Welcome to our comprehensive guide on terminal connectors! If you’re new to the world of electrical or electronic circuits, you might be wondering what exactly a terminal connector is and why it’s so important. Put simply, a terminal connector is a device or component used to establish a secure and reliable connection between two or more conductors. It acts as a bridge, ensuring that electrical signals can flow seamlessly between different components or devices. Whether you’re working on a DIY project or a professional installation, understanding how terminal connectors work and their different types is essential. In this guide, we’ll delve into the basics of terminal connectors, explore the various types available, and provide practical tips for choosing and using them effectively. So, let’s dive in and unlock the world of terminal connectors together!

Inside This Article

- Terminal Connector Basics

- Common Types of Terminal Connectors

- Factors to Consider When Choosing Terminal Connectors

- Proper Installation and Maintenance of Terminal Connectors

- Applications of Terminal Connectors

- Conclusion

- FAQs

Terminal Connector Basics

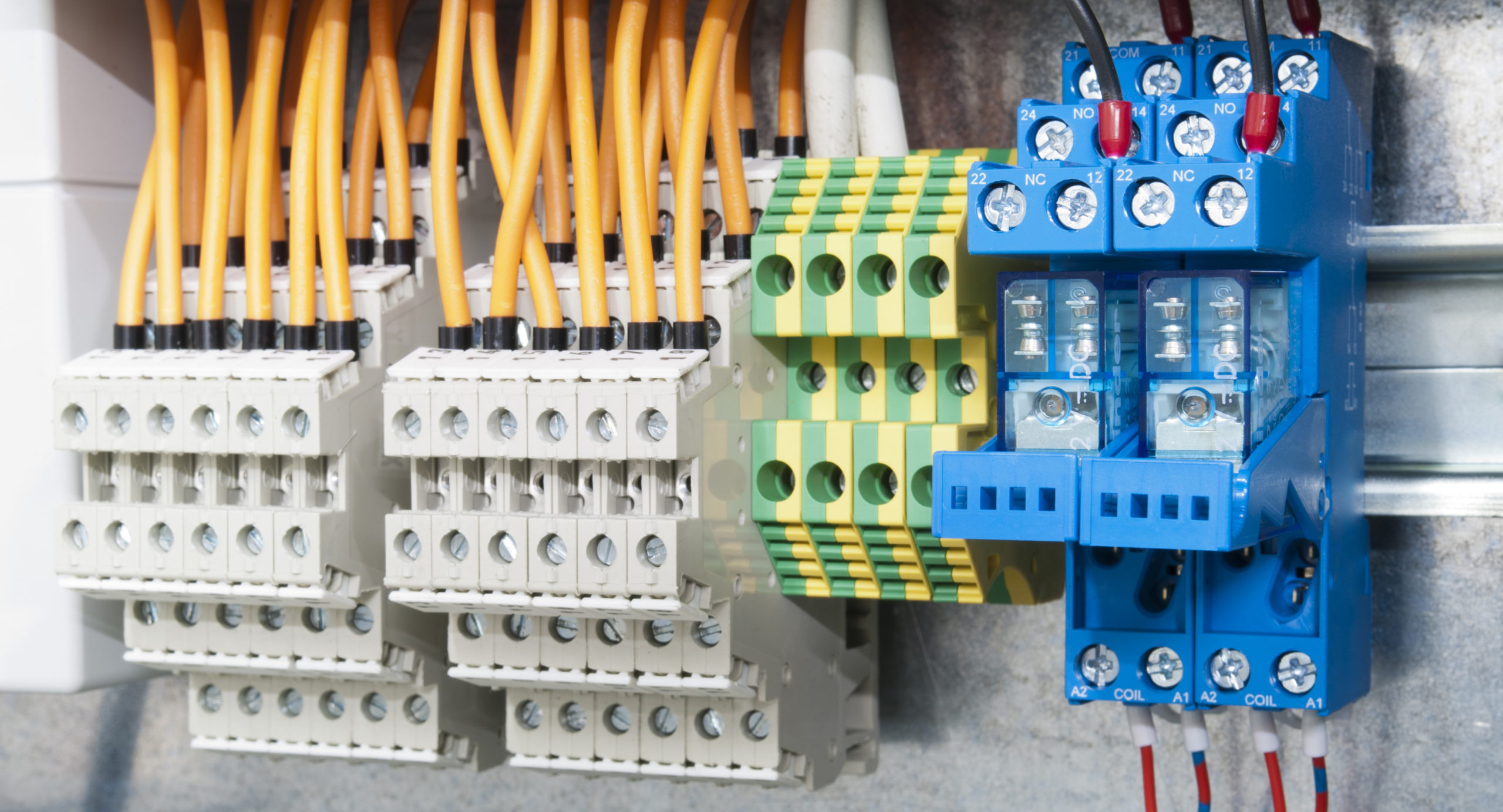

A terminal connector is a crucial component in electrical systems that allows the secure and reliable connection of wires or cables. It is designed to join two or more wires together and provide a seamless flow of electrical current.

The primary purpose of a terminal connector is to ensure a secure and stable connection between wires, preventing them from becoming loose or disconnected. This is particularly important in electrical systems where the integrity of the wiring is crucial.

There are various types of terminal connectors available, each designed to fulfill specific functions and accommodate different wire sizes and configurations. These connectors play a vital role in the proper functioning of electrical systems and are widely used in automotive, residential, commercial, and industrial applications.

Types of Terminal Connectors

1. Spade Connectors: These connectors feature a flat, blade-like design with a hole or crimping sleeve at the end. They are commonly used in automotive applications and are easy to install and remove.

2. Ring Terminals: As the name suggests, ring terminals have a circular shape with a hole in the center. They are mostly used for connecting wires to studs or screws and are commonly found in electrical panels and motor control centers.

3. Butt Connectors: Butt connectors are used to splice two wires together end-to-end. They consist of a metal tube with insulation that is crimped onto the wires, providing a secure and insulated connection.

4. Bullet Connectors: Bullet connectors are cylindrical in shape and have a male and female end. They are commonly used in automotive wiring for connecting wires to components such as headlights and taillights.

Importance of Terminal Connectors in Electrical Systems

Terminal connectors play a crucial role in ensuring the integrity and reliability of electrical systems. They provide a secure and stable connection that prevents wires from coming loose or getting disconnected due to vibrations, temperature fluctuations, or other external factors.

Moreover, terminal connectors also provide insulation and protection to the wires, safeguarding them against moisture, dust, and other contaminants. This helps to maintain the efficiency and longevity of the electrical system.

In addition, terminal connectors make it easier to install, repair, or replace components in the electrical system without the need for re-wiring. This not only saves time and effort but also minimizes the risk of damage to the wires.

Overall, terminal connectors are essential components in electrical systems, ensuring proper electrical conductivity, stability, and protection. Whether it’s in automotive vehicles, residential buildings, industrial equipment, or electronic devices, terminal connectors provide the necessary connections for seamless electrical transmission.

Common Types of Terminal Connectors

When it comes to electrical connections, terminal connectors play a vital role in ensuring secure and reliable connections. There are several common types of terminal connectors available, each with its unique design and functionality. Let’s explore some of the most commonly used types:

1. Spade Connectors: Spade connectors, also known as fork terminals, feature a flat, U-shaped metal piece that allows for easy insertion and removal from screw terminals or binding posts. They are commonly used in automotive and electrical applications and are available in various sizes to accommodate different wire gauges.

2. Ring Terminals: Ring terminals, as the name suggests, have a circular shape with a hole in the center. They are commonly used in applications where a secure connection is required, such as in automotive battery terminals or circuit breaker connections. Ring terminals are available in different sizes to fit specific stud or screw sizes.

3. Butt Connectors: Butt connectors are used to join two wires together end-to-end, providing a reliable and insulated connection. They are often used in automotive and electrical applications, as well as in audio installations. Butt connectors can be crimped or soldered to ensure a secure connection, and they come in different colors to indicate wire gauge sizes.

4. Bullet Connectors: Bullet connectors, also known as bullet terminals, have a cylindrical shape and are used for quick and easy connections. They are commonly found in automotive applications, particularly for connecting wires to components like headlights or turn signals. Bullet connectors feature a male and female end, allowing for easy and secure connections.

These common types of terminal connectors offer versatility and reliability in various electrical applications. It is essential to choose the appropriate type of connector based on the specific requirements of your project to ensure a secure and long-lasting connection.

Factors to Consider When Choosing Terminal Connectors

When it comes to selecting terminal connectors for your electrical system, there are several essential factors to consider. These factors play a crucial role in ensuring the effectiveness, safety, and reliability of your electrical connections. Let’s explore each of these factors in detail:

1. Wire Size and Compatibility: One of the most important factors to consider when choosing terminal connectors is the compatibility with the wire size. Terminal connectors are available in different sizes to accommodate various wire gauges. It is crucial to select connectors that are specifically designed for the wire size you are using. This ensures a secure and reliable connection, minimizing the risk of loose or unstable connections.

2. Electrical Current Capacity: Another vital factor to consider is the electrical current capacity of the terminal connectors. Different connectors have varying current-carrying capacities, and it is essential to select connectors that can handle the expected current flow in your system. Using connectors with inadequate current capacity can lead to overheating, voltage drops, and potential failure of the electrical circuit.

3. Insulation and Protection: Terminal connectors should provide adequate insulation and protection to prevent accidental contact with live parts, reduce the risk of electrical arcing, and protect against environmental factors such as moisture, dust, and vibration. Look for connectors with insulation sleeves or coatings that comply with industry standards for electrical safety.

4. Ease of Installation: The ease of installation is an important consideration, especially if you have multiple connections to make or if you frequently need to make changes or additions to your electrical system. Choose connectors that are easy to handle, have clear installation instructions, and require minimal tools or specialized equipment. This will help save time and effort during installation and maintenance tasks.

By considering these factors when selecting terminal connectors, you can ensure reliable and safe electrical connections in your system. It is always recommended to consult with a knowledgeable professional or refer to industry standards and guidelines for specific applications to ensure you choose the right connectors for your needs.

Proper Installation and Maintenance of Terminal Connectors

Proper installation and maintenance of terminal connectors are crucial for ensuring the efficient and reliable performance of electrical systems. Whether you are working on automotive wiring, electrical wiring in buildings, or industrial machinery, following a step-by-step guide and avoiding common mistakes are essential. Additionally, regular inspection and maintenance play a vital role in prolonging the lifespan of terminal connectors and preventing potential issues.

Step-by-step Guide for Installing Terminal Connectors

When installing terminal connectors, following a systematic approach is essential to ensure secure and efficient connections. Here is a step-by-step guide to help you with the installation process:

- Prepare the wires: Strip the insulation from the end of the wires, making sure to expose enough copper for a secure connection. If necessary, use a wire stripper to ensure a clean and precise strip.

- Select the appropriate terminal connector: Choose a terminal connector that matches the wire size and type, ensuring a proper fit.

- Insert the wire into the terminal connector: Insert the stripped end of the wire into the terminal connector, ensuring that it is fully inserted.

- Crimp the terminal connector: Using a crimping tool, apply sufficient pressure to securely crimp the terminal connector onto the wire. This will create a tight and reliable connection.

- Inspect the connection: After crimping, visually inspect the connection to ensure that it is secure and there are no loose wires or exposed conductors.

Following these steps will help ensure a proper and reliable installation of terminal connectors, reducing the risk of electrical failures or malfunctions.

Common Mistakes to Avoid

While installing terminal connectors, it is crucial to avoid common mistakes that can compromise the integrity of the connection. Here are a few mistakes to be aware of:

- Inadequate stripping: Failing to strip the wire properly can result in a weak connection or poor conductivity. Ensure that the insulation is stripped adequately, exposing enough copper for a secure and reliable connection.

- Improper crimping: Insufficient pressure or using the wrong crimping tool can result in a loose connection. It is important to apply the correct amount of pressure during the crimping process to ensure a tight and reliable connection.

- Using incorrect terminal connectors: Choosing the wrong type or size of terminal connector can lead to compatibility issues and weak connections. Always select a terminal connector that matches the wire size and type for a secure and reliable connection.

- Ignoring insulation and protection: Neglecting to provide proper insulation and protection for the terminal connection can lead to potential hazards, such as short circuits or electrical shocks. Ensure that the connection is adequately insulated and protected to prevent such risks.

By avoiding these common mistakes, you can ensure a proper and reliable installation of terminal connectors, minimizing the risk of electrical issues and system failures.

Importance of Regular Inspection and Maintenance

Regular inspection and maintenance are essential for maintaining the integrity and performance of terminal connectors. Over time, factors such as vibrations, temperature fluctuations, and environmental conditions can impact the connection and potentially lead to issues. Regularly inspecting terminal connectors helps identify any signs of damage, corrosion, or looseness.

Inspecting terminal connectors should include checking for loose or exposed wires, signs of overheating, corrosion, and damage to the insulation. If any issues are detected, they should be addressed immediately to prevent further complications.

In addition to regular inspection, regular maintenance practices should be adopted. This may include tightening loose connections, cleaning corroded terminals, and applying protective coatings or insulating materials when necessary. By conducting regular inspections and maintenance, you can extend the lifespan of your terminal connectors, enhance the reliability of electrical systems, and minimize the risk of potential failures.

Applications of Terminal Connectors

Terminal connectors play a crucial role in various industries and applications. Let’s explore some of the key areas where terminal connectors are widely used:

Automotive and Vehicle Wiring

In the automotive industry, terminal connectors are essential for electrical connections in vehicles. From the simplest wiring tasks, such as connecting wires to headlights or tail lights, to more complex tasks involving the wiring of engine components, terminal connectors ensure a reliable and secure connection. These connectors help to maintain the integrity of the electrical system in vehicles, ensuring proper functioning of critical components such as ignition systems, sensors, and fuel injectors.

Electrical Wiring in Buildings

Terminal connectors are widely used in electrical wiring systems in buildings, including residential, commercial, and industrial constructions. These connectors facilitate the connection of wires to various electrical components, such as outlets, switches, and circuit breakers. They ensure proper electrical conductivity, preventing loose or faulty connections that could lead to malfunctions or electrical hazards. Terminal connectors provide a convenient and efficient solution for maintaining the electrical infrastructure of buildings.

Industrial Machinery and Equipment

In industrial settings, terminal connectors are utilized in machinery and equipment for interconnecting electrical components. Whether it’s heavy machinery in manufacturing plants or control panels in automation systems, terminal connectors provide a secure and efficient way to connect wires, cables, and components. These connectors are designed to withstand harsh operating conditions, such as high temperatures, vibrations, and electrical currents, ensuring reliable and long-lasting connections in industrial environments.

Electronics and Telecommunications

Terminal connectors are extensively used in the electronics and telecommunications industry. They play a crucial role in connecting wires to circuit boards, connectors, and various electronic devices. Whether it’s smartphones, computers, or communication systems, terminal connectors enable efficient and reliable electrical connections, ensuring proper functionality and signal transmission. The compact size and versatility of terminal connectors make them ideal for high-density electronic applications and the ever-evolving field of telecommunications.

Overall, terminal connectors are vital components in automotive, building, industrial, and electronics applications. They provide secure and efficient electrical connections, contributing to the stability, functionality, and safety of various systems and equipment.

Conclusion

Terminal connectors play a vital role in various industries and applications, from electrical systems to telecommunications. These small yet powerful components provide a secure and reliable connection between wires, ensuring the smooth flow of electrical signals. With their versatility and durability, they have become an essential part of our technological advancements.

Whether you’re setting up a new wiring system or need to repair existing connections, understanding terminal connectors is crucial. From ring terminals to spade terminals and everything in between, each type has its unique features and application. By choosing the right terminal connector for your specific needs, you can ensure a high-quality and long-lasting connection.

From automotive repairs to home DIY projects, terminal connectors are an invaluable accessory that simplifies electrical connections. Their design and functionality make them user-friendly and efficient, providing a seamless experience for both professionals and enthusiasts.

So, next time you’re in need of a secure electrical connection, don’t overlook the importance of terminal connectors. With their wide range of options and applications, they are an essential accessory for any electrical project.

FAQs

FAQ 1: What is a terminal connector?

A terminal connector is a device used to connect or terminate electrical wires or cables to another piece of equipment or a power source. It acts as a bridge between the wires or cables and the equipment, allowing for a secure and reliable electrical connection.

FAQ 2: What are the types of terminal connectors?

There are various types of terminal connectors available, each designed for specific applications. Some commonly used terminal connector types include ring terminals, spade terminals, bullet terminals, butt connectors, and quick-disconnect connectors.

FAQ 3: How do terminal connectors work?

Terminal connectors typically consist of a metal or plastic body with a hole or slot to insert the wire or cable. The wire is secured in place using a screw, crimping mechanism, or insulation displacement. The connector is then connected to the equipment or power source, ensuring a reliable and stable electrical connection.

FAQ 4: What are the advantages of using terminal connectors?

Terminal connectors offer several advantages in electrical wiring and connections. They provide a secure and reliable connection, minimizing the risk of accidental disconnection. Terminal connectors also allow for easy installation and removal of wires or cables when needed. Furthermore, they provide insulation and protection against moisture, dust, and other environmental factors, ensuring the longevity and reliability of the electrical connection.

FAQ 5: Where are terminal connectors commonly used?

Terminal connectors are widely used in various industries and applications. They are commonly found in automotive wiring, electrical devices, appliances, industrial equipment, and power distribution systems. Terminal connectors are essential for creating reliable and efficient electrical connections in these applications.