When it comes to fiber optic connector end face inspection, having a relevant standard is crucial. The quality and cleanliness of the end face are vital for ensuring optimal performance and reducing signal loss in fiber optic connections. But with various standards and specifications in the market, it can be challenging to determine which one is the most applicable.

In this article, we will delve into the question of which standard is the most relevant for fiber optic connector end face inspection. We will explore the different standards available, their requirements, and their importance in maintaining the integrity of fiber optic connections. Whether you are a technician, installer, or someone interested in understanding more about fiber optic technology, this article aims to provide you with the necessary insights to make informed decisions and ensure the proper inspection of fiber optic connector end faces.

Inside This Article

- Overview of Fiber Optic Connector End Face Inspection

- ANSI/TIA-568-C.3 Standard

- IEC 61300-3-35 Standard

- Comparison Between ANSI/TIA-568-C.3 and IEC 61300-3-35 Standards

- Conclusion

- FAQs

Overview of Fiber Optic Connector End Face Inspection

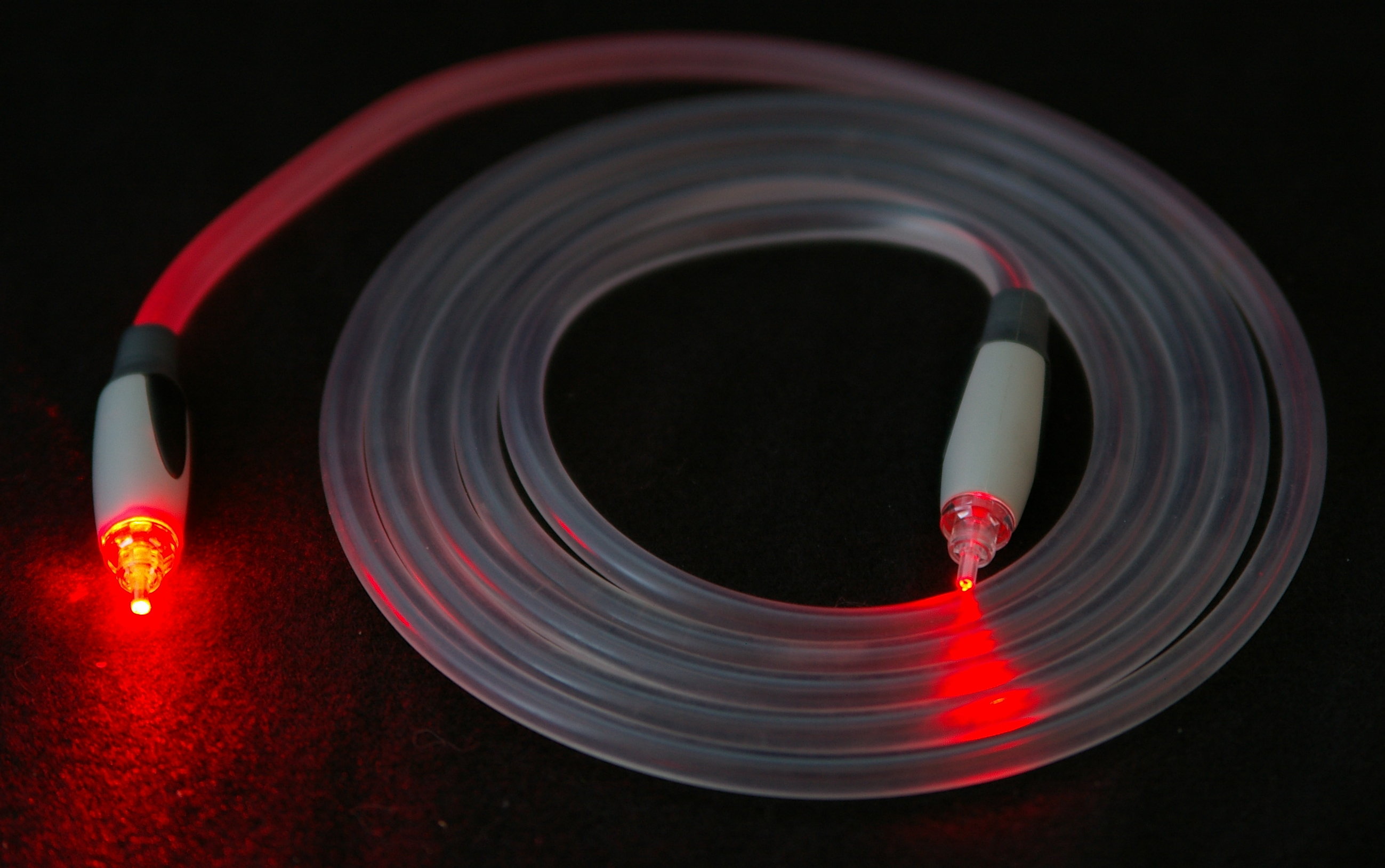

Fiber optic connectors play a crucial role in ensuring seamless and efficient communication in the world of telecommunications. The end face of a fiber optic connector is the most critical component, as it directly affects the performance and quality of the connection. Proper inspection and maintenance of the end face are essential to prevent signal loss, insertion loss, and potential damage to the connector.

Fiber optic connector end face inspection involves the evaluation of the connector’s surface to identify any dirt, scratches, or other contaminants that may affect signal transmission. By conducting regular inspections, technicians can detect and address any issues promptly, ensuring optimal performance of the connector and the entire fiber optic network.

Inspecting the end face of a fiber optic connector requires specialized tools and techniques. Visual inspection is the most commonly used method, employing magnification to examine the connector’s surface for any visible defects. It is crucial to use the appropriate magnification level to ensure a thorough inspection.

During the inspection process, technicians should look for various types of contaminants, including dust, dirt, oil, and scratches. These particles can obstruct the light signal and lead to signal degradation or interruptions. Additionally, they should check for any damage to the connector, such as chipped or broken fibers.

To perform a comprehensive inspection, technicians must adhere to industry standards and best practices. These standards define the acceptable levels of cleanliness and the permissible limits for defects on the end face. Following these guidelines ensures the reliability and efficiency of the fiber optic connection.

The inspection process involves the use of inspection microscopes or video fiberscopes, which provide clear and detailed magnified images of the end face. Technicians should carefully clean the connector using lint-free wipes and approved cleaning solutions before conducting the inspection. This step is vital to remove any loose debris or particles that may interfere with the inspection process.

Regular and timely inspection of fiber optic connector end faces is critical to maintain network performance and prevent costly disruptions. By identifying and addressing potential issues promptly, technicians can ensure that the connection operates at its optimal level, minimizing signal loss and improving overall network efficiency.

ANSI/TIA-568-C.3 Standard

The ANSI/TIA-568-C.3 Standard is an important guideline for fiber optic connector end face inspection. This standard was developed by the American National Standards Institute (ANSI) and the Telecommunications Industry Association (TIA). It provides detailed specifications and practices for inspecting and testing fiber optic connector end faces in order to ensure the highest quality of optical connections.

The ANSI/TIA-568-C.3 Standard sets the criteria for acceptable levels of contamination, scratches, and defects on the end face of fiber optic connectors. It defines the permissible limits for various types of contaminants, such as dust particles, oil, fingerprints, and scratches. Adhering to these specifications is crucial to avoid signal loss, interferences, and other performance issues in fiber optic networks.

This standard also specifies the recommended inspection methods and tools for evaluating fiber optic connector end faces. It outlines the general procedures for visual inspection using a fiber optic microscope or video microscope. It also emphasizes the importance of proper cleaning techniques and the use of specialized inspection probes or scopes to accurately assess the condition of the end face.

The ANSI/TIA-568-C.3 Standard is widely recognized and adopted by professionals in the fiber optic industry. Compliance with this standard ensures that fiber optic connector end faces are thoroughly inspected and meet the necessary cleanliness and quality requirements for optimal performance. It establishes a common framework for technicians, installers, and network administrators to achieve consistent and reliable fiber optic connections.

IEC 61300-3-35 Standard

The IEC 61300-3-35 Standard, also known as the International Electrotechnical Commission 61300-3-35, is a widely recognized and essential standard for fiber optic connector end face inspection. It provides guidelines and criteria for the assessment and evaluation of optical connector end faces, ensuring their quality and optimal performance.

One of the key aspects of this standard is the definition and classification of various types of defects that may be found on fiber optic connector end faces. It outlines the acceptable limits for defects such as scratches, pits, contamination, and other imperfections that can negatively impact the performance of the connector.

The IEC 61300-3-35 standard also specifies the equipment and techniques required for proper inspection and evaluation. It emphasizes the use of specialized tools like fiber inspection microscopes and video probes to accurately assess the condition of the connector end face.

Furthermore, this standard establishes clear criteria for determining the severity of defects. It provides guidelines on how to categorize defects based on their size, location, and impact on signal transmission. This helps technicians and inspectors determine whether a connector end face meets the required quality standards for optimal performance.

Compliance with the IEC 61300-3-35 standard is crucial for maintaining the integrity and reliability of fiber optic connections. By adhering to this standard, manufacturers, installers, and service providers can ensure that the connector end faces meet the necessary quality requirements, minimizing the risk of signal loss or degradation.

Comparison Between ANSI/TIA-568-C.3 and IEC 61300-3-35 Standards

When it comes to fiber optic connector end face inspection, two prominent standards are often referred to: ANSI/TIA-568-C.3 and IEC 61300-3-35. Both standards provide guidelines for the inspection and evaluation of fiber optic connector end faces, aimed at ensuring optimal performance and reliability.

The ANSI/TIA-568-C.3 standard, developed by the Telecommunications Industry Association (TIA), covers the requirements for the design and installation of cabling systems. It incorporates specific guidelines for connector end face inspection, focusing on the geometry, cleanliness, and overall quality of the end face. This standard specifies the acceptable levels of scratches, pits, and contaminants on the end face, ensuring that the connector meets the necessary performance criteria.

On the other hand, the IEC 61300-3-35 standard, developed by the International Electrotechnical Commission (IEC), provides a comprehensive framework for the inspection, cleaning, and testing of fiber optic connectors. This standard offers detailed procedures for both visual and instrument-based inspection of the connector end face. It includes specific criteria for evaluating parameters such as scratches, contaminants, and geometric defects, ensuring the reliability and quality of the connection.

While both standards share the common goal of ensuring the proper inspection and evaluation of fiber optic connector end faces, there are some key differences between them. One major difference lies in the specific criteria used to assess the quality of the end face. ANSI/TIA-568-C.3 provides clear guidelines on the acceptable levels of defects, such as scratches and pits, while IEC 61300-3-35 offers more comprehensive criteria for evaluating various parameters, including cleanliness, geometry, and even the presence of epoxy.

Another notable difference is the emphasis on testing methods. ANSI/TIA-568-C.3 primarily focuses on visual inspection techniques, such as using a microscope to examine the end face. In contrast, IEC 61300-3-35 includes provisions for both visual inspection and instrument-based techniques, such as using a video microscope or an automated inspection system. This broader range of testing options in the IEC standard allows for more accurate and detailed evaluation of the connector end face.

It is worth noting that while ANSI/TIA-568-C.3 is widely recognized and used in North America, IEC 61300-3-35 has gained international acceptance. This means that depending on the geographical location and specific requirements of a project, one standard may be more applicable than the other.

Conclusion

In conclusion, selecting the relevant standard for fiber optic connector end face inspection is crucial to ensure the overall performance and reliability of the fiber optic network. When it comes to inspecting end faces, the IEC 61300-3-35 standard has become the industry benchmark due to its comprehensive guidelines and criteria for evaluating the cleanliness and quality of the connector end face. This standard provides a clear framework for technicians and operators to follow, ensuring consistency and accuracy in the inspection process.

By adhering to the IEC 61300-3-35 standard, organizations can minimize the chances of signal degradation, avoid connection issues, and improve the overall efficiency of their fiber optic network. It is important to stay abreast of the latest standards and advancements in fiber optic technology to maintain optimal performance levels. Investing in proper inspection tools and training for technicians is also essential in achieving successful end face inspections.

Ultimately, by following the appropriate standard for end face inspection, organizations can have peace of mind knowing that their fiber optic connectors are clean, reliable, and capable of delivering high-speed data transmission.

FAQs

- What is a fiber optic connector end face inspection?

- Why is fiber optic connector end face inspection important?

- What are the common types of defects found during end face inspections?

- How is fiber optic connector end face inspection performed?

- How often should fiber optic connector end face inspections be conducted?

A fiber optic connector end face inspection is a process used to examine the surface of a fiber optic connector to ensure it is clean, free from defects, and properly aligned. It is crucial to perform this inspection to maintain the optimal performance and reliability of the fiber optic connection.

The cleanliness and condition of a fiber optic connector end face directly impact the quality of the connection. Even small contaminants or defects can lead to signal loss, high insertion loss, or even complete failure of the fiber optic link. Regular inspections help prevent issues, ensure efficient data transmission, and reduce downtime.

Common defects found during fiber optic connector end face inspections include scratches, pits, dirt, dust, oil residue, and chipped or cracked ferrules. These defects can cause signal loss and degrade the performance of the optical network.

Fiber optic connector end face inspection involves the use of specialized tools such as inspection microscopes, fiberscopes, or digital inspection probes. These tools magnify and illuminate the end face, allowing technicians to identify any defects or contaminants. The inspection process typically involves cleaning the end face, examining it under magnification, and documenting the results.

Regular end face inspections are recommended to maintain optimal performance. The frequency of inspections depends on the environmental conditions and usage. In general, inspections should be performed before connecting or reconnecting fiber optic cables, during installation, and periodically as part of routine maintenance.