Imagine the world without smartphones, tablets, or laptops. It’s hard to picture, right? In today’s digital age, these devices have become an essential part of our lives. But have you ever wondered what makes them work so seamlessly? One crucial component that often goes unnoticed is the PCB connector.

A PCB connector, also known as a Printed Circuit Board connector, is a crucial electronic device that joins different electronic components to a printed circuit board. It acts as a bridge, enabling the transfer of signals and power between various parts of the circuit. The PCB connector plays a vital role in ensuring a stable and reliable connection, allowing the smooth functioning of the device.

Inside This Article

- PCB Connector Basics – Definition of a PCB connector- Purpose and function of a PCB connector – Types of PCB connectors – Importance of choosing the right PCB connector

- Key Components of a PCB Connector

- Factors to Consider When Choosing a PCB Connector

- Conclusion

- FAQs

PCB Connector Basics – Definition of a PCB connector- Purpose and function of a PCB connector – Types of PCB connectors – Importance of choosing the right PCB connector

PCB connectors, also known as printed circuit board connectors, are electronic components that provide a means of connecting various electrical circuits on a PCB. They are crucial for establishing reliable connections and enabling the transfer of signals or power between different components of an electronic device or system.

The main purpose of a PCB connector is to provide a secure and stable connection between the PCB and external devices or components. They enable easy assembly and disassembly, allowing for efficient maintenance and repair of electronic devices. Additionally, PCB connectors play a vital role in minimizing signal loss, preventing short circuits, and ensuring overall system integrity.

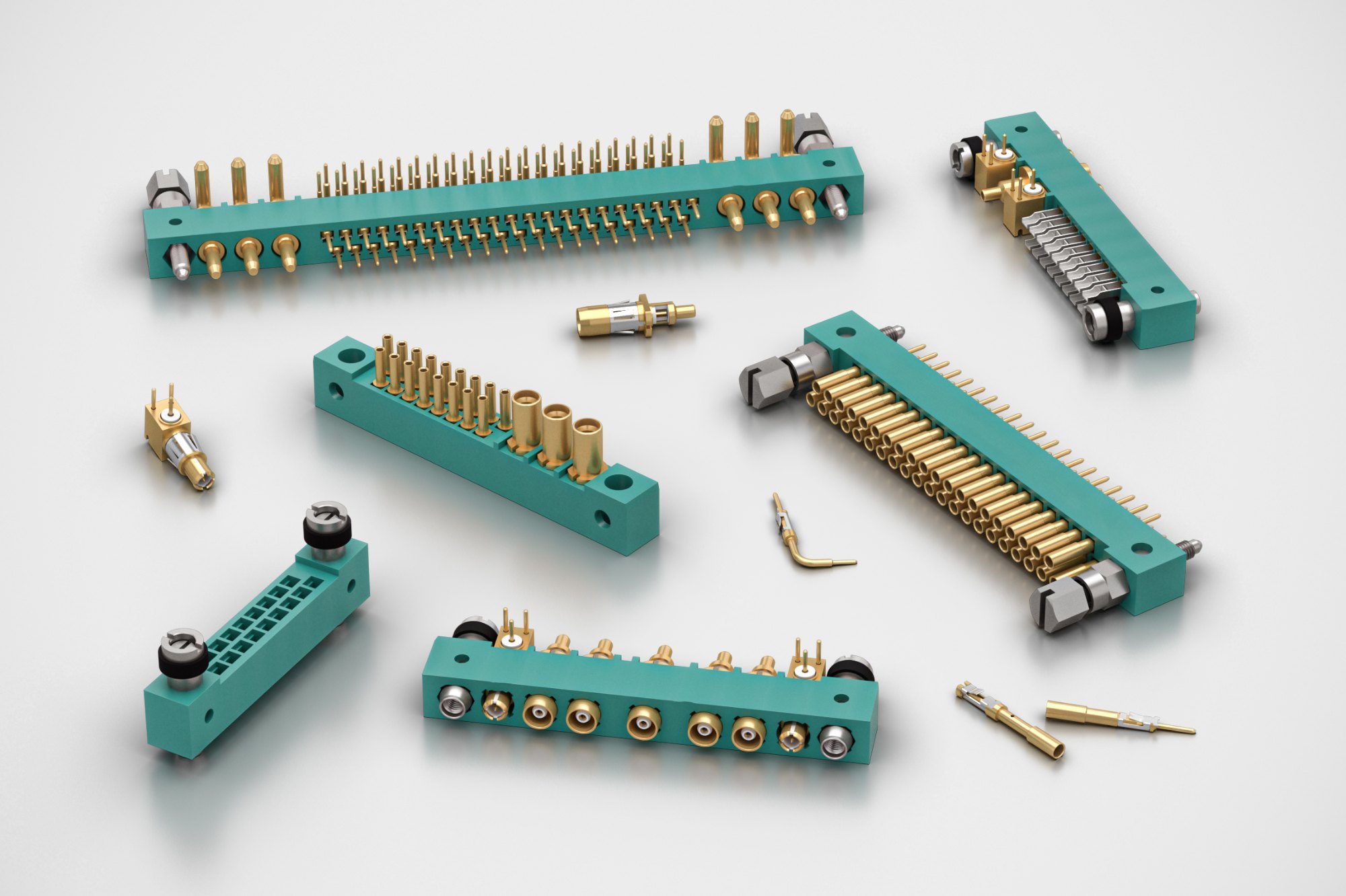

There are various types of PCB connectors available, each designed to serve specific functions and requirements. Some common types include:

- Pin connectors: These connectors consist of a series of pins that fit into corresponding sockets to establish electrical connections. They are commonly used for power supply connections and data transfer.

- Socket connectors: These connectors feature receptacles that receive pins or leads from other components. They are widely used in applications where frequent plugging and unplugging is required, such as in computer peripherals.

- Edge connectors: These connectors are designed to be inserted into slots or edges of the PCB. They provide a reliable connection for components such as memory modules.

- Wire-to-board connectors: These connectors are used to establish connections between wire cables and the PCB. They are commonly found in applications such as power supply connections and panel-mounted devices.

- Board-to-board connectors: These connectors enable the connection between two separate PCBs. They are essential for complex circuit designs and multi-board systems.

Choosing the right PCB connector is crucial for the proper functioning and longevity of an electronic device. Factors to consider include:

- Electrical specifications: The connector should meet the voltage, current, and signal requirements of the application.

- Mechanical considerations: The connector should have the appropriate size, shape, and mounting style to fit the device and the PCB layout.

- Environmental conditions: The connector should be able to withstand the temperature, humidity, and other environmental factors it will be exposed to.

- Size and footprint requirements: The connector should fit within the available space on the PCB and match the desired footprint.

- Cost and availability: The connector should be cost-effective and readily available to ensure efficient production and maintenance.

Key Components of a PCB Connector

A PCB connector is composed of several key components that work together to ensure a reliable and secure electrical connection. Understanding these components is essential for selecting the right connector for your specific application. Here are the key components of a PCB connector:

1. Pin/Socket Contacts: The pin and socket contacts are the core elements of a PCB connector. The pin is typically a male connector, while the socket is the female counterpart. These contacts establish the electrical connection between the PCB and the mating connector. They are designed to provide a secure and low-resistance connection, ensuring proper transmission of electrical signals.

2. Housing or Connector Body: The housing or connector body encloses the pin/socket contacts and provides mechanical support and protection. It is usually made of durable plastic or metal materials. The design of the housing may vary depending on the connector type and application. It includes features such as alignment guides and keying mechanisms to ensure proper mating and prevent misconnection.

3. Locking Mechanisms: Locking mechanisms are used to secure the connection between the PCB connector and the mating connector. They prevent unintended disconnection due to vibrations, shock, or accidental pulling of cables. Common types of locking mechanisms include latch locks, screw locks, snap locks, and push-pull locks. The choice of locking mechanism depends on the application requirements and level of security needed.

4. Insulation Materials: Insulation materials are used to separate the pins and sockets within the connector body, preventing electrical short circuits. They are typically made of dielectric materials with high insulation properties such as plastic or rubber. The choice of insulation material depends on factors such as operating voltage, temperature, and environmental conditions.

5. Plating and Coating Options: Plating and coating options are applied to the contact surfaces of the pin and socket to enhance conductivity and prevent corrosion. Common plating options include gold, tin, silver, and nickel. Coatings such as thin layers of silicone or epoxy can be used to protect the connector from moisture, dust, and other contaminants.

By understanding the key components of a PCB connector and their role in ensuring a reliable connection, you can make informed decisions when selecting a connector for your PCB design. Consider factors such as electrical specifications, mechanical requirements, environmental conditions, and cost to choose the right connector that meets your application needs.

Factors to Consider When Choosing a PCB Connector

When selecting a PCB connector for your electronic design, it is crucial to consider several factors to ensure optimal performance and compatibility. Each of these factors plays a vital role in determining the suitability of a connector for your specific application. Here are the key factors to keep in mind:

1. Electrical Specifications

The electrical specifications of a PCB connector are crucial in determining its compatibility with the intended application. It is essential to consider parameters such as voltage rating, current carrying capacity, contact resistance, and signal integrity. These specifications should align with the requirements of your circuit design to ensure reliable and efficient performance.

2. Mechanical Considerations

Another critical aspect to consider is the mechanical compatibility of the PCB connector. Factors such as the mating mechanism, mating cycle durability, retention force, and ease of installation should be evaluated. Additionally, the mechanical dimensions, including the size, shape, and mounting method, must align with the available space and mechanical constraints of your PCB design.

3. Environmental Conditions

Environmental conditions can significantly impact the performance and lifespan of a PCB connector. Considerations such as temperature range, humidity, vibration, shock resistance, and exposure to chemicals or other potentially corrosive substances should be taken into account. Choosing a connector that meets the environmental requirements of your application will ensure long-term reliability and durability.

4. Size and Footprint Requirements

The size and footprint of the PCB connector are crucial, especially when space is limited in your electronic design. You must consider the overall dimensions, pin spacing, and arrangement of the connector to fit your PCB layout effectively. Additionally, it is important to verify that the connector’s footprint aligns with industry-standard footprints or any specific requirements of your PCB manufacturing process.

5. Cost and Availability

Cost and availability are practical considerations when choosing a PCB connector for your project. Evaluate the cost-effectiveness of the connector while ensuring that it meets your performance requirements. Additionally, consider the availability and lead times of the connector, especially for long-term production or maintenance purposes.

By considering these key factors – electrical specifications, mechanical considerations, environmental conditions, size and footprint requirements, as well as cost and availability – you can make an informed decision when selecting a PCB connector. Taking the time to evaluate these factors will help ensure optimal performance, compatibility, and reliability for your electronic design.

Conclusion

In conclusion, PCB connectors play a crucial role in the world of electronics and technology. These small yet mighty components are responsible for creating secure and reliable connections between different electronic circuits, ensuring smooth communication and functionality. From smartphones to computers, automotive systems to home appliances, PCB connectors are essential in enabling the seamless operation of various devices.

With the rapid advancements in technology and the increasing demand for smaller, more efficient devices, the importance of PCB connectors cannot be understated. As new technologies emerge, the need for high-speed data transfer, compact designs, and reliable power transmission will continue to drive innovation in the field of PCB connectors.

Whether you’re a tech enthusiast or a professional in the electronics industry, understanding PCB connectors is essential to making informed choices when it comes to mobile accessories and other technological devices. So next time you plug in your headphones, charge your phone, or connect an external device, remember the invisible heroes that make it all possible – the PCB connectors.

FAQs

1. What is a PCB connector?

A PCB connector, also known as a printed circuit board connector, is an electronic component that allows for the connection and disconnection of electrical circuits on a printed circuit board (PCB). It is designed to provide a reliable connection between different components, modules, or devices on a PCB, enabling the transfer of electrical signals and power.

2. Why are PCB connectors important?

PCB connectors play a crucial role in the functioning of electronic devices as they facilitate the interconnection of various components on a PCB. They provide a secure and reliable connection, ensuring the smooth transmission of signals and power between different parts of an electronic system. Without PCB connectors, it would be challenging to assemble and maintain complex electronic circuits, limiting the functionality and versatility of electronic devices.

3. What are the different types of PCB connectors?

There are various types of PCB connectors available, each designed for specific applications and requirements. Some common types of PCB connectors include:

– Header connectors: These connectors have pins that fit into corresponding sockets or receptacles. They are widely used for making connections between PCBs or between PCBs and external devices.

– Terminal blocks: These connectors feature screw terminals that allow for easy and secure wire-to-board connections. They are commonly used in industrial applications and power distribution systems.

– Board-to-board connectors: As the name suggests, these connectors facilitate connections between two PCBs. They enable the transmission of signals and power between different circuit boards within an electronic system.

– Wire-to-board connectors: These connectors are used to connect wires to a PCB, providing a reliable electrical connection. They are commonly found in applications where removable connections are required, such as in consumer electronics.

4. How do I choose the right PCB connector for my application?

When selecting a PCB connector, several factors need to be considered. These include:

– Electrical specifications: Ensure that the connector can handle the required voltage, current, and signal characteristics of your application.

– Mechanical compatibility: Check the dimensions, mounting options, and mating interfaces of the connector to ensure it can be properly integrated with your PCB and other components.

– Environmental considerations: Determine the operating conditions, such as temperature, moisture, and vibration, and choose a connector that can withstand these conditions.

– Reliability and durability: Look for connectors that are known for their high-quality construction and long-term reliability to ensure a stable and consistent connection.

– Cost-effectiveness: Consider your budget and the overall cost of the connector, including any additional accessories or tools required for installation.

5. Can I replace a PCB connector myself?

Replacing a PCB connector can be a complex task and may require advanced soldering skills and specialized tools. It is recommended to consult a professional or an experienced technician who is familiar with PCB assembly and repair. They can assess the situation, determine the appropriate replacement connector, and ensure it is installed correctly to maintain the integrity of the circuit.