In today’s world, where everything is connected and relies heavily on electronic devices, having a properly functioning connector is essential. Whether you’re a tech enthusiast, a DIYer, or a professional, knowing how to test a connector with a multimeter is a valuable skill.

A multimeter is a versatile tool that allows you to measure voltage, current, and resistance. By using a multimeter, you can quickly and accurately assess the integrity of a connector, ensuring that it is providing an optimal connection for your devices.

In this article, we will guide you through the steps of testing a connector with a multimeter. We will cover the necessary tools, explain the process, and provide tips to help you troubleshoot common issues. So, if you’re ready to become a connector testing pro, let’s dive in!

Inside This Article

Overview

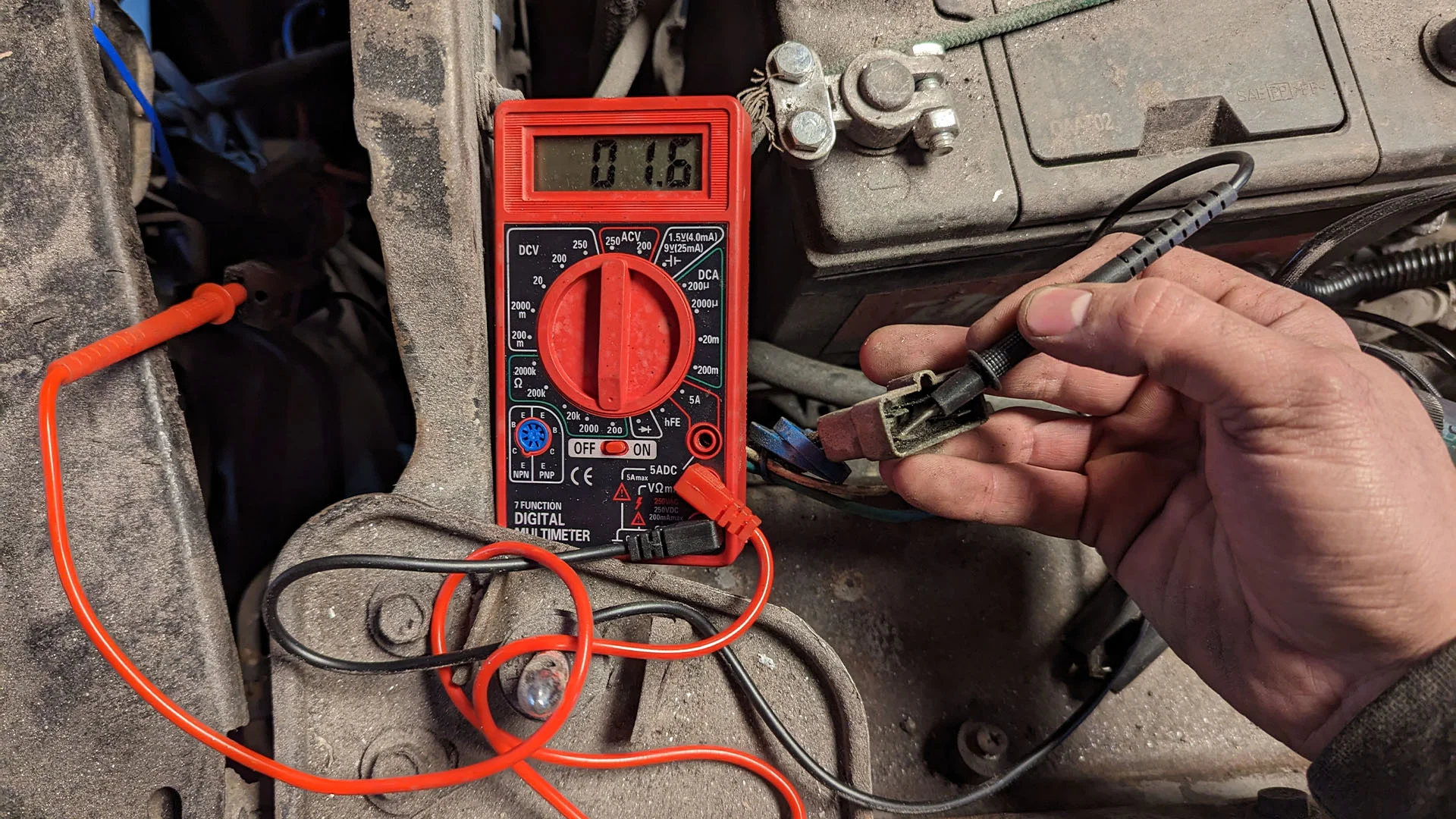

When it comes to testing a connector with a multimeter, understanding the basics is crucial. Whether you’re working on electronic devices, automotive wiring, or any other type of electrical connection, a multimeter is a handy tool that can help you troubleshoot and diagnose potential issues. In this article, we will guide you through the process of testing a connector using a multimeter, so you can ensure proper connectivity and identify any faults.

First, it’s important to gather all the necessary materials before you begin. This will include a multimeter, the connector you want to test, and probe tips or test leads that are compatible with your multimeter. Having these materials ready will make the testing process much more seamless and efficient.

Next, we will walk you through a step-by-step procedure for testing the connector using a multimeter. By following these instructions, you can accurately measure the connectivity and integrity of the connection.

After completing the testing process, you will need to interpret the results obtained from the multimeter. This step is crucial in determining whether the connector is in good condition or if there are any faults or defects that need to be addressed. We will discuss how to interpret the readings and what they mean in order to make an informed assessment of the connector’s health.

By learning how to test a connector with a multimeter, you can make sure that your electrical connections are secure and working as intended. This knowledge will not only save you time and money but will also help you troubleshoot and resolve electrical issues more effectively.

Required Materials

When it comes to testing a connector with a multimeter, you’ll need a few essential materials to get the job done. Here’s a list of items you’ll need:

- Multimeter: The key tool for this task is a multimeter, also known as a volt-ohm meter (VOM). Make sure you have a reliable multimeter on hand to accurately measure voltages, resistances, and other electrical parameters.

- Connector: You’ll need the connector that you want to test. It could be an electrical connector, audio connector, or any other type of connector that you suspect might be faulty.

- Test Leads: The multimeter typically comes with test leads or probes. These are the cables that connect the multimeter to the connector. Ensure that your test leads are in good condition and capable of accurately conducting electrical signals.

- Power Source: In some cases, you may need a power source to provide voltage or current to the connector for testing purposes. This could be a battery or a power supply depending on the requirements of the connector you’re testing.

- User Manual or Datasheet: It’s always a good idea to have the user manual or datasheet for the connector you are testing. This will provide you with important information about the pinout, voltage levels, and other specifications that you need to consider during testing.

Having these materials ready will ensure that you have everything you need to effectively test a connector with a multimeter. Now that you have your materials prepared, let’s move on to the testing procedure.

Testing Procedure

When it comes to testing a connector with a multimeter, there are several steps you need to follow to ensure accurate results. Here’s a step-by-step guide on how to do it:

-

Make sure you have the necessary materials ready, including a multimeter, the connector you want to test, and any additional tools required for the specific connector type.

-

Set the multimeter to the appropriate setting for continuity testing. This is usually indicated by a soundwave or a diode symbol on the multimeter’s dial. Consult the multimeter’s user manual if you’re unsure which setting to use.

-

Insert the multimeter probes into the appropriate ports. One probe should be inserted into the positive port (marked with a “+” symbol) and the other probe into the negative port (marked with a “-” symbol).

-

Ensure that the connector is not connected to any power source or device. This is important to prevent any interference or damage during the testing process.

-

Hold one multimeter probe against one end of the connector, making sure it makes contact with the metal pins or terminals.

-

With the other multimeter probe, touch the corresponding pins or terminals on the opposite end of the connector. Make sure you maintain a stable connection between the probe and the pins/terminals.

-

Observe the multimeter’s display. If the connector is functioning properly and has good continuity, the multimeter will display a low resistance reading or emit a continuous tone, depending on the settings used.

-

If the multimeter displays a high resistance reading or does not emit any sound, it indicates a potential issue with the connector. You may need to inspect the connector for loose connections, damaged pins, or other visible signs of damage.

-

If necessary, repeat the testing process for each pin or terminal on the connector to ensure all connections are properly functioning.

Remember, it’s always a good idea to consult the specific connector’s user manual or documentation for any additional testing instructions or precautions. Following these steps will help you effectively test a connector with a multimeter and identify any potential issues.

Interpreting the Results

Once you have performed the connector test using a multimeter, it is important to know how to interpret the results accurately. Here are a few key points to keep in mind:

- Continuity: If the multimeter displays a reading close to zero or the continuity symbol (a horizontal line with vertical dashes), it indicates that there is a completed circuit and the connector is functioning properly. This means that the electrical connection is established and current can flow unhindered through the connector.

- Open Circuit: On the other hand, if the multimeter displays “OL” or “1” (indicating an open circuit), it means that there is a break or disconnect in the circuit. This could be due to a faulty connector or a broken wire within the connector. In this case, the connector needs to be replaced or repaired to restore the electrical connection.

- Short Circuit: Another possibility is a short circuit, which occurs when there is an unintended connection between two or more conductive elements. If the multimeter displays a very low resistance or a reading close to zero, it indicates a short circuit. This can be caused by a wire touching another wire or metal surface, or a damaged insulation within the connector. A short circuit can be dangerous as it can cause overheating and even lead to electrical fires. In such cases, the connector should be immediately replaced to prevent any hazards.

- Inconsistent Readings: Sometimes, you may encounter inconsistent readings during the connector test. This could indicate a loose connection or a poor contact within the connector. To ensure accurate results, make sure the multimeter probes are securely attached to the connector terminals. You can also try moving or wiggling the connector slightly to see if the readings stabilize. If the readings remain inconsistent, it may be necessary to clean the connector or check for any damage that might be affecting its performance.

Remember, interpreting the results of a connector test with a multimeter requires careful observation and understanding of the readings. If you are unsure or if the results are not clear, it is always recommended to consult a professional or seek assistance from a knowledgeable technician to accurately diagnose and resolve any issues with the connector.

The ability to test a connector with a multimeter is a valuable skill for anyone working with electronics or electrical systems. By using this versatile tool, you can quickly diagnose connectivity issues, identify faulty connectors, and ensure the proper functioning of your devices.

During the testing process, remember to always follow safety protocols, such as turning off the power and wearing appropriate protective gear. With the multimeter set to the appropriate mode and range, carefully place the probes on the connector pins and check for continuity or voltage readings.

By diligently practicing these testing methods, you can troubleshoot connector problems efficiently and effectively, saving both time and money. Whether you’re a professional technician or an enthusiastic DIYer, knowing how to test a connector with a multimeter is an essential skill that will greatly benefit your work in the world of electronics.

FAQs

1. How do I test a connector with a multimeter?

Testing a connector with a multimeter involves a few simple steps. First, set your multimeter to the continuity or resistance mode. Next, insert the connector into the multimeter’s probes. Then, touch the probes to the pins or terminals of the connector. If the multimeter shows a reading or beeps, it indicates that there is continuity or a connection in the connector. If there is no reading or beep, it suggests a problem with the connection.

2. What if my connector has multiple pins or terminals?

If your connector has multiple pins or terminals, you can test each pin or terminal individually using the same method mentioned earlier. This will help you identify any faulty pins or terminals within the connector.

3. Can I test both male and female connectors with a multimeter?

Yes, you can test both male and female connectors with a multimeter. The process is the same for both types. Simply insert the appropriate probe into the connector and touch it to the pins or terminals.

4. Is it necessary to disconnect the connector from the device before testing?

In most cases, it is not necessary to disconnect the connector from the device before testing it with a multimeter. However, if you suspect that the device is causing a faulty connection, it may be helpful to disconnect the connector and test it separately to isolate the issue.

5. What should I do if I find a faulty connection in the connector?

If you find a faulty connection in the connector during testing, the first step is to check for any visible signs of damage such as bent pins or loose terminals. If there are no visible issues, you may need to replace the connector or seek professional help, depending on the complexity of the problem.