If you’re experiencing issues with your ribbon cable connector, you’ve come to the right place. A faulty ribbon cable connector can cause a variety of problems, from disconnection to poor signal quality. However, before you panic, it’s essential to know that fixing a ribbon cable connector is possible, and you don’t always have to replace the entire device. In this article, we will guide you through the steps to fix a ribbon cable connector effectively. Whether you are a tech enthusiast or a smartphone owner, this article will provide you with the knowledge and tools you need to solve this common issue. So let’s dive in and learn how to repair a ribbon cable connector like a pro!

Inside This Article

- What is a Ribbon Cable Connector?

- Common Issues with Ribbon Cable Connectors

- Tools and Materials Needed

- Step-by-Step Guide to Fixing a Ribbon Cable Connector

- Additional Tips and Precautions

- Conclusion

- FAQs

What is a Ribbon Cable Connector?

A ribbon cable connector, also known as a flat cable connector or a flat flex connector (FFC), is a type of electrical connector used to connect a flat, flexible cable to a device or another component. It is designed to provide a reliable and secure connection for transmitting electrical signals between different parts of an electronic device.

Ribbon cable connectors are typically made up of a flat, rectangular-shaped housing with a series of closely spaced metal contacts or pins. These pins align with the corresponding conductors on the ribbon cable, allowing for the transmission of electrical signals. The connector is then secured in place using various mechanisms, such as latches, clips, or screws, to ensure a stable and dependable connection.

Overall, the primary function of a ribbon cable connector is to establish a communication link between different components of an electronic device, enabling the transmission of data, power, or both.

Common uses for ribbon cable connectors:

Ribbon cable connectors are widely used in various industries and applications due to their flexibility and versatility. Here are some common uses for ribbon cable connectors:

- Computers and Data Storage: Ribbon cable connectors are commonly found in computers and data storage devices, such as hard drives, optical drives, and solid-state drives (SSDs). They enable the transfer of data between the motherboard and these storage devices.

- Printers and Scanners: Ribbon cable connectors are essential in printers and scanners, allowing for the connection between the control board and various components, such as print heads, motors, and sensors.

- Flat Panel Displays: Ribbon cable connectors are used in flat panel displays, such as LCD and OLED screens, to connect the display panel to the controller board, enabling the transmission of video signals.

- Automotive Electronics: Ribbon cable connectors find applications in automotive electronics for connecting various components, including dashboard displays, control modules, sensors, and wiring harnesses.

- Consumer Electronics: Ribbon cable connectors are found in a wide range of consumer electronics, including smartphones, tablets, digital cameras, and gaming consoles. They facilitate the internal connectivity between different modules and components.

These are just a few examples of the many applications where ribbon cable connectors play a crucial role in establishing reliable connections within electronic devices and systems.

Common Issues with Ribbon Cable Connectors

When dealing with ribbon cable connectors, there are several common issues that can arise. Understanding these problems and how to address them can help you troubleshoot and fix any connectivity issues you may encounter. The three main issues with ribbon cable connectors are:

1. Loose or Improper Connection: One of the most common issues with ribbon cable connectors is when the connection becomes loose or improperly attached. This can result in a weak or unstable connection, leading to intermittent or no signal transmission at all. It is important to ensure that the ribbon cable connector is securely fastened to its corresponding socket, and any locking mechanisms are engaged if available.

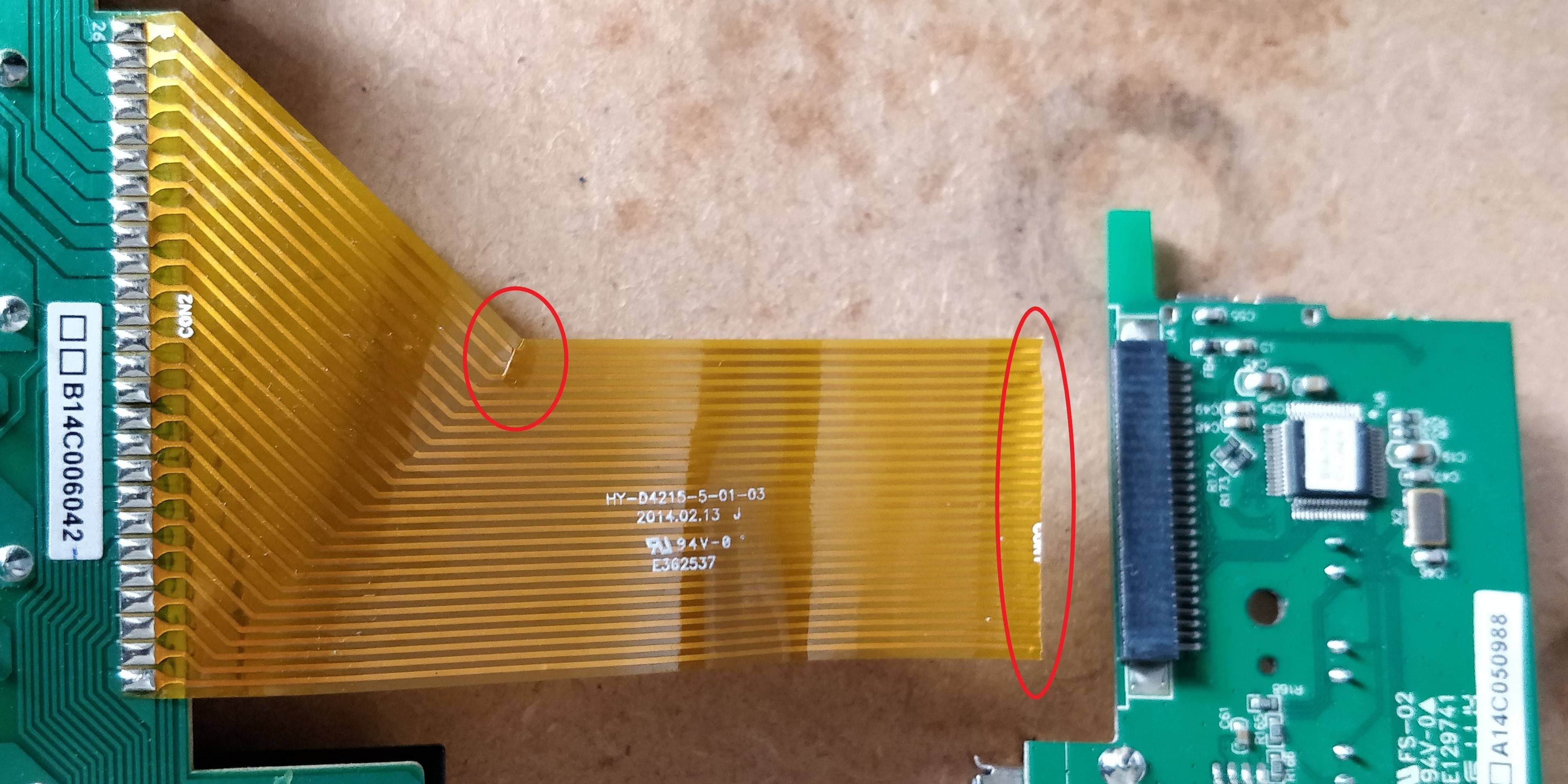

2. Bent or Damaged Pins: Another issue that can occur with ribbon cable connectors is bent or damaged pins. These pins are responsible for transmitting the electrical signals between the ribbon cable and the device. If any of the pins become bent, broken, or damaged in any way, it can result in a poor or non-existent connection. Carefully inspect the pins for any deformities and gently straighten them if possible. If a pin is completely broken or damaged beyond repair, the connector may need to be replaced.

3. Misalignment of the Connector: The misalignment of the connector can also cause connectivity issues. Sometimes, when reconnecting a ribbon cable, it may not be properly aligned with the socket, resulting in a poor connection. Ensure that the connector is firmly and correctly aligned with the socket before securing it in place. This will help guarantee a proper and stable connection.

Tools and Materials Needed

When it comes to fixing a ribbon cable connector, having the right tools and materials on hand is essential. Here are the items you’ll need to successfully tackle the task:

Screwdriver: A screwdriver with the appropriate size and type of head is necessary for opening the device and accessing the ribbon cable connector.

Pliers: Pliers can be handy for gripping and manipulating small components, such as the ribbon cable itself or any bent pins you may encounter.

Cleaning solution: A cleaning solution specifically designed for electronics can help remove dirt, dust, and grime that may be affecting the connection.

Isopropyl alcohol: Isopropyl alcohol is a popular choice for cleaning electronics due to its ability to dissolve oils and remove contaminants without leaving residue behind.

Cotton swabs: Cotton swabs are ideal for applying the cleaning solution and reaching small, intricate parts of the connector where dirt and debris tend to accumulate.

Electrical tape: Electrical tape can be used to secure the ribbon cable and ensure a stable connection. It provides insulation and protection against any accidental contact with other components.

Having these tools and materials readily available will make the process of fixing a ribbon cable connector much smoother and more efficient. Now that you’re equipped, let’s move on to the step-by-step guide.

Step-by-Step Guide to Fixing a Ribbon Cable Connector

Step 1: Power off and unplug the device

Before starting any repairs, it is crucial to ensure your safety. Power off the device that contains the ribbon cable connector and unplug it from the power source. This step will prevent any electrical shocks and damage to the device or yourself.

Step 2: Assess the connector for any visible issues

Take a close look at the ribbon cable connector for any visible signs of damage or misalignment. Check for loose or disconnected connectors, bent or damaged pins, or any debris that might be blocking the connection. Identifying the problem will help you determine the appropriate steps for fixing it.

Step 3: Realign the connector and secure it properly

If you notice that the ribbon cable connector is loose or not properly aligned, gently push it back into place. Make sure it is properly seated in its socket, aligning with the corresponding pins or contacts. Use gentle pressure to secure the connector, being careful not to apply excessive force that could cause further damage.

Step 4: Inspect and fix any bent or damaged pins

If you notice any bent, broken, or damaged pins on the ribbon cable connector, you will need to gently realign or fix them. Using a pair of pliers or tweezers, carefully straighten any bent pins, ensuring they are properly aligned with the other pins. If a pin is broken or damaged beyond repair, you may need to replace the connector entirely.

Step 5: Clean the connector and contacts with isopropyl alcohol and cotton swabs

To ensure a reliable connection, it is important to clean the ribbon cable connector and the corresponding contacts. Use a small amount of isopropyl alcohol and a cotton swab to gently clean both the connector and the contacts. This will remove any dirt, debris, or oxidation that may interfere with the connection.

Step 6: Reconnect the ribbon cable securely

Once the connector and contacts are clean, carefully reconnect the ribbon cable to the connector. Ensure it is properly aligned and fully inserted into the socket. Take care not to force the cable into place, as this can cause damage to both the cable and the connector. Double-check that the connection is secure and snug.

Step 7: Test the connection and ensure it is working properly

After completing the previous steps, power on the device and test the ribbon cable connection. Ensure that the connection is stable and that the device functions as expected. If you continue to experience issues, double-check the steps you have followed or consider seeking professional assistance.

Additional Tips and Precautions

When it comes to fixing a ribbon cable connector, it’s not just about the repair process itself. Proper handling and care of the connector are essential for maintaining its longevity and functionality. Here are some additional tips and precautions to keep in mind:

-

Proper handling and care of ribbon cable connectors:

Handle the connectors with care, avoiding any excessive force or rough handling. The delicate pins and contacts can easily be damaged if mishandled. When disconnecting the ribbon cable, make sure to do it gently and evenly without pulling or twisting it forcefully.

Always grasp the connector itself, and not the cable, when disconnecting or reconnecting it. This will help prevent any unnecessary strain on the cable and reduce the risk of damaging the connector.

-

Avoiding excessive force when manipulating the connector:

When aligning or securing the ribbon cable connector, it’s important to be gentle and avoid applying excessive force. Pressing too hard or using too much pressure can cause the pins to bend or break, leading to connectivity issues.

Take your time and make small adjustments as needed. If you encounter resistance, stop and reassess the alignment before proceeding. Remember, it’s better to be patient and cautious than to risk damaging the connector.

-

Regular maintenance to prevent future issues:

Performing regular maintenance on your ribbon cable connectors can help prevent future problems and extend their lifespan. This includes periodically inspecting the connectors for any signs of damage or wear.

Take the time to clean the connectors and contacts using isopropyl alcohol and cotton swabs. This will remove any dirt, dust, or debris that may have accumulated, ensuring optimal connectivity.

Additionally, consider securing the connection with electrical tape or another suitable method to prevent any accidental disconnection due to movement or vibration.

By following these additional tips and precautions, you can ensure the proper handling, long-term functionality, and reliability of your ribbon cable connectors. Taking care of these small but important details will go a long way in preventing issues and maintaining the optimal performance of your devices.

Conclusion

In conclusion, fixing a ribbon cable connector is a common issue that many people face, but it is not an impossible task. By following the steps outlined in this guide, you can troubleshoot and repair your ribbon cable connector efficiently.

Remember to approach the process with caution, patience, and the right tools. Take your time to inspect the connector, clean it if necessary, and ensure that it is properly aligned during reassembly. If you encounter any difficulties or are unsure about any step, it is always best to consult a professional or seek assistance from the manufacturer.

With the right knowledge and methodical approach, you can successfully fix a ribbon cable connector, saving yourself the hassle and expense of replacing the entire component. So, don’t be afraid to roll up your sleeves and give it a try!

FAQs

1. What is a ribbon cable connector?

A ribbon cable connector is a type of electrical connector used to connect flat ribbon cables, which consist of multiple wires arranged in a parallel fashion. It serves as a crucial component in various electronic devices, providing a reliable connection between different components or peripherals.

2. What are the common issues with ribbon cable connectors?

Some common issues with ribbon cable connectors include loose connections, bent pins, damaged cables, and improper alignment. These issues can result in disrupted signals, intermittent connectivity, or complete failure of the connected devices.

3. How can I fix a loose ribbon cable connector?

To fix a loose ribbon cable connector, gently unplug the connector and inspect the pins and socket for any dirt or debris that may be causing the looseness. Clean the pins and socket if necessary. Then, reinsert the connector firmly into the socket, ensuring that it is properly aligned and seated securely.

4. My ribbon cable connector has bent pins, what should I do?

If you notice bent pins in your ribbon cable connector, you should not try to straighten them using force, as it may cause further damage. Instead, use a fine-point tweezer or a similar tool to carefully straighten each pin individually. Take caution to avoid applying excessive pressure, as the pins are delicate and can break easily.

5. Can I repair a damaged ribbon cable connector?

In some cases, it may be possible to repair a damaged ribbon cable connector. However, this depends on the extent of the damage. If the damage is limited to the cable itself, it may be feasible to replace the damaged portion by carefully reattaching the wires and insulating them properly. If the damage is severe or involves the connector itself, it is often more practical to replace the entire connector.