Are you interested in learning how to read a forklift data plate? Look no further, as this comprehensive guide will walk you through the process step by step. When operating or maintaining a forklift, it is crucial to understand the information provided on its data plate. The data plate contains important details about the forklift’s specifications and capabilities, ensuring safe and efficient operation. From load capacities to battery requirements, serial numbers to manufacturer information, each element on the data plate serves a specific purpose. By mastering the art of reading a forklift data plate, you can make informed decisions, maintain compliance with safety regulations, and operate the forklift with confidence. So, get ready to delve into the world of forklift data plates and unlock a plethora of valuable information.

Inside This Article

- Overview of a Forklift Data Plate

- Understanding the Information on a Forklift Data Plate

- Key Details Provided on a Forklift Data Plate

- Interpreting the Specifications on a Forklift Data Plate

- Conclusion

- FAQs

Overview of a Forklift Data Plate

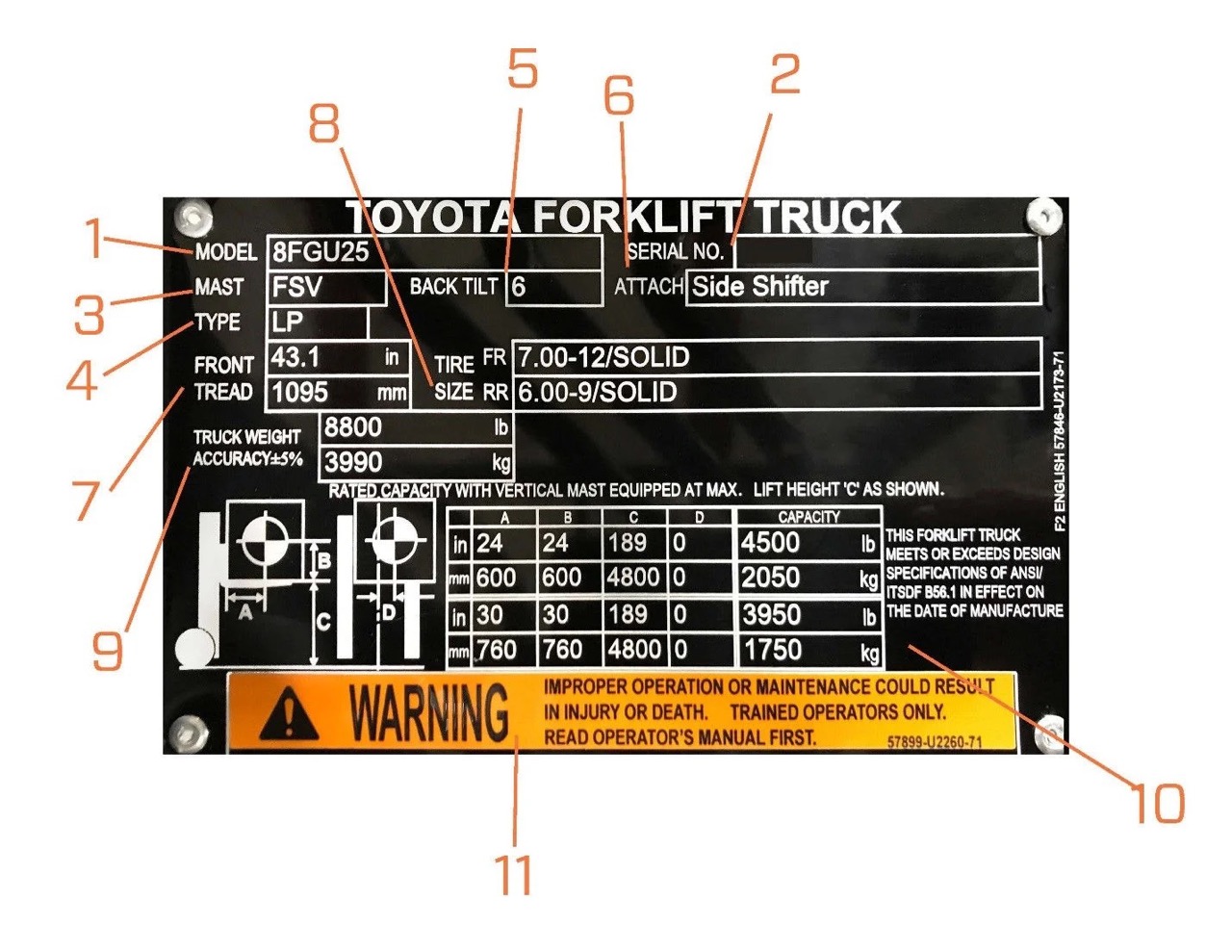

A forklift data plate, also known as a forklift nameplate or forklift capacity plate, is a crucial component that provides important information about a forklift. This small metal tag is usually located in the operator’s compartment or affixed to the forklift’s frame. The data plate serves as a quick reference guide for operators, technicians, and inspectors to understand the capabilities and limitations of the forklift.

The purpose of a forklift data plate is to ensure safety and compliance with industry regulations. It contains essential details about the forklift’s make, model, serial number, production date, and manufacturer. Additionally, it provides information such as the maximum load capacity, lift height, and other specifications specific to the particular forklift.

By referring to the forklift data plate, operators can understand the weight limits and safe operating conditions for the forklift. It helps them determine the maximum load that the forklift can safely carry and the maximum lifting height that it is designed to reach. This information is essential for preventing accidents, avoiding overloading the forklift, and maintaining optimal performance.

Furthermore, the forklift data plate may also include additional details, such as tire type and pressure requirements, fuel or power source, brake specifications, and any special equipment attachments that are compatible with the forklift. This information enables operators to ensure that the forklift is operated correctly, maintained properly, and equipped with the appropriate accessories for different tasks.

Understanding the Information on a Forklift Data Plate

When operating a forklift, it is essential to understand the information displayed on the forklift data plate. This small metal plate, usually located on the forklift’s dashboard or frame, contains crucial details about the forklift’s specifications and capabilities. By decoding the information on the data plate, operators can ensure they are operating the forklift safely and efficiently.

The forklift data plate typically includes important information such as the forklift’s maximum weight capacity, load center, mast type, lift height, and more. Let’s take a closer look at each of these key details:

1. Maximum Weight Capacity: This indicates the maximum weight that the forklift is designed to lift. It is crucial to adhere to this limit to prevent overloading the forklift, which can lead to instability and accidents.

2. Load Center: The load center refers to the horizontal distance between the center of the load and the forklift’s front wheels. This information is crucial for determining the forklift’s stability and load capacity.

3. Mast Type: The mast, also known as the upright assembly, is responsible for lifting and lowering the load. The data plate will indicate the type of mast the forklift is equipped with, such as a standard mast, triple mast, or quad mast.

4. Lift Height: The lift height refers to the maximum vertical distance that the forklift’s mast can extend. It is important to know this information to ensure that the forklift can reach the desired height for stacking or unloading.

5. Tire Type: The data plate may also specify the type of tires installed on the forklift, whether they are pneumatic (air-filled), cushion, or solid rubber tires. This information is crucial for determining the forklift’s suitability for different operating conditions or surfaces.

6. Fuel Type: The data plate will indicate whether the forklift is powered by electricity, gasoline, diesel, or other sources. This information is essential for proper fueling and maintenance of the forklift.

Understanding the information on a forklift data plate is not only essential for operators but also for supervisors and those responsible for forklift maintenance. This knowledge ensures that the forklift is used within its design limits and helps prevent accidents caused by improper use or overloading.

By referring to the data plate and understanding the specifications, operators can make informed decisions regarding load capacity, lifting height, and other crucial factors, promoting safety and efficiency in the workplace.

Key Details Provided on a Forklift Data Plate

When operating a forklift, it’s essential to understand the key details provided on the forklift data plate. This plate contains crucial information about the specifications and capabilities of the forklift, ensuring safe and efficient operation. Let’s explore the key details that you can find on a forklift data plate.

1. Forklift Model: The data plate will typically include the forklift model information. This helps in identifying the specific type and model of the forklift you are operating. It is important to be aware of the model to ensure you are using the correct operating procedures and safety guidelines.

2. Maximum Load Capacity: The data plate will list the maximum load capacity of the forklift. This indicates the maximum weight that the forklift is designed to lift safely. It is crucial to adhere to this limit to prevent accidents, maintain stability, and ensure the longevity of the forklift.

3. Lifting Height: Another important detail on the data plate is the maximum lifting height of the forklift. This specifies how high the forklift can safely lift a load. It is essential to consider this when operating in warehouses or areas with limited vertical clearance to avoid damage to the forklift or overhead obstacles.

4. Fork Length: The data plate will also include the length of the forks attached to the forklift. This measurement is crucial for selecting the appropriate pallets or loads that can be safely carried by the forklift. Using forks that are too short or too long can lead to instability and potential accidents.

5. Power Source: The data plate will specify the power source of the forklift, whether it is electric, gasoline, diesel, or propane. Knowing the power source is important for understanding the appropriate refueling or recharging procedures and safety precautions.

6. Tire Type: The data plate will indicate the type of tires fitted on the forklift, such as pneumatic or solid tires. This information is crucial for determining the appropriate terrain on which the forklift can be safely operated. Different tire types are designed for specific surfaces, and operating the forklift on the wrong surface can compromise stability and safety.

7. Weight of the Forklift: The data plate will list the weight of the forklift itself. Understanding the weight is important for ensuring that the forklift is operated within its designed capacity. Overloading the forklift beyond its weight limit can lead to instability and potential damage to the machine.

8. Manufacturer Information: The data plate will include the manufacturer’s information, such as the name, contact details, and sometimes the manufacturing date. This information is useful for contacting the manufacturer in case of any inquiries, maintenance needs, or safety concerns.

By familiarizing yourself with the key details provided on a forklift data plate, you can ensure safe and efficient operation of the forklift. Always consult the data plate and follow the manufacturer’s guidelines and safety procedures to prevent accidents and maintain the longevity of the forklift.

Interpreting the Specifications on a Forklift Data Plate

When it comes to operating a forklift safely and efficiently, it’s essential to understand the specifications listed on its data plate. This crucial piece of information provides valuable details about the forklift’s capabilities and limitations. By interpreting these specifications correctly, you can ensure that you are operating the forklift within its intended parameters, minimizing the risk of accidents and maximizing productivity.

Let’s take a closer look at the key specifications you’ll typically find on a forklift data plate:

- Maximum Load Capacity: The maximum load capacity indicates the maximum weight the forklift can safely lift and carry. It’s important to never exceed this limit, as overloading the forklift can result in instability and potential accidents.

- Lift Height: The lift height specifies the maximum height to which the forklift is designed to lift loads. It is essential to consider this specification when working in areas with low ceilings or tight spaces to ensure that the forklift can operate safely without any height restrictions.

- Overall Dimensions: The overall dimensions provide information about the length, width, and height of the forklift. These measurements are crucial for determining whether the forklift can maneuver through doorways, around tight corners, and fit in designated storage spaces.

- Tire Type: The tire type indicates the type of tires fitted on the forklift, such as pneumatic, solid, or cushion. Understanding the tire type is essential for determining the appropriate forklift for specific operating environments, such as rough terrains or indoor warehouse settings.

- Fuel Type or Power Source: The fuel type or power source specifies whether the forklift runs on diesel, electric, LPG, or other fuels. Knowing the forklift’s power source is essential for maintenance, refueling, and ensuring compatibility with the available infrastructure.

- Turning Radius: The turning radius refers to the minimum space required for the forklift to make a full 360-degree turn. This specification is especially important in congested areas or narrow aisles, ensuring that the forklift can maneuver safely and efficiently without causing damage or disruptions.

- Operating Weight: The operating weight indicates the weight of the forklift itself, including any accessories or attachments. It is crucial to consider the operating weight when determining the load capacity and ensuring the forklift is suitable for the designated work environment.

- Serial Number: The serial number is a unique identifier that helps track the forklift’s manufacturing details, including the year of production and any specific modifications or features. It is essential for reference purposes, such as ordering replacement parts or verifying warranty information.

By interpreting and understanding the specifications on a forklift data plate, operators can ensure safe and efficient operation while complying with industry regulations. It is crucial to consult the forklift’s manual or seek expert guidance if any specifications are unclear or require further clarification. Prioritizing safety and adhering to the manufacturer’s guidelines is paramount when operating a forklift.

Conclusion

Understanding how to read a forklift data plate is essential for operators, technicians, and safety personnel working with forklifts. This small metal plate provides crucial information about the forklift’s specifications, capabilities, and safety requirements.

By deciphering the data plate, operators can ensure they are using the forklift within its prescribed limits, preventing accidents and maximizing efficiency. Technicians can use the information to perform maintenance, repairs, and inspections accurately and safely. Safety personnel can verify that the forklift’s operating conditions meet the necessary standards and take appropriate measures when necessary.

Whether you’re operating a forklift or responsible for its maintenance, gaining competency in interpreting the data plate is a valuable skill. It allows for the safe and efficient operation of the forklift, contributing to a productive and secure work environment.

So remember, next time you encounter a forklift data plate, take the time to read and understand its contents. It’s a small effort that can make a big difference in the safe and effective operation of forklifts in any setting.

FAQs

Q: What is a forklift data plate?

A: A forklift data plate, also known as a forklift nameplate or data tag, is a metal or plastic plate that contains important information about a forklift, such as its model, serial number, load capacity, and other specifications.

Q: Why is it important to read a forklift data plate?

A: Reading a forklift data plate is crucial because it provides essential information about the forklift, ensuring that it is used safely and in accordance with its specifications. It helps operators and supervisors understand its capabilities, load capacities, maintenance requirements, and other important details.

Q: Where can I find the forklift data plate?

A: The forklift data plate is usually located on the forklift itself, typically affixed to the chassis near the operator’s seat or the engine compartment. It may also be found on the inside of the driver’s side door or on the overhead guard.

Q: What information does a forklift data plate provide?

A: A forklift data plate provides vital information, including the manufacturer’s name and contact information, the model name or number, the serial number, the year of manufacture, the load capacity, the mast type, the tire type, the fuel or power source, and any additional specifications or safety instructions.

Q: How can I interpret the information on a forklift data plate?

A: To interpret the information on a forklift data plate, you can refer to the forklift’s user manual or contact the manufacturer. They can explain the meaning of the various codes and specifications listed on the plate and provide guidance on any specific requirements or restrictions.