Are you experiencing issues with a broken pin connector on your mobile phone? Don’t worry, you’re not alone. The pin connector, located on the charging port of your device, is a crucial component that allows for seamless charging and data transfer. However, it can become damaged or broken due to constant use or mishandling.

In this article, we will explore some effective methods to fix a broken pin connector on your mobile phone. Whether you’re dealing with a bent pin, a loose connection, or a completely broken pin, we’ve got you covered. So, grab your toolkit, roll up your sleeves, and let’s dive into the world of DIY mobile phone repairs.

Inside This Article

- Symptoms of a Broken Pin Connector

- Tools and Materials Needed

- Step 1: Assess the Damage

- Step 2: Gather Necessary Supplies

- Step 3: Remove Broken Pin Connector

- Step 4: Clean the Area

- Step 5: Prepare the Replacement Pin Connector

- Step 6: Attach the New Pin Connector

- Step 7: Test the Connection

- Conclusion

- FAQs

Symptoms of a Broken Pin Connector

A broken pin connector in your mobile device can cause a range of issues, impacting its functionality and performance. Being aware of the symptoms of a broken pin connector is crucial in identifying and resolving the problem. Here are some common signs that indicate a broken pin connector:

- Intermittent Charging: One of the most noticeable symptoms is intermittent charging. You may find that your device charges only if you hold the charging cable at a certain angle or apply pressure. This can be a clear indication that the pin connector is no longer making a secure connection.

- Loose or Wobbly Connection: Another telltale sign of a broken pin connector is a loose or wobbly connection. When you plug in your device, it may not fit snugly or may have some play, indicating that the pin connector is damaged.

- Inconsistent Data Transfer: If you experience issues with data transfer between your device and a computer or other devices, it could be due to a broken pin connector. You may observe slow transfer speeds, frequent disconnections, or complete failure to establish a connection.

- Unresponsive Accessories: A broken pin connector can also cause accessories such as headphones or speakers to become unresponsive. If you plug in your headphones and there is no sound or if your device doesn’t recognize the accessory, it could be a sign of a broken pin connector.

- Visible Damage: In some cases, you may be able to visually identify a broken pin connector. Look for any bent, missing, or damaged pins in the charging port. Physical damage is a clear indication that the pin connector needs repair or replacement.

If you encounter any of these symptoms, it’s essential to address the issue promptly. Ignoring a broken pin connector can lead to further damage to your device and may render it unusable. Fortunately, there are steps you can take to fix a broken pin connector, which will be discussed in the subsequent sections.

Tools and Materials Needed

When it comes to fixing a broken pin connector, having the right tools and materials on hand is essential. Here is a list of what you will need before you embark on this repair:

- Screwdriver set: A precision screwdriver set with various tip sizes will be necessary for opening up the device and accessing the broken connector.

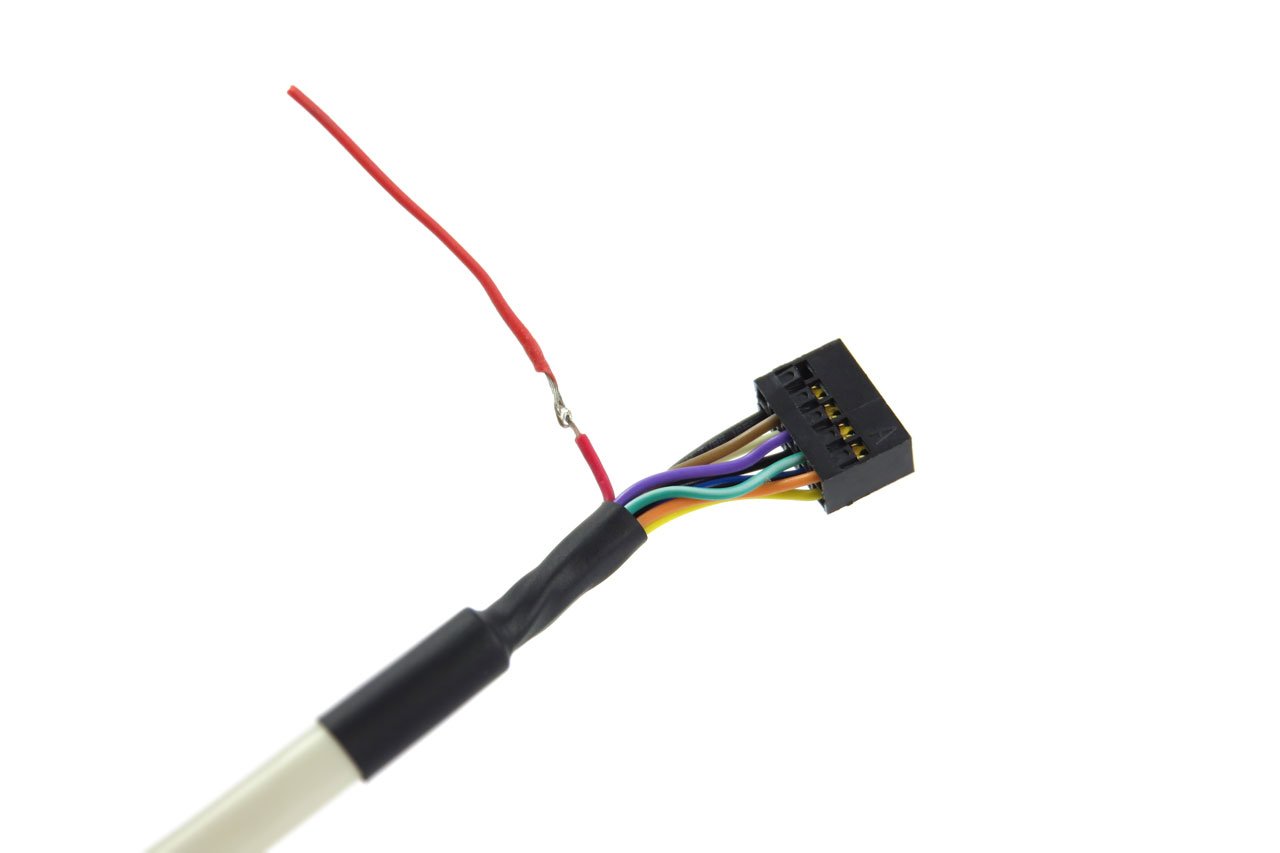

- Replacement pin connector: You will need to obtain a new pin connector that matches the specifications of the broken one. This can usually be found at electronics stores or obtained online.

- Soldering iron: In order to securely connect the new pin connector, a soldering iron is required. Make sure to choose a soldering iron with a fine tip for precise soldering.

- Solder wire: High-quality solder wire with flux is essential for creating a strong and stable connection between the pin connector and the device.

- Desoldering pump or wick: If the broken connector needs to be removed from the device, a desoldering pump or wick will be necessary to safely and effectively remove the old solder.

- Heat shrink tubing: This tubing is used to insulate and protect the soldered connections, ensuring durability and preventing short circuits.

- Wire cutters/strippers: These tools are needed to trim excess wire length and strip insulation from the wires if necessary during the repair process.

- Cleaning solution: A cleaning solution, such as isopropyl alcohol, is beneficial for removing dirt, debris, or corrosion from the area surrounding the broken pin connector.

- Tweezers: Tweezers can be helpful for holding small components or wires in place while soldering or making delicate adjustments.

- Magnifying glass: A magnifying glass or a magnifying desk lamp is highly recommended, especially if you are working with tiny connectors or limited visibility.

- Anti-static mat/bracelet: To protect the delicate electronic components of the device from static discharge, an anti-static mat or bracelet should be used during the repair process.

Make sure you have all these tools and materials ready before you begin the pin connector repair. Having everything you need at hand will streamline the process and ensure a successful repair.

Step 1: Assess the Damage

Before you can begin fixing a broken pin connector, it is essential to assess the extent of the damage. This step is crucial as it helps you determine the appropriate course of action and the level of repair required.

Start by carefully examining the pin connector. Look for any visible signs of damage, such as bent or broken pins, loose connections, or signs of corrosion. Use a magnifying glass if necessary to get a closer look.

If you are unsure whether the pin connector is the issue or if there are other underlying problems, such as a damaged circuit board or faulty wiring, it is recommended to consult a professional or seek technical support.

Additionally, check for any accompanying symptoms that may indicate a broken pin connector. These can include intermittent or no connection, difficulty charging or syncing the device, or error messages displayed on the screen.

By thoroughly assessing the damage, you will be able to proceed with confidence and ensure that you are targeting the specific issue correctly. This will ultimately save you time and effort in the repair process.

Step 2: Gather Necessary Supplies

Before you start repairing a broken pin connector, it’s important to gather all the necessary supplies. Having the right tools and materials at hand will not only make the repair process smoother but also ensure the best possible outcome. Here are the essential items you will need:

- Replacement Pin Connector: Make sure to choose a pin connector that matches the specifications of the one you’re replacing. You can find suitable replacements at electronics stores or online.

- Soldering Iron: A soldering iron is a vital tool for any pin connector repair. It allows you to attach the replacement connector securely to the circuit board.

- Soldering Wire: High-quality soldering wire is required to create a strong and reliable connection between the pin connector and the circuit board.

- Desoldering Pump or Wick: If the broken pin connector is still attached to the circuit board, you will need a desoldering pump or wick to safely remove the solder and disconnect the old connector.

- Flux Pen: Flux helps in the soldering process by improving the flow of solder and enhancing the adhesion between the pin connector and the circuit board.

- Tweezers: Tweezers enable precise handling of the pin connector and other small components during the repair.

- Wire Cutters: Wire cutters are necessary for trimming excess wire and ensuring a neat and tidy repair job.

- Safety Glasses: It’s always wise to wear safety glasses to protect your eyes from any solder or debris that may come loose during the repair.

By gathering these supplies before beginning the repair process, you can proceed with confidence and increase the chances of successfully fixing the broken pin connector. Always remember to follow proper safety precautions and work in a well-ventilated area when using a soldering iron.

Step 3: Remove Broken Pin Connector

When dealing with a broken pin connector, the next step is to remove the damaged component from your device. Follow these steps to safely remove the broken pin connector:

1. Start by gathering the necessary tools for this task. You will need a small screwdriver set, tweezers, and a magnifying glass or lighted magnifier. These tools will help you accurately and carefully detach the broken pin connector.

2. Before you begin, make sure to power off your device. This will prevent any accidental damage or electrical shocks while working on the pin connector. Safety should always be a top priority.

3. Carefully inspect the broken pin connector and its surrounding area. Identify the pins or wires that are damaged or disconnected. This will help you determine the best angle and approach to remove the connector without causing further harm.

4. Using the small screwdriver or tweezers, gently pry apart and release any clips or fasteners that hold the pin connector in place. Be cautious and apply gentle pressure to avoid unnecessary force or damage to the device.

5. If the pin connector is soldered onto the board, you may need to use a soldering iron and desoldering pump to remove it. Take your time and ensure that you follow proper safety precautions while handling the soldering iron.

6. Once all clips and fasteners are released or the solder joints are desoldered, carefully lift the broken pin connector away from the device. Pay close attention to prevent any damage to the surrounding components or circuitry.

7. After successfully removing the broken pin connector, inspect the area for any debris or residue. Clean the area with a lint-free cloth or alcohol swab to ensure that the new pin connector will have a secure and clean connection.

By following these steps, you can effectively remove a broken pin connector from your device. Take your time and exercise caution throughout the process to avoid causing further damage.

Step 4: Clean the Area

Now that you have removed the broken pin connector, it’s essential to clean the area before attaching the replacement. Cleaning the area ensures that there’s no debris or residue that could interfere with the new connection.

Here’s how you can clean the area effectively:

- Use a soft brush or cotton swab to gently remove any dirt, dust, or other particles from the pin holes and surrounding area.

- If there’s any visible corrosion on the contacts, you can use a small amount of isopropyl alcohol and a clean cloth to carefully clean the affected areas. Remember to be gentle and avoid using excessive force as you clean to avoid causing any further damage.

- For stubborn residue or corrosion, you may need to use a small amount of contact cleaner. Apply it to a cotton swab or cloth and gently rub the affected areas until the residue is removed. Make sure to follow the instructions provided with the contact cleaner and avoid getting it on any other components of the device.

- Once the area is clean, use a clean, dry cloth or compressed air to remove any moisture. Ensure that the area is completely dry before proceeding to the next step.

Cleaning the area thoroughly helps create a clean and secure connection for the new pin connector. It also prevents any potential issues that may arise from debris or corrosion, ensuring the longevity and reliability of the repaired connection.

Step 5: Prepare the Replacement Pin Connector

Now that you have removed the broken pin connector, it’s time to prepare the replacement pin connector. This step is crucial to ensure a seamless and secure connection for your device. Follow these steps to properly prepare the replacement pin connector:

- Choose the right replacement: Make sure you have the correct replacement pin connector that matches the specifications of your device. Check for compatibility in terms of size, shape, and pin configuration. You can find replacement connectors online or at electronics stores.

- Inspect the replacement: Before proceeding, carefully examine the replacement pin connector for any defects or damage. Look for any bent pins, cracks, or abnormalities. It’s essential to work with a fully functional replacement connector.

- Clean the replacement: Sometimes, replacement connectors may accumulate dust or debris during storage or shipping. Use a gentle cleaning solution, such as isopropyl alcohol, and a soft cloth to clean the pin connector. Ensure that it is free from any residue or contaminants that may hinder the connection.

- Align the pins: Take a close look at the pins on both the replacement connector and the device’s socket. Ensure that the pins are properly aligned and within the correct orientation. Misaligned pins can result in poor connection or damage to the device.

- Apply a conductive adhesive: Depending on the type of replacement pin connector you have, you may need to use a conductive adhesive to secure it in place. Follow the manufacturer’s instructions for applying the adhesive carefully. Be sure to apply just the right amount to ensure a reliable bond without excess adhesive causing interference.

- Double-check the fit: Once the adhesive is applied, carefully insert the replacement pin connector into the device’s socket. Ensure that it fits snugly and securely without any wobbling or loose pins. This step is crucial to ensure a proper and stable connection.

By following these steps, you can effectively prepare the replacement pin connector for installation. Taking the time to properly prepare the replacement connector ensures a smooth and reliable connection, contributing to the overall functionality and performance of your device.

Step 6: Attach the New Pin Connector

Once you have prepared the replacement pin connector, it’s time to attach it to your device. Follow these steps to ensure a secure and reliable connection:

- Identify the correct orientation: Carefully examine the replacement pin connector and make sure you understand its correct orientation. The pins should align with the corresponding slots or receptacles on your device.

- Align the pin connector: Gently position the replacement pin connector over the broken pin connector’s location. Ensure that the pins are aligned with the corresponding holes or contacts.

- Apply pressure: Using your fingers or a small tool, apply slight pressure to secure the connection. Be careful not to use excessive force as it might damage the pins or the surrounding components.

- Test the connection: Once the new pin connector is securely attached, it’s essential to test the connection. Plug in your device and check if it responds appropriately. Wiggle the connector gently to ensure there is no loose connection or intermittent functionality.

- Secure the pin connector: If the connection passes the testing phase, you should secure the pin connector in place. Depending on the device and connector type, you may need to use adhesive, clips, or screws to keep it firmly attached. Follow the manufacturer’s guidelines or consult a professional if you’re unsure about the best method to secure the connector.

Remember, the proper attachment of the new pin connector is crucial for the reliable functionality of your device. Take your time and ensure that the pins are correctly aligned and securely fastened. If you’re uncertain about any step, it’s always recommended to seek assistance from a professional technician.

Step 7: Test the Connection

After successfully attaching the new pin connector, the final step is to test the connection to ensure that it is working properly. This is an important step to verify that your efforts in fixing the broken pin connector have been successful.

To test the connection, follow these steps:

- Power on the device: Turn on the device that you have fixed the pin connector for. Whether it is a mobile phone, tablet, or other electronic device, make sure that it is properly powered on.

- Check for a stable connection: Connect the device to a charger or computer using the charging cable or data cable, depending on the purpose of the pin connector. Ensure that the connection is stable and secure.

- Observe for charging or data transfer: If the purpose of the pin connector is charging, monitor the device to ensure that it is receiving power and charging as expected. If the purpose is data transfer, check if the device is recognized by the computer and able to transfer data smoothly.

- Test functionality: Depending on the device, test other functionalities that rely on the pin connector, such as audio output, headphone connectivity, or any other relevant features. Verify that everything is functioning correctly.

- Repeat the test: It is recommended to repeat the test with different charging cables or data cables to ensure that the connection is consistent and reliable.

If you encounter any issues during the testing process, double-check the installation of the new pin connector and make sure that it is properly connected. If the problem persists, you may need to seek professional assistance or consider replacing the pin connector again.

By thoroughly testing the connection, you can have peace of mind knowing that your device is functioning properly and the broken pin connector has been successfully fixed.

Conclusion

Fixing a broken pin connector on a mobile phone can be a challenging task, but with the right tools and techniques, it is possible to restore functionality to your device. Whether it is a damaged charging port, a broken headphone jack, or a faulty SIM card slot, there are various options available to fix the issue.

Remember to exercise caution and patience when attempting any repairs, and if you are unsure, it is best to seek professional assistance. Additionally, always ensure you have the proper tools and follow step-by-step instructions to avoid further damage.

By fixing a broken pin connector, you can save yourself from the hassle and expense of purchasing a new phone, and extend the lifespan of your device. So, don’t let a broken pin connector limit your smartphone’s potential – take the necessary steps to get it back up and running!

FAQs

Q: What is a pin connector?

A: A pin connector is a small component found in electronic devices, such as cell phones, that is responsible for establishing a connection between two parts of the device. It typically consists of a series of metal pins that fit into corresponding slots or sockets to create a secure and functional connection.

Q: How can a pin connector break?

A: Pin connectors can break due to various reasons, such as physical damage, excessive force, or wear and tear over time. Accidents like dropping a device or mishandling it can cause the pins to bend, snap, or become misaligned, resulting in a broken pin connector.

Q: What are the signs of a broken pin connector?

A: The signs of a broken pin connector may include intermittent or no connection between the device’s components, difficulty in charging or syncing the device, or error messages related to the device’s connectivity. Additionally, visible damage to the pins or sockets can indicate a broken pin connector.

Q: Can a broken pin connector be repaired?

A: In some cases, a broken pin connector can be repaired. However, the feasibility of repair depends on the extent of the damage and the availability of replacement parts. It is recommended to consult a professional technician or service center to evaluate the possibility of repair for your specific device.

Q: How can I prevent a pin connector from breaking?

A: To prevent a pin connector from breaking, it is important to handle electronic devices with care and avoid applying unnecessary force. Be gentle when plugging and unplugging cables or accessories and avoid dropping the device. Using protective cases or covers can also provide an extra layer of protection for the pin connector.