is a wire harness failure in the 2009 Chrysler Town & Country (T&C). The wire harness serves as a vital component in the vehicle’s electrical system, and when it fails, it can lead to numerous complications.

In this article, we will delve into the problematic area surrounding a wire harness failure in the 2009 Chrysler T&C and explore what options vehicle owners have for repairing or replacing a CAN bus connector. Whether you find yourself facing a malfunctioning wire harness or simply want to be prepared for any future issues, read on to learn more about this common problem and how to address it effectively.

Inside This Article

- Understanding the Can Bus Connector

- Signs of Wire Harness Failure: List of Symptoms Indicating a Potential Wire Harness Failure and How to Identify if the CAN Bus Connector is the Source of the Issue

- Repairing the Wire Harness- Step-by-step guide on repairing the wire harness- Tools and materials required for the repair process- Troubleshooting tips for resolving any connectivity issues

- Replacing the Can Bus Connector

- Conclusion

- FAQs

Understanding the Can Bus Connector

The CAN bus system, or Controller Area Network, is a vital component in modern vehicles. It is responsible for facilitating communication between different electronic control units (ECUs) within the car. The system allows these ECUs to share data, such as engine parameters, sensor readings, and control signals.

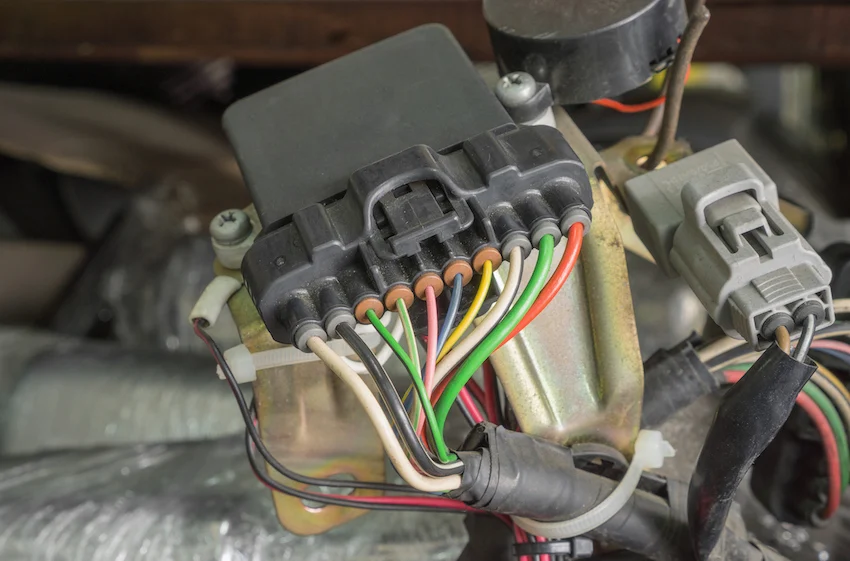

The can bus connector plays a crucial role in the CAN bus system by acting as a gateway for transmitting data signals between various ECUs. It serves as a centralized hub that connects different components of the vehicle’s electrical system, enabling seamless communication and coordination between them.

However, like any other electrical component, the can bus connector is susceptible to wear and tear, which can lead to several issues, including wire harness failure. This failure can disrupt the smooth transmission of data signals, resulting in malfunctioning systems and potential safety hazards.

There are several common issues that can contribute to wire harness failure in the can bus connector. One such issue is corrosion due to exposure to moisture or contaminants. Corrosion can cause a poor connection between the wires and the connector terminals, leading to signal losses or intermittent communication problems.

Another issue is physical damage to the wire harness, such as cuts, frays, or breaks. These damages can occur due to accidents, improper installation, or constant vibration and movement of the vehicle. When the wires are damaged, they can cause disruptions in the signal transmission, affecting the performance of connected systems.

Additionally, improper handling or repair attempts can also contribute to wire harness failure. Mishandling the connector or using incorrect tools and techniques during repairs can cause further damage to the wiring or connector pins, exacerbating the connectivity issues.

It’s important to understand the potential issues that can lead to wire harness failure in the can bus connector. By recognizing these problems, vehicle owners and technicians can take appropriate measures to prevent or address them, ensuring the smooth functioning of the CAN bus system and maintaining the overall health of the vehicle.

Signs of Wire Harness Failure: List of Symptoms Indicating a Potential Wire Harness Failure and How to Identify if the CAN Bus Connector is the Source of the Issue

A wire harness failure in a vehicle can cause various issues, including electrical malfunctions and communication errors. Recognizing the signs of wire harness failure, particularly related to the CAN bus connector, is crucial in identifying and addressing the problem promptly. Here are some common symptoms that indicate a potential wire harness failure:

- Intermittent electrical problems: If you experience sporadic issues with your electronics, such as power windows not functioning properly, radio cutting in and out, or dashboard lights flickering, it could be a sign of a wire harness issue.

- Engine misfiring or stalling: When the wire harness is damaged, it can cause miscommunication between the engine control unit (ECU) and various components, leading to engine misfires or even stalling.

- Inconsistent sensor readings: Faulty wiring can interfere with proper sensor readings, resulting in erratic behavior or inaccurate data from sensors like the oxygen sensor or throttle position sensor.

- Malfunctioning warning lights: If your vehicle’s warning lights, such as the check engine light or ABS light, keep turning on without any apparent reason, it may indicate a wire harness issue affecting the communication with the ECU.

- Problems with electronic accessories: Issues with electronic accessories like the power locks, power seats, or climate control system could be a result of a wire harness failure disrupting the electrical signals.

Now that you are aware of the possible symptoms, you may wonder how to determine if the CAN bus connector is the source of the issue. Here are a few steps to help you identify the problem:

- Perform a visual inspection: Inspect the wire harness and connectors for any visible signs of damage, such as frayed wires, burnt insulation, or loose connections. If you spot any issues, it is likely that the CAN bus connector is the culprit.

- Check for error codes: Use an OBD-II scanner to retrieve any trouble codes stored in the vehicle’s computer system. If you come across codes related to the CAN bus or communication errors, there is a high chance that the wire harness, including the CAN bus connector, is problematic.

- Test connectivity: Use a multimeter or continuity tester to check for proper continuity in the wire harness. If there are interruptions or inconsistent readings, it indicates a wiring issue, potentially involving the CAN bus connector.

Keep in mind that diagnosing wire harness failure and identifying the root cause can be challenging. If you are unsure or lack the expertise, it is advisable to consult a professional automotive technician who can efficiently diagnose the issue and recommend the appropriate repair or replacement.

Repairing the Wire Harness- Step-by-step guide on repairing the wire harness- Tools and materials required for the repair process- Troubleshooting tips for resolving any connectivity issues

Repairing a wire harness is a crucial process to ensure the smooth functioning of your vehicle’s electrical system. Here is a step-by-step guide to help you navigate through the repair process and get your wire harness back in working order.

Step 1: Identify the damaged wires

Inspect the wire harness carefully to identify any damaged or broken wires. Look for any signs of fraying, cuts, or exposed copper. Identify the specific wires that need repair.

Step 2: Gather the necessary tools and materials

Before starting the repair, make sure you have all the required tools and materials. This includes wire strippers, electrical tape, heat shrink tubing, a soldering iron, and solder.

Step 3: Cut and strip the damaged wires

Cut the damaged section of the wire to remove any frayed or broken ends. Use wire strippers to strip off a small section of insulation from each end of the wire.

Step 4: Clean the wire ends

Using a wire brush or sandpaper, clean the exposed copper ends of the wires. This helps remove any corrosion or dirt that may affect the quality of the connection.

Step 5: Solder the wires

Heat the soldering iron and apply a small amount of solder to the cleaned wire ends. Hold the wire ends together and touch the soldering iron to the joint until the solder melts and creates a solid connection.

Step 6: Insulate the repaired wires

Slide a piece of heat shrink tubing over the repaired section of the wire. Use a heat gun to shrink the tubing and create a secure and insulated covering over the soldered joint.

Step 7: Wrap the repaired area with electrical tape

After the heat shrink tubing has cooled down, wrap the entire repaired area with electrical tape. This provides an additional layer of protection and helps secure the wires in place.

Troubleshooting Tips:

-

If you encounter any connectivity issues after the repair, double-check the soldered joints and ensure they are secure.

-

Inspect adjacent wires for any signs of damage or wear, as they might also need repair.

-

If you are unsure about any step in the repair process, consult a professional or refer to the vehicle’s repair manual.

By following this step-by-step guide and utilizing the necessary tools and materials, you can effectively repair a wire harness and restore the proper functioning of your vehicle’s electrical system. Remember to exercise caution and take your time during the process to ensure a successful repair.

Replacing the Can Bus Connector

When it comes to addressing wire harness failure in your 2009 Chrysler T&C, replacing the can bus connector may be necessary. This crucial component plays a vital role in transmitting data signals throughout the vehicle’s electrical system. Here are some detailed instructions to help you effectively replace the can bus connector:

1. Gather the Necessary Tools and Materials: Before starting the replacement process, make sure you have the required tools and materials handy. You will need a set of screwdrivers, wire cutters, wire strippers, electrical tape, and a replacement can bus connector compatible with the 2009 Chrysler T&C.

2. Disconnect the Battery: Begin by disconnecting the negative terminal of the vehicle’s battery to prevent any electrical accidents or surges during the replacement process. This step ensures your safety and protects the electrical components of the vehicle.

3. Locate the Faulty Can Bus Connector: Identify the location of the faulty can bus connector in your 2009 Chrysler T&C. It is typically found near the center console or under the dashboard. Remove any covers or panels obstructing access to the connector.

4. Disconnect the Wiring Harness: Carefully disconnect the wiring harness connected to the faulty can bus connector. Take note of the wire connections and their respective positions to ensure proper reassembly later on. Use a screwdriver or appropriate tool to release any locking mechanisms or clips holding the connector in place.

5. Remove the Old Can Bus Connector: Once the wiring harness is disconnected, you can proceed to remove the old can bus connector. Depending on the connector type, there may be screws or clips securing it to the vehicle. Use caution and gentle force to avoid damaging any surrounding components.

6. Install the New Can Bus Connector: Position the replacement can bus connector in the designated location. Ensure it is aligned correctly and secure it using the screws or clips from the previous step. Take care not to overtighten the screws to prevent damage.

7. Connect the Wiring Harness: Reconnect the wiring harness to the new can bus connector, matching the wire connections as noted earlier. Use the appropriate locking mechanisms or clips to ensure a secure connection. Double-check that all connections are stable and properly seated.

8. Reconnect the Battery and Test: Once the replacement is complete, reconnect the negative terminal of the vehicle’s battery. This will restore power to the electrical system. Test the functionality of the replaced can bus connector by checking if all relevant systems and features are working properly.

Precautions to Take During the Replacement Process:

- Always exercise caution when working with electrical components to avoid injury or damage.

- Follow the manufacturer’s instructions for the replacement can bus connector to ensure compatibility and proper installation.

- Handle the wiring harness and connectors with care to avoid damaging delicate wires or connections.

- Double-check all connections and ensure they are secure before reassembling any panels or covers.

- If you are unsure about any step or encounter difficulties, it is advisable to seek professional assistance.

By following these detailed instructions and taking the necessary precautions, you can confidently replace the can bus connector in your 2009 Chrysler T&C. Remember to prioritize safety and consult professional help if needed. Properly addressing wire harness failure will help ensure the reliable performance of your vehicle’s electrical system.

Conclusion

In conclusion, the failure of the wire harness in the 2009 Chrysler Town & Country can be a frustrating issue to deal with. However, there are solutions available to repair or replace a CAN bus connector. It is important to diagnose the problem accurately and seek professional help if needed, as working with electrical systems can be complex and potentially dangerous.

When it comes to repairing the wire harness, you may be able to fix it yourself by identifying the damaged wires and using appropriate tools to splice and reconnect them. However, if the damage is extensive or you’re not confident in your abilities, it is best to consult a skilled technician or an automotive electrician.

If a replacement is necessary, you can purchase a new wire harness or a CAN bus connector from reputable online retailers or auto parts stores. Make sure to choose the correct model and ensure compatibility with your vehicle’s make and model. Remember to follow the manufacturer’s instructions and take proper safety precautions when installing the new component.

By addressing the wire harness failure promptly and taking the necessary steps to repair or replace it, you can restore the functionality of your 2009 Chrysler Town & Country and continue to enjoy a reliable and safe driving experience.

FAQs

1. What is a wire harness?

A wire harness, also known as a wiring harness or cable assembly, is a collection of wires, cables, and connectors that are bundled together to transmit electrical power and signals between various components in a vehicle.

2. What is a CAN bus connector?

A CAN bus connector, or Controller Area Network bus connector, is a specialized connector used in vehicles to connect the various electronic components and modules to the CAN bus network. The CAN bus allows for communication between different systems, such as the engine control module, transmission control module, and body control module.

3. What causes wire harness failure in a 2009 Chrysler T&C?

Wire harness failure in a 2009 Chrysler Town & Country (T&C) can be caused by a variety of factors, including wear and tear, exposure to extreme temperatures, physical damage, and electrical problems. Over time, the wires in the harness can become corroded, frayed, or disconnected, resulting in loss of electrical connectivity and malfunctioning of the connected components.

4. How can I repair a wire harness in a 2009 Chrysler T&C?

Repairing a wire harness in a 2009 Chrysler T&C depends on the extent of the damage. If the issue is localized to a specific area, you may be able to splice or solder the damaged wires back together. However, for more severe damage or extensive wear, it may be necessary to replace the entire wire harness with a new one.

5. Can I replace a CAN bus connector myself?

Replacing a CAN bus connector in a 2009 Chrysler T&C can be a complex task, as it requires knowledge of vehicle electrical systems and proper wiring techniques. It is recommended to consult a professional automotive technician who has experience in handling wire harness repairs and replacements. They will have the necessary tools and expertise to ensure a proper installation and avoid any potential damage to the vehicle’s electrical system.